Direct manufacturing method of customized lingual orthodontic retainer by selective laser melting

A technology of selective laser melting and manufacturing method, applied in laser welding equipment, manufacturing tools, orthodontics and other directions, can solve the problems of failure to maintain, patient discomfort, affecting the preservation effect, etc., to achieve a short manufacturing cycle, a wide range of applications, Process saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

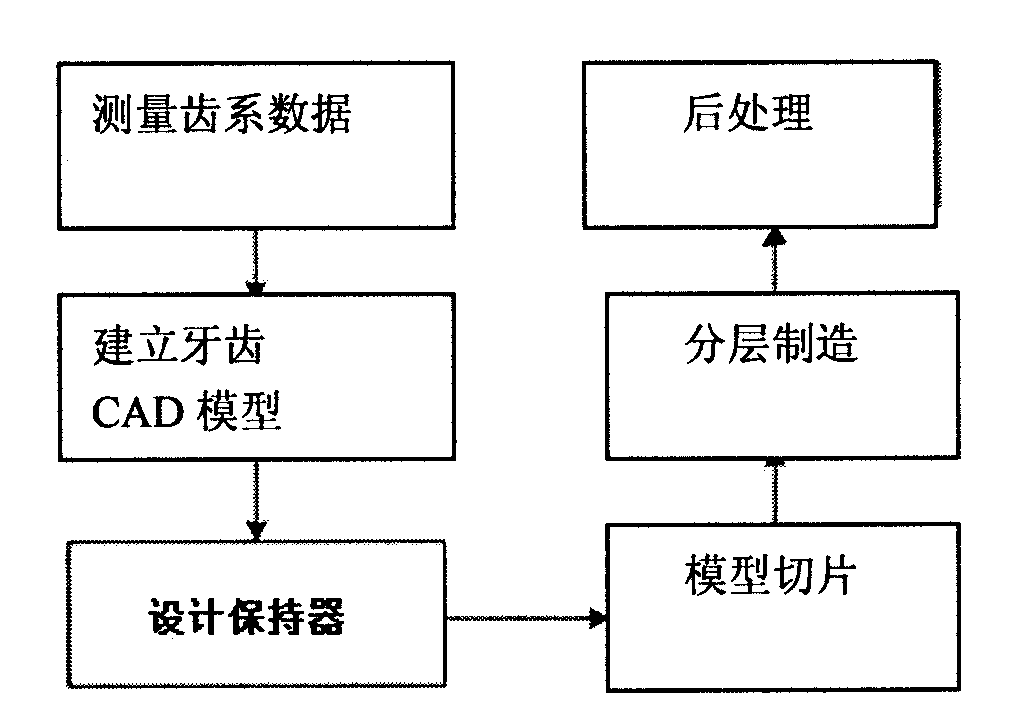

[0036] like figure 1 As shown, the process flow of the selective laser melting direct manufacturing method of the customized lingual orthodontic retainer of the present invention is:

[0037] (1) Measuring the dentition data to obtain the shape and structure parameters of the tooth 1; the measurement of the dentition data may use a non-contact three-dimensional scanner to directly scan the tooth 1, or first obtain a model of the tooth 1 for measurement.

[0038] (2) According to the dentition data of the tooth 1, adopt the method of reverse engineering (Reverse Engineering) to establish as figure 2 The shown three-dimensional CAD model of the tooth 1 is stored in the computer in STL format for subsequent technical processing.

[0039] (3) if image 3 As shown, according to the requirements of orthodontics and the shape characteristics of the teeth 1, a three-dimensional CAD structural model of a single lingual retainer 2 is designed by computer; the design of the three-dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com