Mercury vapour generation method and device

A generating device and mercury vapor technology, which is applied in the field of mercury vapor generation by liquid cathode discharge, can solve the problems of hindering the reduction reaction, failing to realize the reduction of organic mercury, and not being able to use flow injection analysis, so as to achieve small matrix interference and save energy. Effects of analysis steps and time, reduction of reagent loss and contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

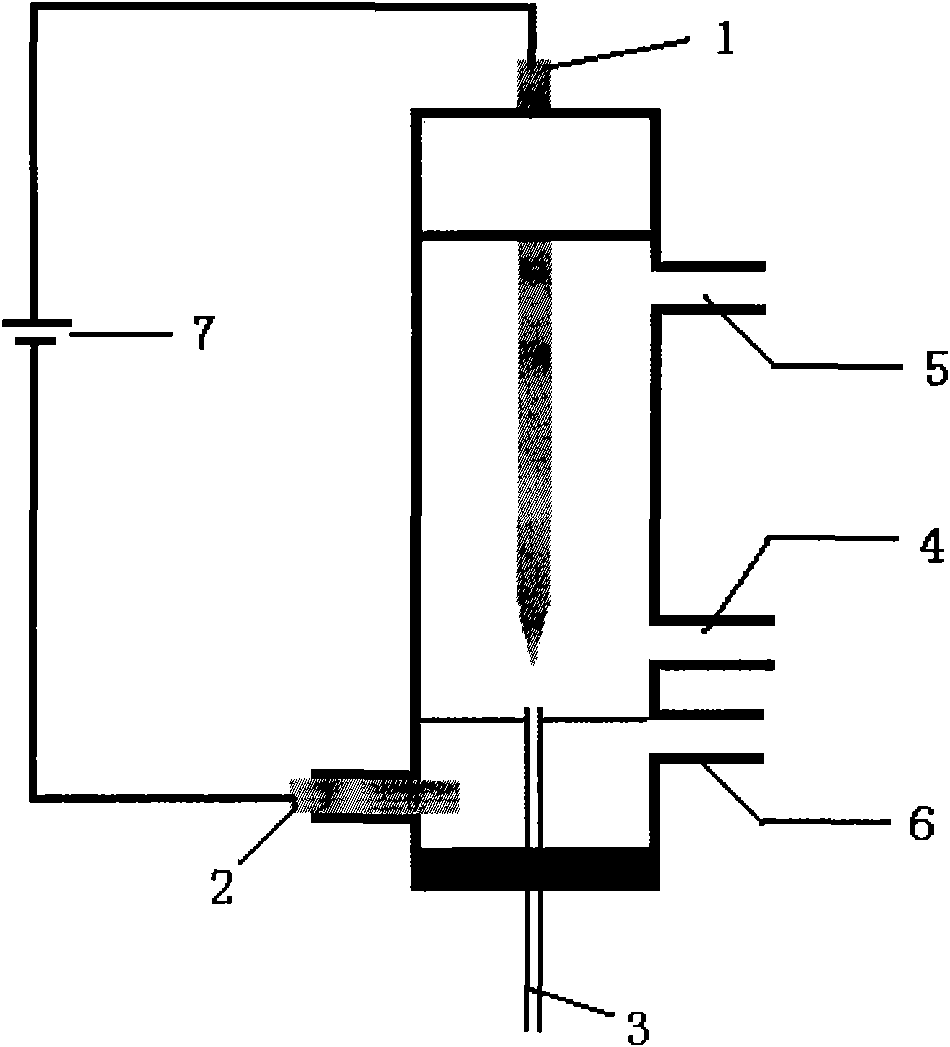

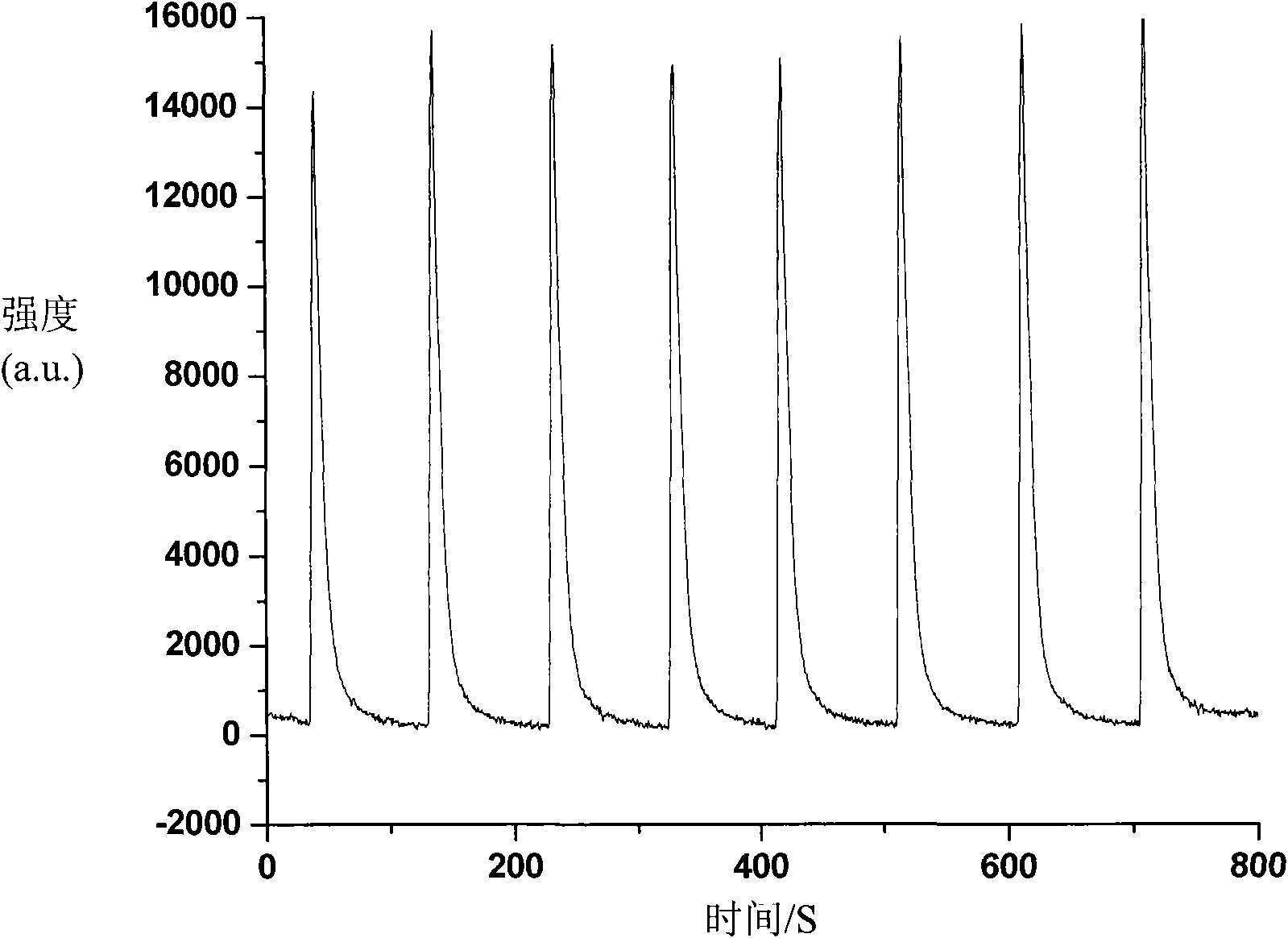

[0023] A tungsten rod is selected as the metal anode, and the diameter of the discharge end is 1 mm. The cathode material is platinum wire. The distance between the tungsten electrode and the capillary is 1 mm, and the inner diameter of the capillary is 0.1 mm. First, the electrolyte solution is introduced into the discharge device through the capillary until the electrolyte liquid level is even with the tip of the capillary. Then the nitric acid of the mercury-containing sample with a pH value of 1 was introduced into the discharge device through the capillary at a flow rate of 0.5 ml / min. The power supply is 700V, and the discharge current is 50mA. The carrier gas is argon, and the flow rate is 400mL / min. The signal is detected by atomic emission, and the signal changes linearly with the sample concentration. figure 2 The flow injection-liquid cathodic discharge mercury vapor generation-atomic emission signal diagram for the determination of 100ng / mL Hg(II) of mercury is...

Embodiment 2

[0025] A titanium rod is selected as the metal anode, and the diameter of the discharge end is 3mm. The cathode material is graphite. The distance between the titanium electrode and the capillary is 4 mm, and the inner diameter of the capillary is 5 mm. First, the electrolyte solution is introduced into the discharge device through the capillary until the electrolyte liquid level is 2mm away from the tip of the capillary. Then, the sulfuric acid of the mercury-containing sample with a pH value of 3 is introduced into the discharge device through the capillary at a flow rate of 10ml / min, the power supply is 2000V, and the discharge current is 150mA. The carrier gas is air with a flow rate of 3000 mL / min. The signal is detected by atomic absorption, and the signal varies linearly with the methylmercury sample concentration.

Embodiment 3

[0027] Platinum is selected as the metal anode, and the diameter of the discharge end is 0.2 mm. The cathode material is stainless steel. The distance between the platinum electrode and the capillary is 2 mm, and the inner diameter of the capillary is 2 mm. First, the electrolyte solution is introduced into the discharge device through the capillary until the electrolyte liquid level is 1mm away from the tip of the capillary, and then the formic acid of the mercury-containing sample with a pH value of 2 is introduced into the discharge device through the capillary at a flow rate of 2ml / min, and the power supply is 200V. The discharge current is 10mA. Helium was used as carrier gas with a flow rate of 30 mL / min. The signal is detected by atomic fluorescence, and the signal varies linearly with the concentration of ethylmercury sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com