Trimming stand

A technology for trimming table and supporting table, applied in the field of solar cells, can solve problems such as fragmentation, complicated operation, and component landing, and achieve the effect of avoiding landing, simplifying the operation process, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

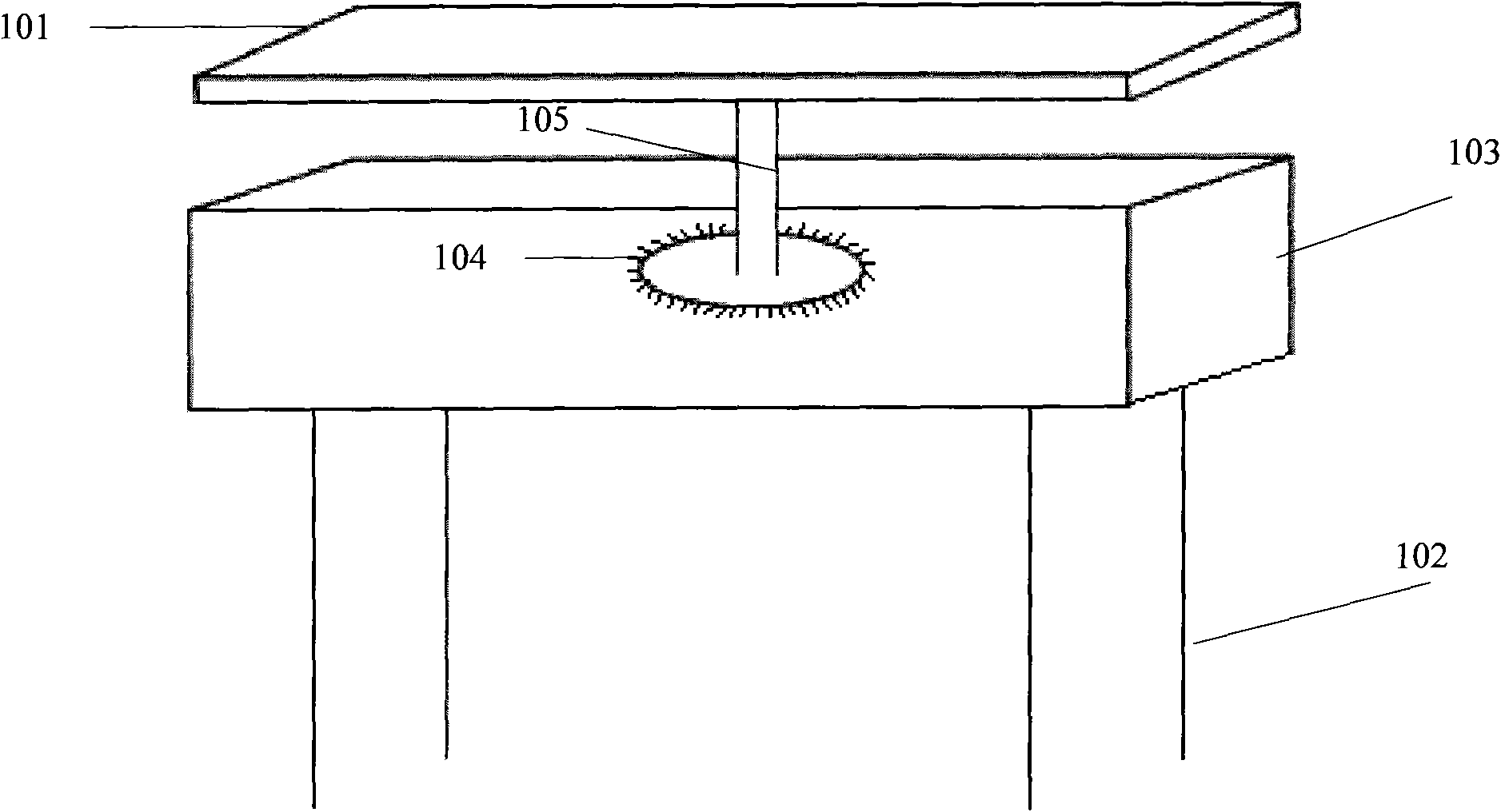

[0034] figure 1 It is a structural schematic diagram of Embodiment 1 of the edge trimming table of the present invention, the edge trimming table includes: a support body 101 for placing solar cell modules, the edge trimming table is also provided with a rotating device 103 connected to the support body 101, The rotating device 103 can selectively drive the supporting body 101 to rotate, and the trimming table further includes a supporting frame 102 for supporting the supporting body 101 and the rotating device 103 .

[0035] The so-called "optional" means that due to the limitation of the operating environment, the rotation direction of the support body 101 can be limited to only clockwise rotation or counterclockwise rotation. In order to meet the needs of such a rotation operation, this embodiment provides a corresponding technical solution. Since the supporting body 101 is required to perform one-way rotation, including clockwise rotation or counterclockwise rotation, the...

Embodiment 2

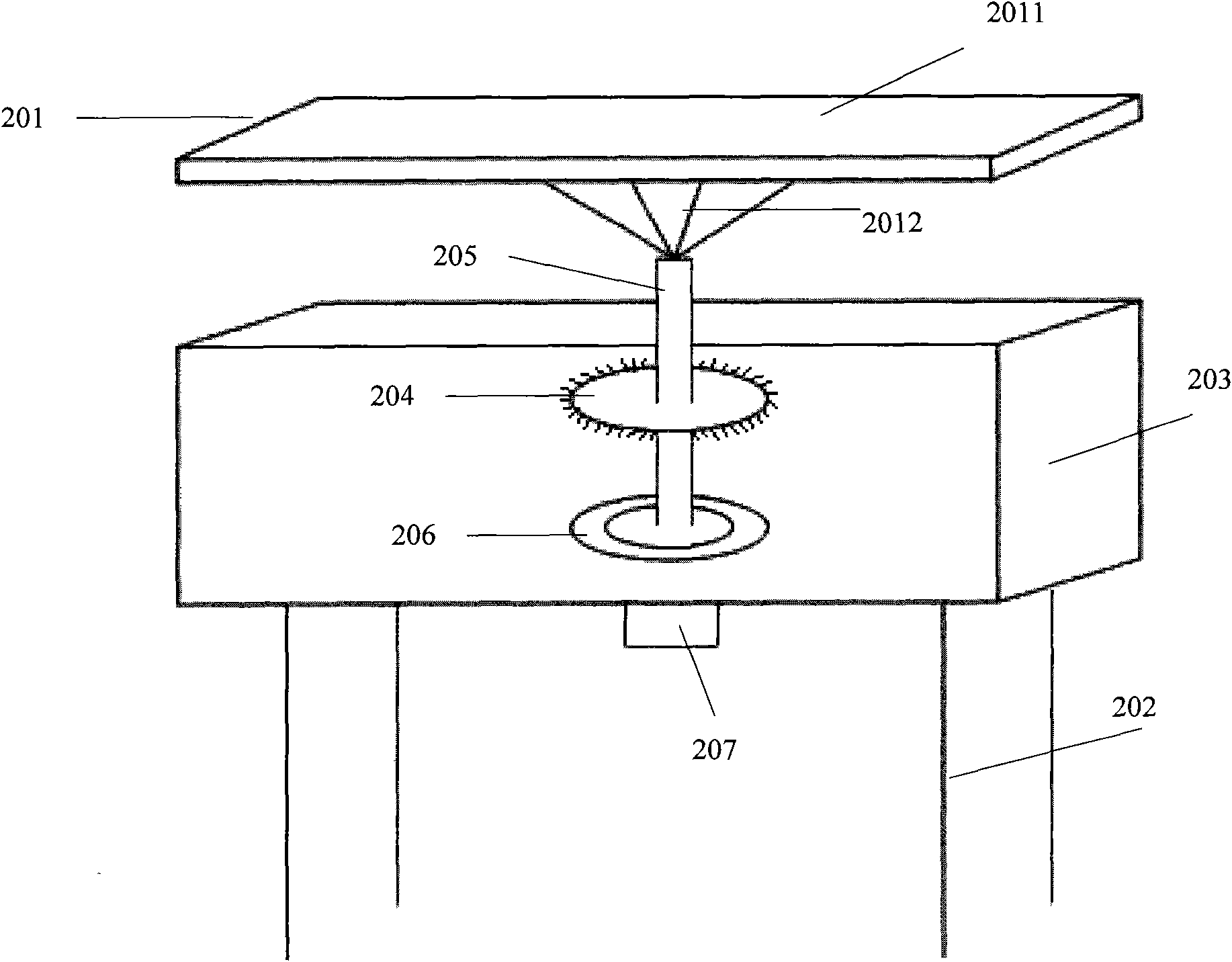

[0043] Such as figure 2 As shown, in the rotating device 203, the bearing mechanism 206 is installed on the main shaft 205 connecting the ratchet mechanism 204 and the support body 201, and is used to slow down the friction force when the ratchet wheel of the ratchet mechanism 204 rotates. 204 may be a one-way ratchet mechanism or a two-way ratchet mechanism.

[0044] In this embodiment, the support specifically includes: a support table 2011 and a support rod 2012 connected to the support table 2011; the support rod 2012 is used to support the support table 2011; the support table 2011 is used to place the the solar cell module.

[0045] In order to increase the stability of the supporting platform 2011, the supporting rod 2012 should have sufficient bearing capacity and a reasonable structure, so that the supporting platform 2011 is stable and reliable. In this regard, the trimming table in this embodiment has at least two support rods 2012, one end of each support rod 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com