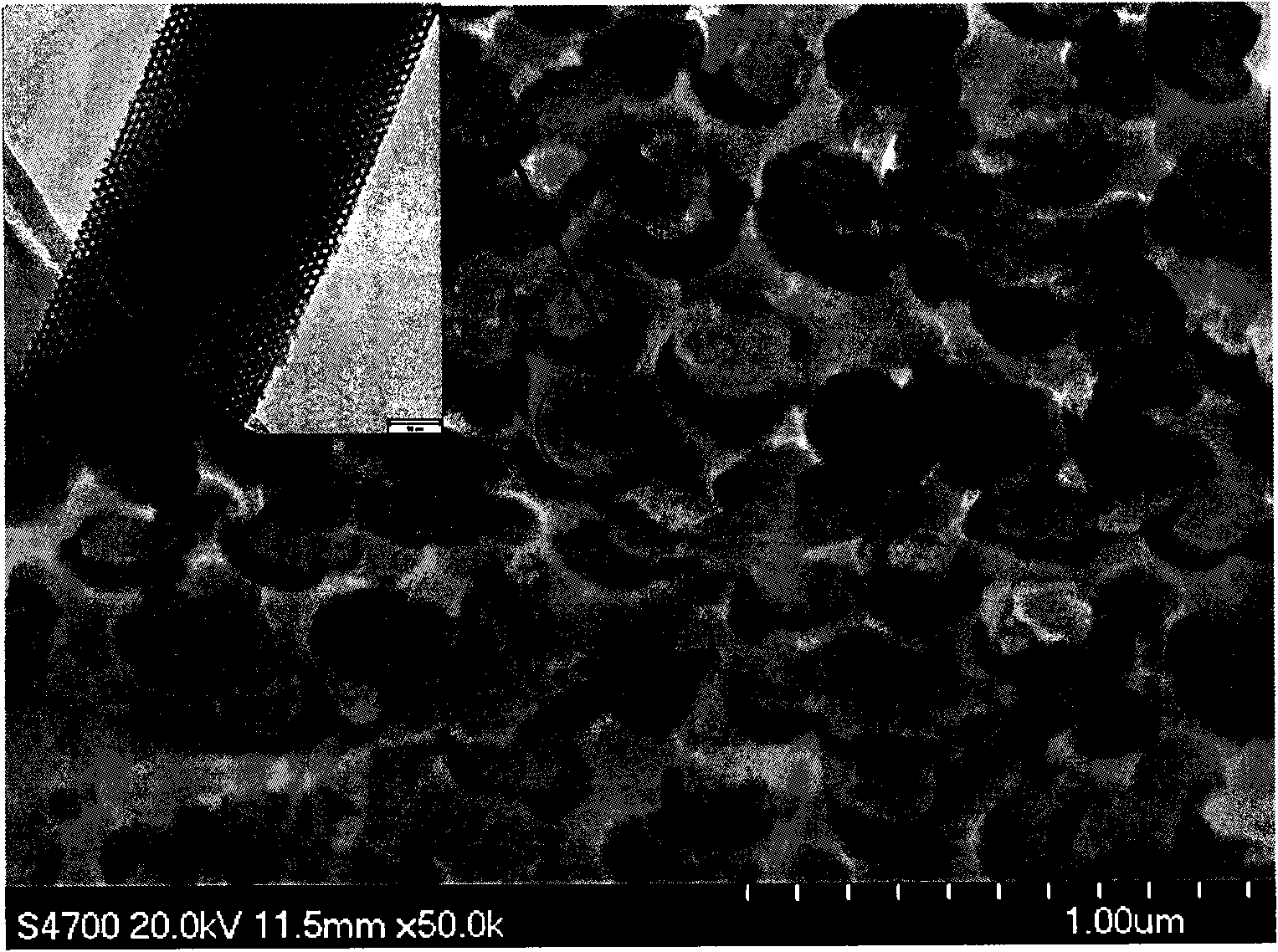

Directional grown mesoporous adsorption material with controllable structure and preparation method thereof

An adsorption material and mesoporous technology, applied in chemical instruments and methods, other chemical processes, silicon compounds, etc., can solve the problems of lack of monolithic structure and poor order of pore structure, and achieve uniform size distribution and regular pore structure Orderly, easy-to-apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of silicon oxide precursor solution

[0020] Dissolve 0.687g polyvinyl ether-polypropylene ether-polyvinyl ether block copolymer (P123) in a mixture of 4.8g ethanol and 1.2g 0.2M HCl at room temperature to form a transparent and uniform P123 solution. Add 0.05 g of toluene, and stir for 2 hours. 2.08 g of ethyl orthosilicate was added dropwise into the solution and stirred for 1 hour.

[0021] (2) Composite of silicon oxide and aluminum oxide

[0022] An anodic aluminum oxide film with a diameter of 47 mm and a pore size of 200 nm is immersed in the silicon oxide precursor solution in step (1), and volatilized under vacuum for 1 hour. The aluminum oxide film was taken out and naturally crystallized for 1 day.

[0023] (3) Post-treatment of silica-alumina composite structure

[0024] 60mL of ethanol was refluxed for 12 hours to extract the block copolymer P123, and replaced with new ethanol for another 12 hours of extraction. Dry at room temperature....

Embodiment 2

[0027] (1) Preparation of silicon oxide precursor solution

[0028] Dissolve 1g of polyvinyl ether-polypropylene ether-polyvinyl ether block copolymer (P123) in a mixture of 5g of ethanol and 1g of 0.2M HCl at room temperature to form a transparent and uniform P123 solution. Add 0.15 g of mercaptopropyltrimethoxysilane, and stir for 2 hours. 2.08 g of ethyl orthosilicate was added dropwise into the solution and stirred for 1 hour.

[0029] (2) Composite of silicon oxide and aluminum oxide

[0030] An anodic aluminum oxide film with a diameter of 47 mm and a pore size of 200 nm is immersed in the silicon oxide precursor solution in step (1), and volatilized under vacuum for 1 hour. The aluminum oxide film was taken out and naturally crystallized for 1 day.

[0031] (3) Post-treatment of silica-alumina composite structure

[0032] 60mL of ethanol was refluxed for 12 hours to extract the block copolymer P123, and replaced with new ethanol for another 12 hours of extraction. ...

Embodiment 3

[0035] (1) Preparation of silicon oxide precursor solution

[0036] Dissolve 1g of polyvinyl ether-polypropylene ether-polyvinyl ether block copolymer (P123) in a mixture of 5g of ethanol and 1g of 0.2M HCl at 35°C to form a transparent and uniform P123 solution. Add 0.05 g of trimethylbenzene, and stir for 2 hours. 2.08 g of ethyl orthosilicate was added dropwise into the solution and stirred for 1 hour.

[0037] (2) Composite of silicon oxide and aluminum oxide

[0038] An anodic aluminum oxide film with a diameter of 47 mm and a pore size of 200 nm is immersed in the silicon oxide precursor solution in step (1), and volatilized under vacuum for 1 hour. The aluminum oxide film was taken out and naturally crystallized for 1 day.

[0039] (3) Post-treatment of silica-alumina composite structure

[0040] 60mL of ethanol was refluxed for 12 hours to extract the block copolymer P123, and replaced with new ethanol for another 12 hours of extraction. Dry at room temperature. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com