Multiple-effect biological solid catalyst used for reclaimed water treatment and the preparation method thereof

A technology of biological solids and production methods, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, water/sewage treatment, etc., can solve the problems of increasing biomass, insufficient supply of nutrients and oxygen, and affecting the efficiency of sewage treatment, etc., to improve Effect of reducing biochemical efficiency and bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

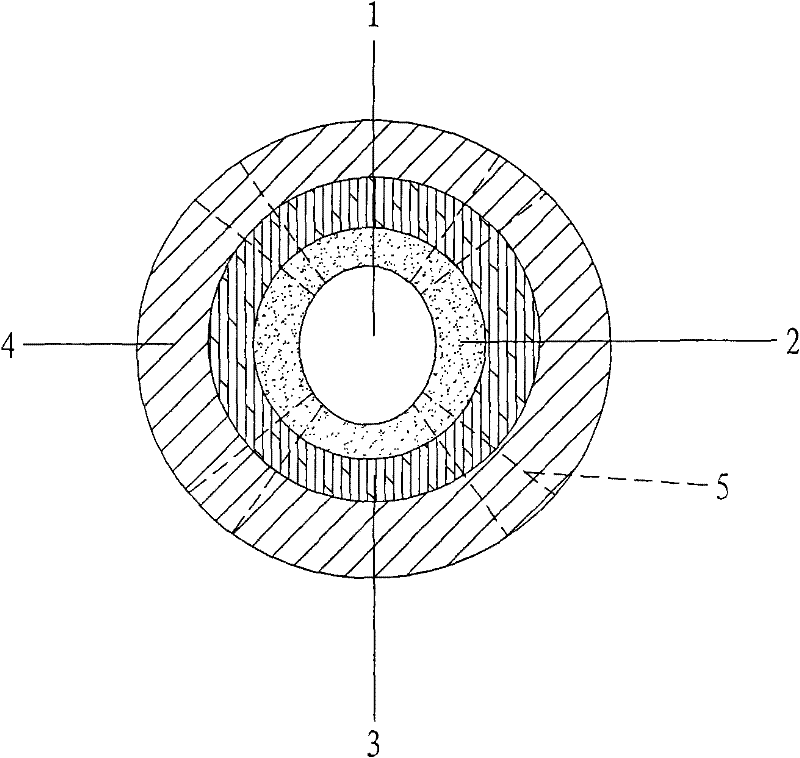

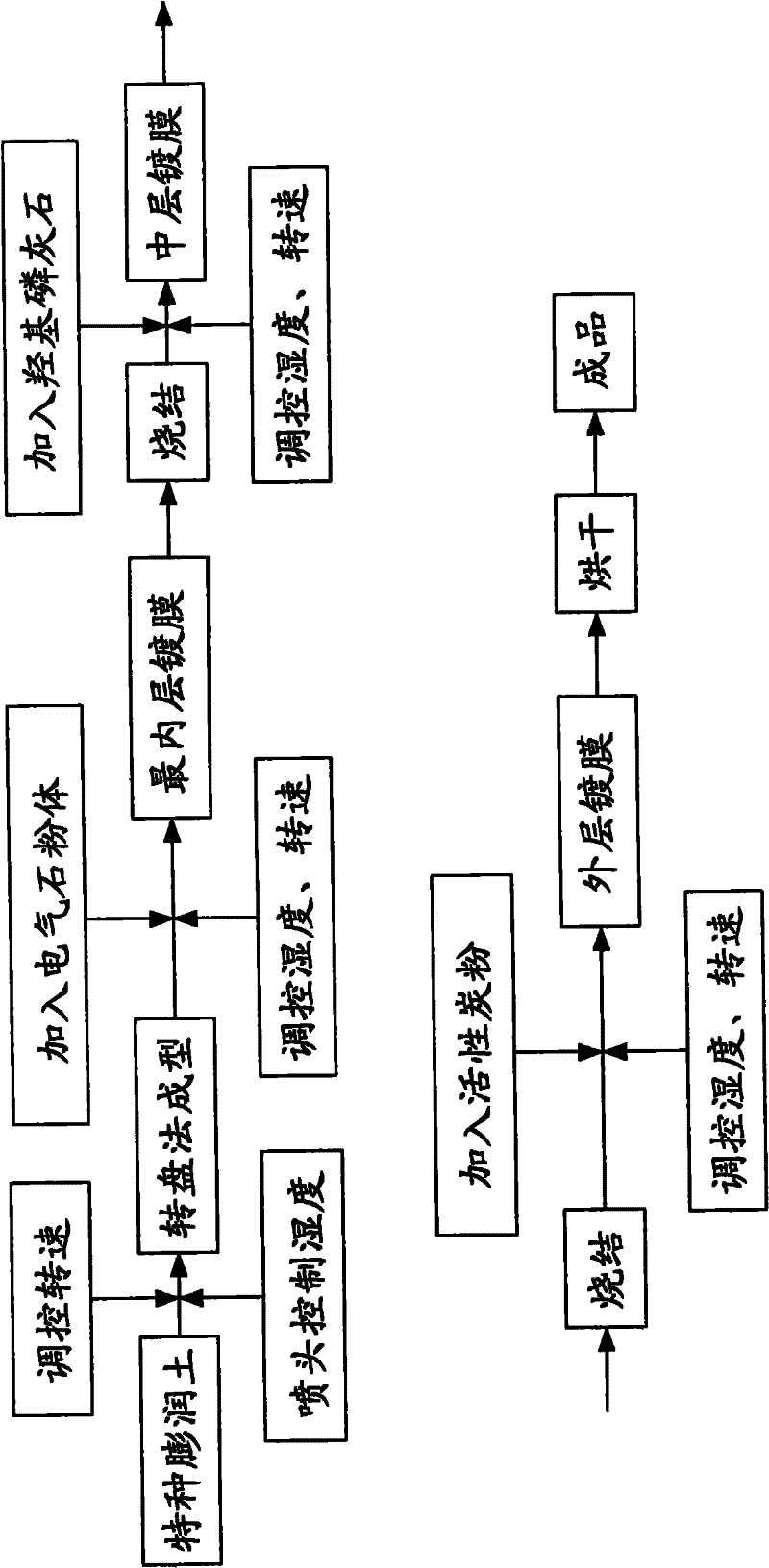

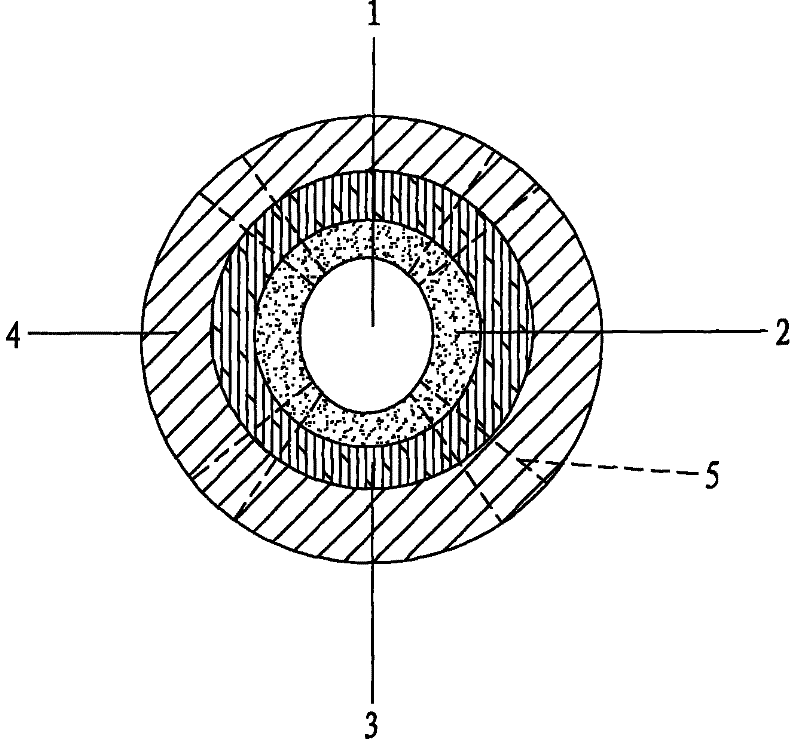

[0033] When the present invention is implemented, as figure 1 and figure 2 As shown, the specific steps are as follows:

[0034] First, take 1 mm of bentonite and pour it into the turntable machine, control the humidity at 75% through the nozzle, control the speed at 20 rpm, and form the turntable for 15 minutes to obtain the carrier 1.

[0035] Then, add 100 nanometers of activated nano-tourmaline powder, control the humidity to 75%, rotate at 50 rpm, run for 15 minutes, complete the innermost coating 2, and sinter at 600°C for 4 hours.

[0036] Then, put it back into the turntable, control the humidity to 70%, rotate at a speed of 50 rpm, replace the coating material with 300nm hydroxyapatite, run for 15 minutes, complete the middle layer coating 3, and sinter at 400°C for 3 hours.

[0037] Finally, the coating material is replaced with activated carbon powder of 1 micron, the rotating speed is 50 rpm, and the humidity is controlled at 70%. After running for 20 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com