Control circuit of heater control valve

A control circuit and control valve technology, applied in electrical program control, program control in sequence/logic controllers, control systems, etc., can solve problems such as short power supply life, and achieve problems such as difficulty in charging, convenient installation, and convenient management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below.

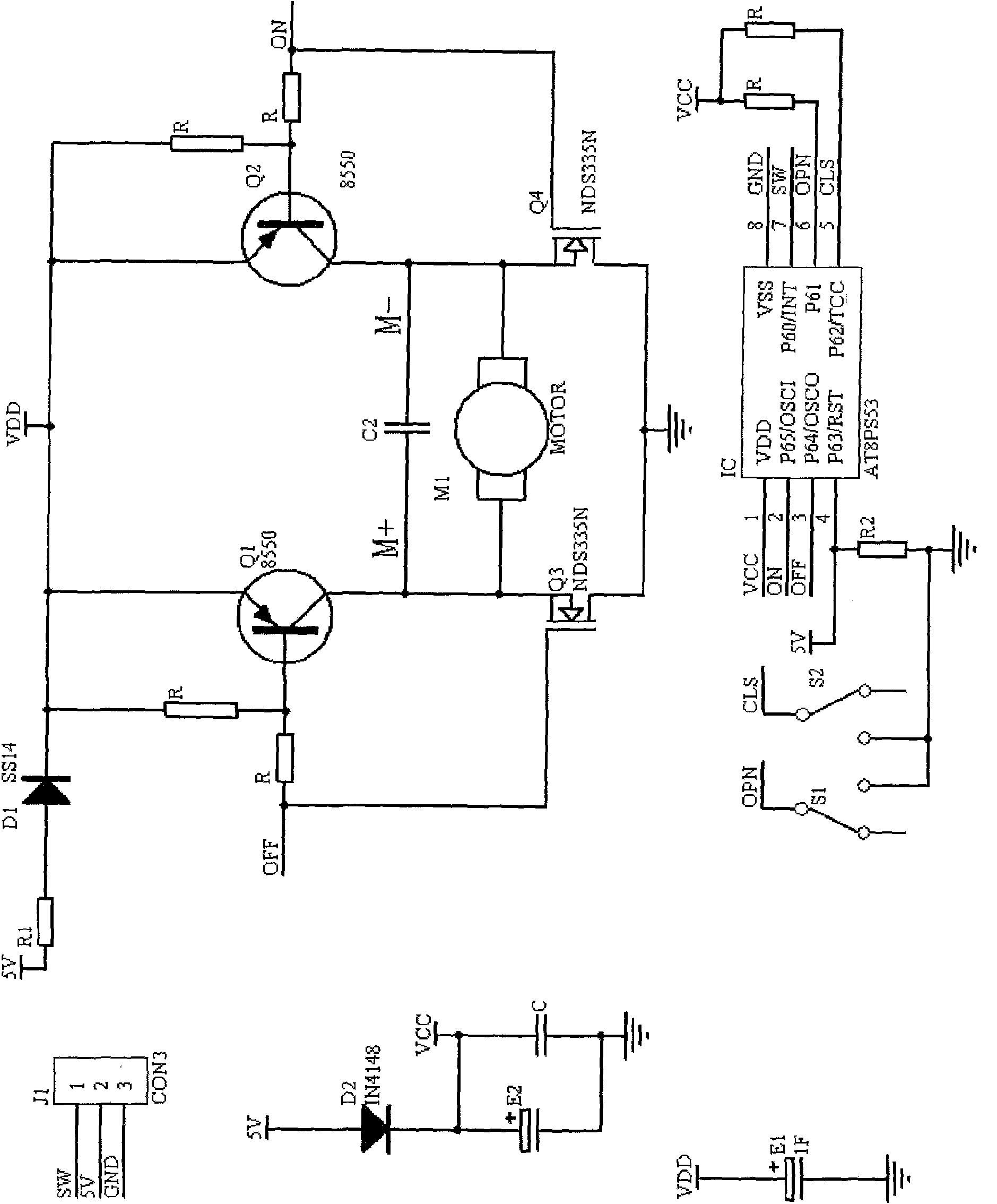

[0031] A heating control valve control circuit, such as figure 1 shown, including:

[0032] A motor M1, used to control the opening and closing of the switch;

[0033] A microprocessor IC, the microprocessor adopts AT series, such as AT8PS53, which is used to receive signals and drive the motor M1 to rotate;

[0034] A supercapacitor E1 stores electric energy and provides electric energy for the motor M1 after power off.

[0035] The P63 pin of the microprocessor is connected to the high potential and grounded through the pull-down resistor R2. The ground wire is also connected with the open limit switch S1 and the close limit switch S2 in parallel. OFF pin, P60 pin is connected to the thermostat control line.

[0036] Between the ON pin and the OFF pin is a motor drive circuit, including a motor M1, two transistors Q1 and Q2 (model 8550), two field effect transistors Q3 and Q4 (model NDS335N)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com