Evacuation device for mandril of perforator

A piercing machine and ejector technology, applied in the field of steel rolling machinery, can solve the problems of occupying production time, affecting the quality of steel pipes, affecting product quality, etc., and achieve the effects of improving quality, increasing output, and improving process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

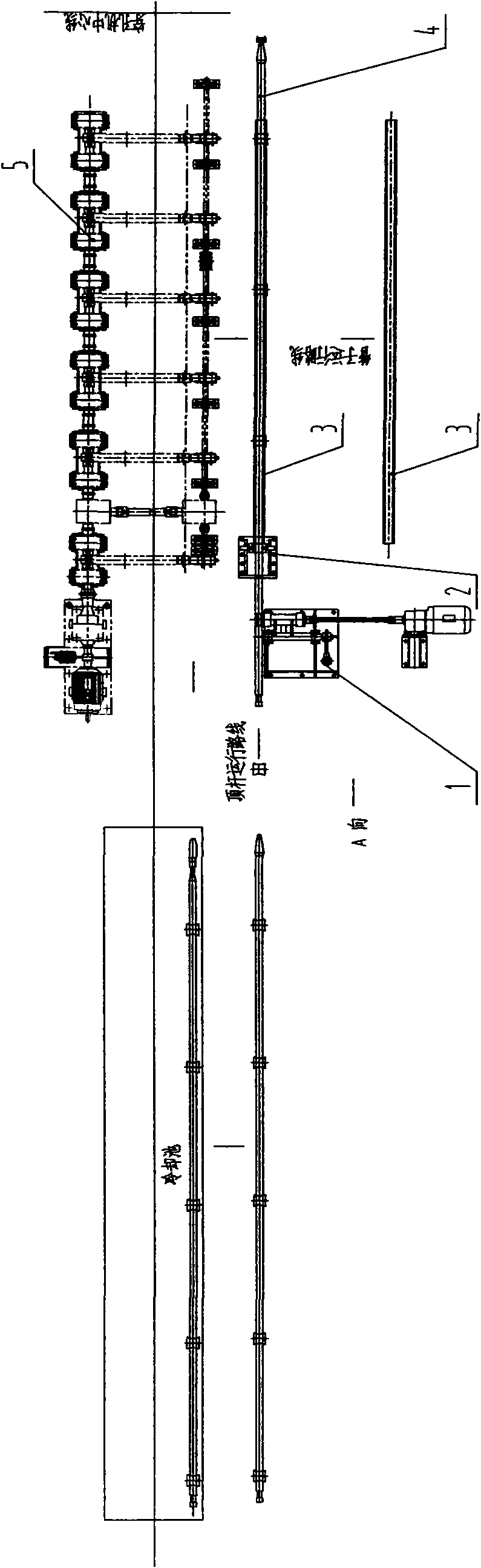

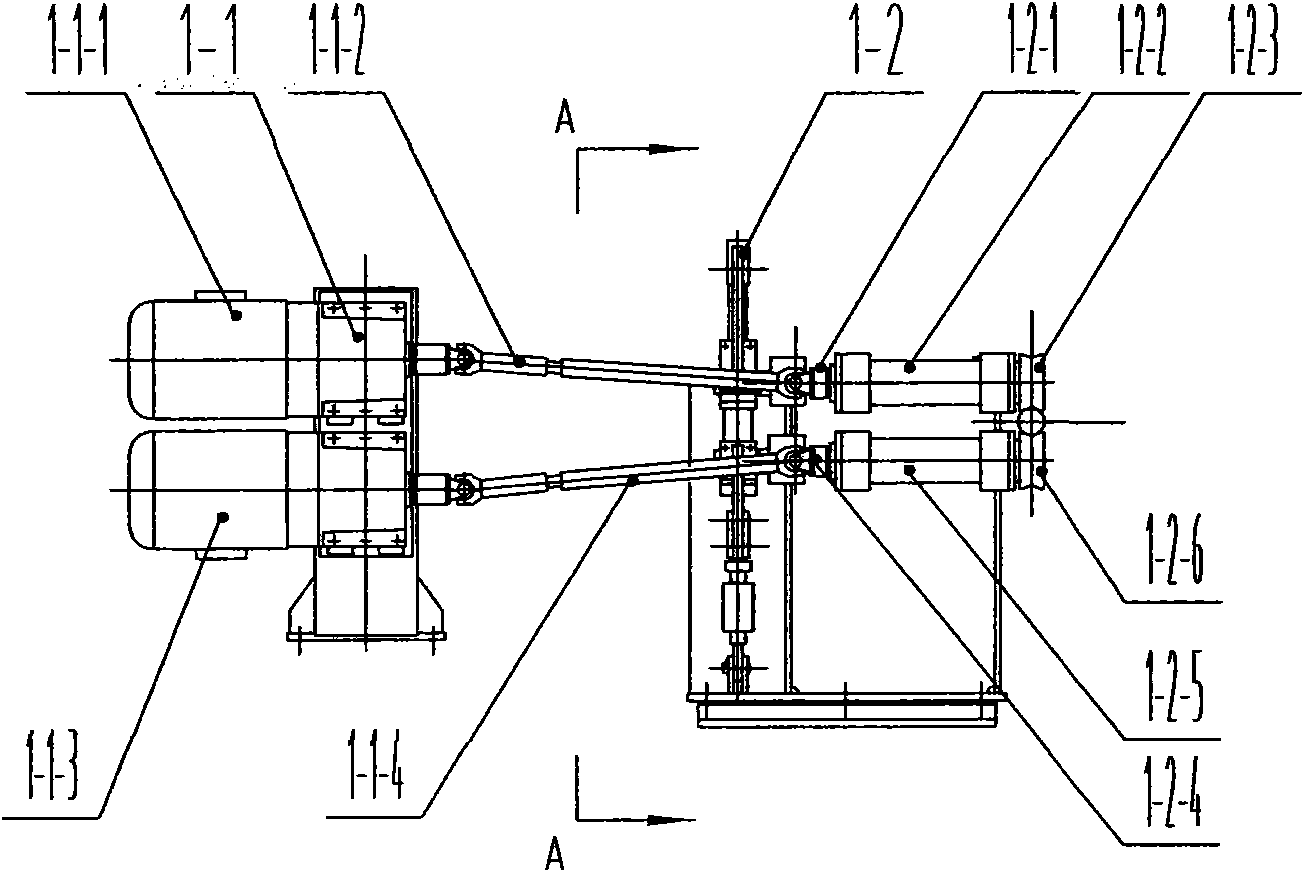

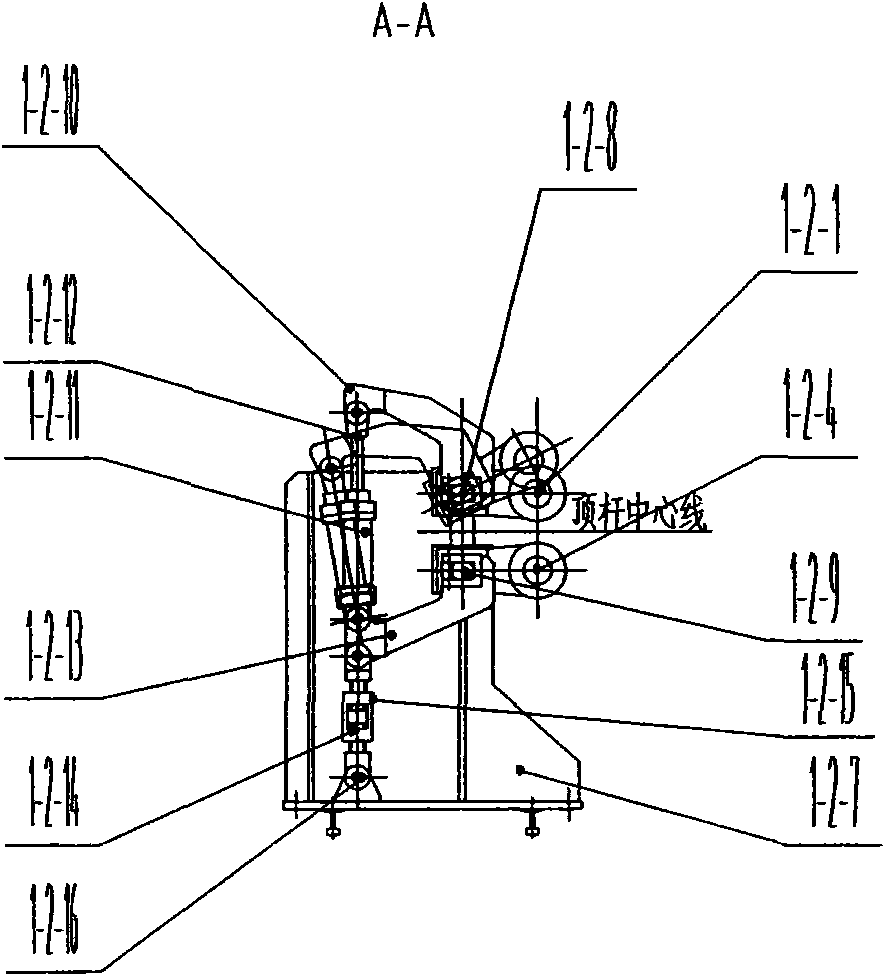

[0017] Such as figure 1 , 2 , as shown in 3,

[0018] A disengagement device for the ejector rod of a piercing machine, which is composed of a pinch device 1 and a baffle plate 2; the pinch device 1 is composed of a transmission device 1-1 and a pinch roller mechanism 1-2, and the transmission device is for The pinch roller mechanism is powered.

[0019] The No. 1 motor 1-1-1 of the transmission device 1-1 is connected with the upper pinch roller shaft 1-2-1 of the pinch roller mechanism through the No. 1 universal joint shaft 1-1-2, and the upper clamp The other end of the delivery roller shaft 1-2-1 is connected to the upper pinch roller 1-2-3; the No. 2 motor 1-1-3 of the transmission device 1-1 passes through the No. 2 universal joint shaft 1-1- 4 is connected with the lower pinch roller shaft 1-2-4 of the pinch roller mechanism, and the other end of the lower pinch roller shaft 1-2-4 is connected with the lower pinch roller 1-2-6.

[0020] The upper pinch roller shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com