Process for photocatalytic treatment of industrial waste water

A technology of industrial wastewater and photocatalysis, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, energy wastewater treatment, etc., can solve the problems of non-reporting, etc., and achieve the effect of cost reduction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

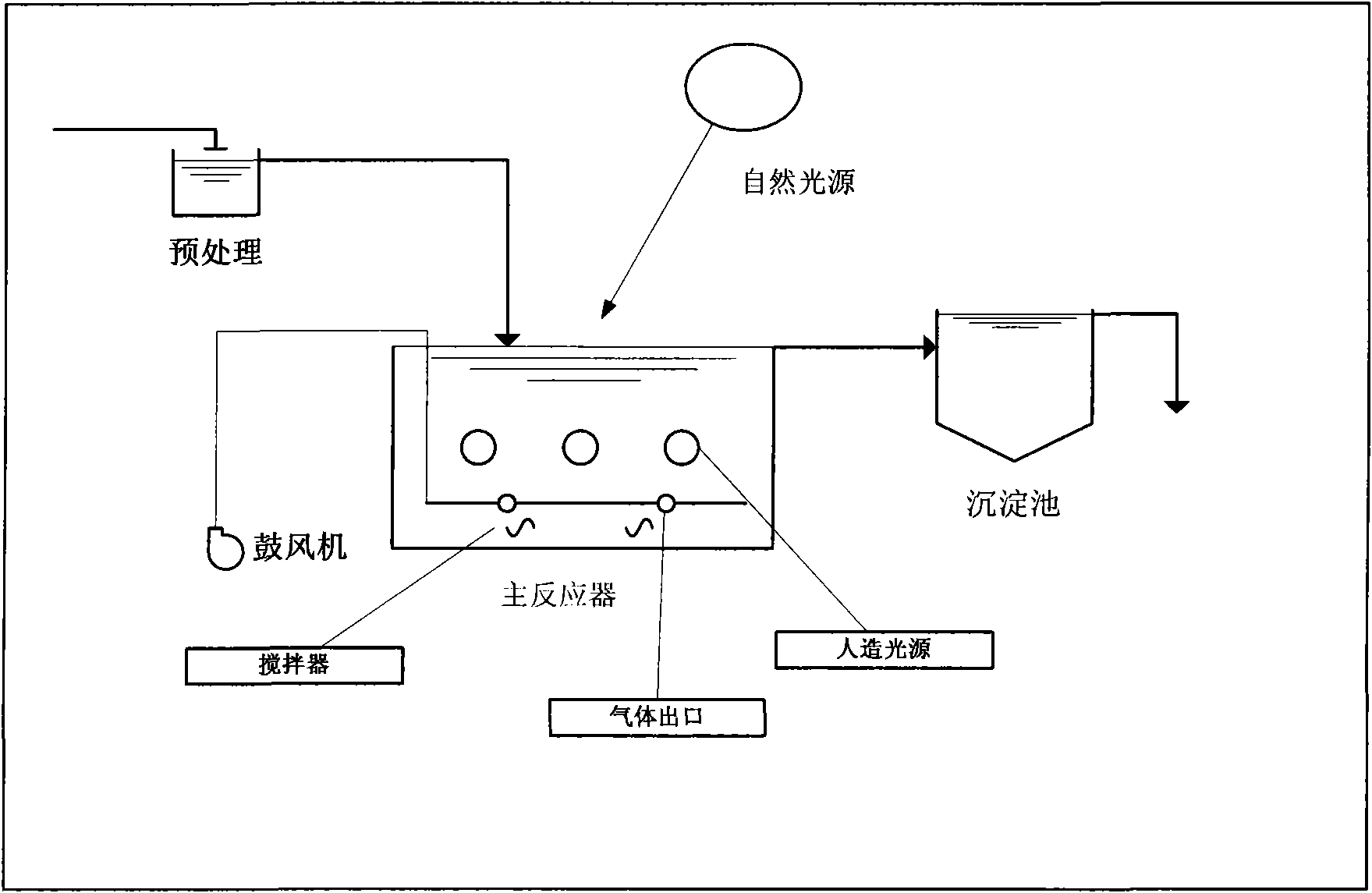

Image

Examples

Embodiment 1

[0017] Industrial wastewater to be treated: acrylic acid wastewater

[0018] 1) Pretreatment: After removing the solid pollutants in the circulating wastewater by filtration, add HCl to adjust the pH=2 to 3;

[0019] 2) After the pretreated wastewater (COD fluctuates between 25 000 and 30 000ppm) is introduced into the main reactor, the photocatalyst non-supported TiO is added at a ratio of 12kg / ton of wastewater 2 , H 2 o 2 The content is 0-10kg / ton of wastewater, and air is blown into the wastewater at the same time. The light source is irradiated by low-pressure mercury lamp and sunlight at the same time, and the wastewater in the reaction system is always in a stirring state;

[0020] 3) After the degradation is completed, the regenerated water flows out from the upper part of the main reactor, and the regenerated water takes out the catalyst and separates it through natural sedimentation in the sedimentation tank.

[0021] The COD of the degraded recycled water is lowe...

Embodiment 2

[0023] Industrial wastewater to be treated: acrylic acid wastewater

[0024] 1) Pretreatment: After removing the solid pollutants in the wastewater by filtration, add HCl to adjust the pH=1 to 2;

[0025] 2) Introduce the pretreated wastewater (COD fluctuates between 25,000 to 30,000ppm) into the main reactor, and add non-supported metal-doped TiO at a ratio of 20 to 30kg / ton of wastewater 2 and non-supported non-metal doped TiO 2 , and at the same time add H at a ratio of 1 to 5kg / ton of wastewater 2 o 2 and 20-45kg of FeCl 3 Forming Fenton’s reagent, blowing air into the wastewater, the light source is irradiated by low-pressure mercury lamp and sunlight at the same time, and the wastewater in the reaction system is always in a stirring state;

[0026] 3) After the degradation is completed, the regenerated water flows out from the upper part of the main reactor, and the regenerated water takes out the catalyst and separates it through natural sedimentation in the sedimen...

Embodiment 3

[0029] Industrial wastewater to be treated: starch wastewater

[0030] 1) Pretreatment: settle the suspended solids in the wastewater by sedimentation, then add sulfuric acid to adjust the pH of the wastewater to 4-5;

[0031] 2) Introduce the pretreated wastewater (COD fluctuates between 7000-15000ppm) into the reaction system, and add photocatalyst-loaded metal-doped TiO at a ratio of 5kg / ton of wastewater 2 , air is blown into the wastewater, the light source is irradiated by sunlight, and the wastewater in the reaction system is always in a stirring state;

[0032] 3) After the degradation is completed, the regenerated water flows out from the upper part of the main reactor, and the regenerated water takes out the catalyst and separates it through natural sedimentation in the sedimentation tank.

[0033] The COD of the degraded recycled water is lower than 100ppm, meeting the national discharge standard. Compared with the technology, chemical flocculation and precipitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com