Chlorella, cultivating method and application thereof in producing biodiesel

A technology of biodiesel and cultivation method, which is applied in the field of chlorella and its cultivation method and its application in biodiesel production, can solve the problems of high production cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

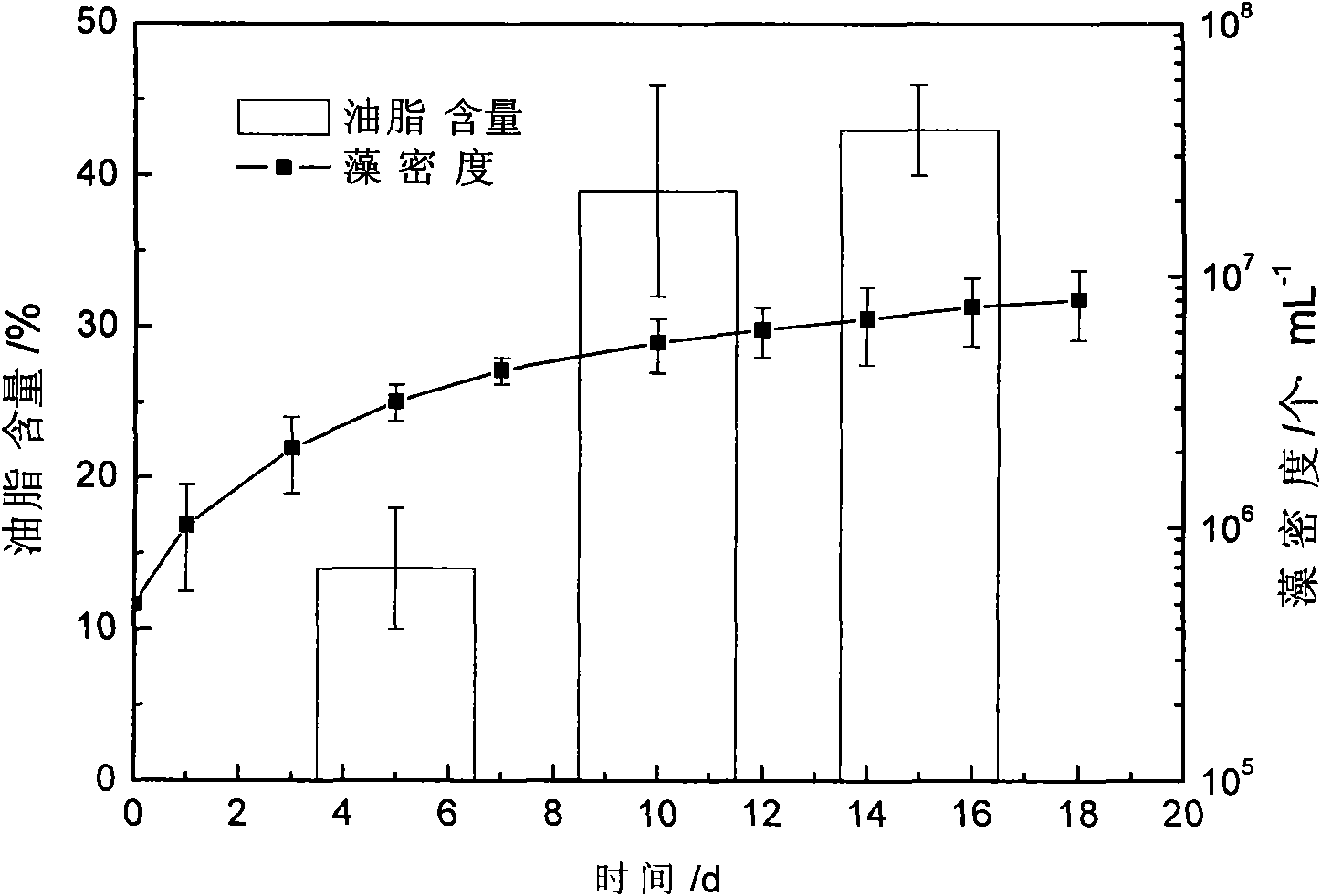

[0025] Chlorella algae species YJ1 was inoculated into the secondary effluent of Beijing Gaobeidian Sewage Treatment Plant with an initial inoculation density of 5×10 4 pcs mL -1 . The light-dark ratio is 12h:12h, the temperature is 25°C, the relative humidity is 75%, and the light intensity is 1100lux, and it is cultivated for about 18 days. At different times of cultivation, the growth curve and oil content of the chlorella are measured. Centrifuge at 6000rpm for 10min after the cultivation, and harvest Chlorella.

[0026] The result is as figure 1 As shown, the maximum algal density of chlorella growing in the secondary effluent of the urban sewage can be as high as 10 7 pcs mL -1 ; The oil percentage can be as high as 43%.

Embodiment 2

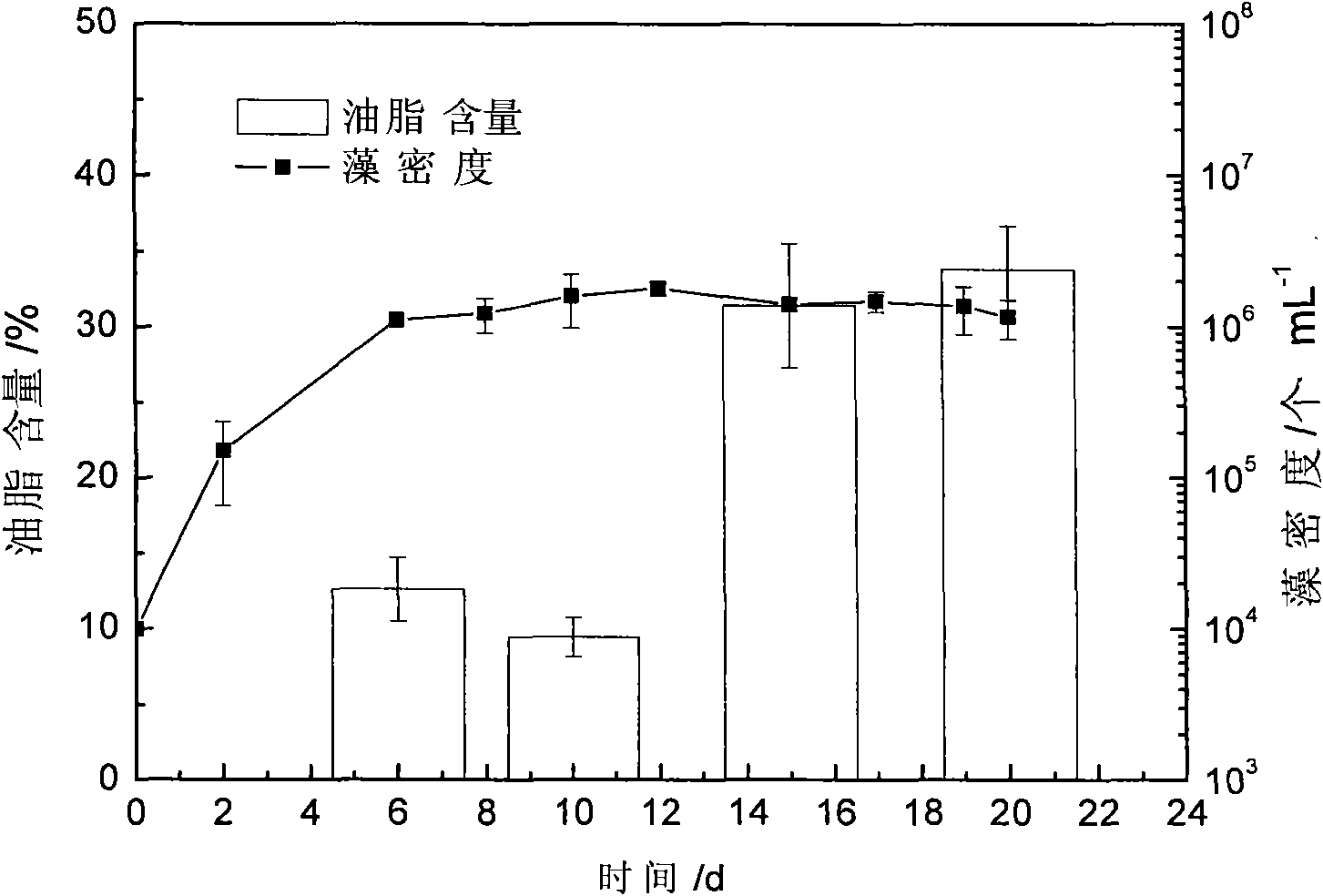

[0028] Chlorella algae species YJ1 was inoculated into the secondary effluent of Qinghe Wastewater Treatment Plant with an initial inoculation density of 1×10 4 pcs mL -1 . The chlorella was cultured for about 20 days under the conditions of a light-dark ratio of 14h:10h, a temperature of 27°C, a relative humidity of 70%, and a light intensity of 1300 lux, and the growth curve and oil content of the chlorella were measured. Centrifuge at 6000rpm for 10min after the cultivation, and harvest Chlorella.

[0029] The result is as figure 2 As shown, the maximum algal density of chlorella growing in the secondary effluent of the urban sewage can be as high as 10 6 pcs mL -1 ; The oil percentage can be as high as 43%.

Embodiment 3

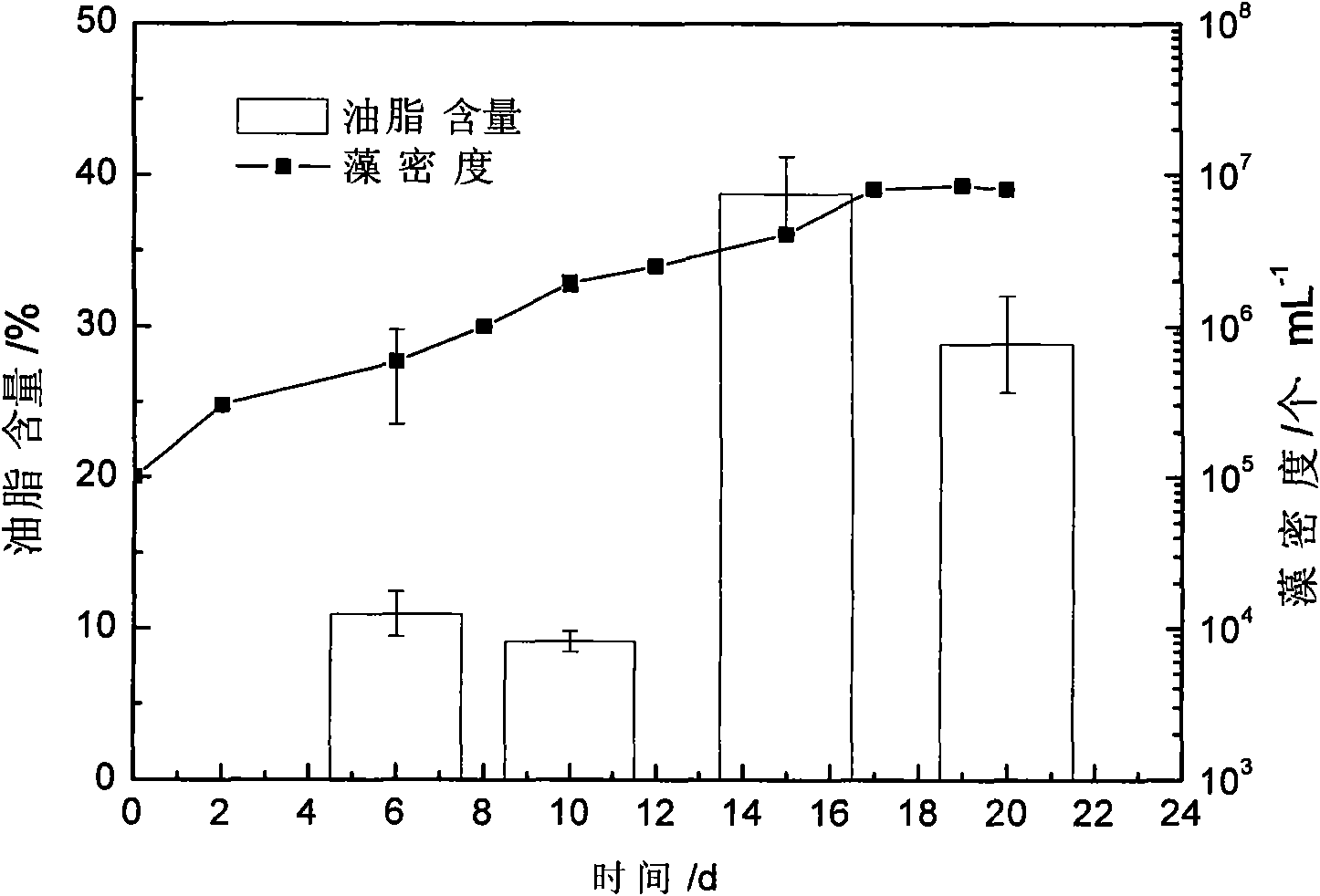

[0031] Chlorella species YJ1 was inoculated into the secondary effluent of Jiuxianqiao Sewage Treatment Plant with an initial inoculation density of 1×10 5 pcs mL -1 . The chlorella was cultured for about 21 days under the conditions of a light-dark ratio of 13h:11h, a temperature of 22°C, a relative humidity of 80%, and a light intensity of 800 lux, and the growth curve and oil content of the chlorella were measured. Centrifuge at 6000rpm for 10min after the cultivation, and harvest Chlorella.

[0032] The result is as image 3 As shown, the maximum algae density of chlorella growing in the secondary effluent of urban sewage can reach 10 7 pcs mL -1 ; The oil percentage can be as high as 43%.

[0033] The chlorella obtained in the above examples can be used to produce biodiesel through transesterification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com