Processing technique of profile fiber having functions of moisture absorption and bacteria resistance and products thereof

A special-shaped fiber and processing technology, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of cross-sectional shape difference, affecting the degree of special-shaped fiber, and the antibacterial function of special-shaped fiber needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

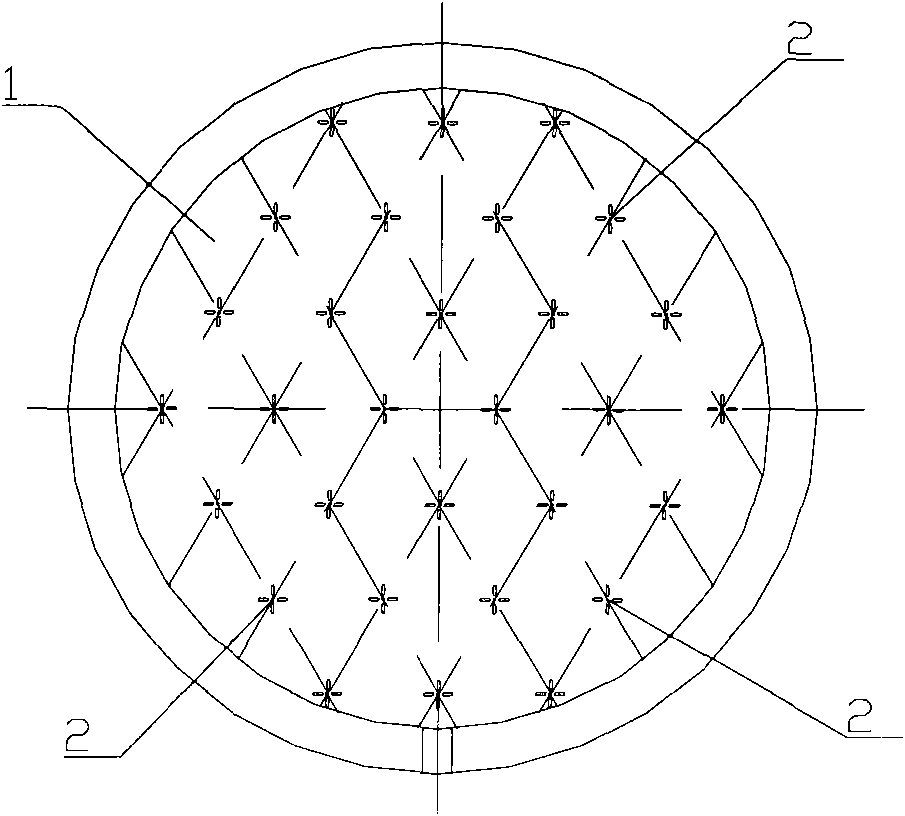

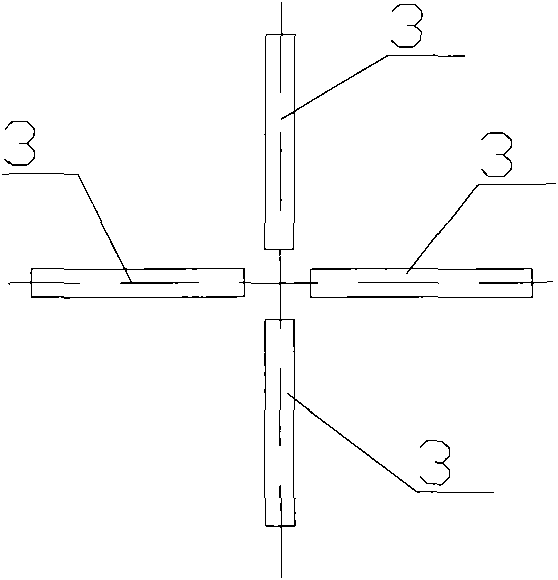

[0047] Such as figure 1 , figure 2 As shown, a processing technology of special-shaped fibers with moisture absorption, perspiration and antibacterial functions, the spinneret used has a plurality of spinneret holes 2 distributed on the plate body 1 to form a spinneret hole array, wherein each spinneret hole 2 includes at least two spray slits 3 that are close together; wherein, on a section perpendicular to the spinning direction, in each of the spinneret holes 2, one side end 5 of each spray slit 3 is close to each other, and the other The side ends 5 are far away from each other; in each of the spinneret holes 2, the spray slits 3 are four and uniformly arranged in the circumferential direction, so that each adjacent spray slit 3 is perpendicular to the spinning direction. perpendicular to each other in section.

[0048] In this embodiment, a processing technology of special-shaped fibers with moisture absorption, perspiration and antibacterial functions includes the fol...

Embodiment 2

[0063] Such as figure 1 , image 3 As shown, a processing technology of special-shaped fibers with moisture absorption, perspiration and antibacterial functions, the spinneret used has a plurality of spinneret holes 2 distributed on the plate body 1 to form a spinneret hole array, wherein each spinneret hole 2 includes at least two spray slits 3 that are close together; wherein, on a section perpendicular to the spinning direction, in each of the spinneret holes 2, one side end 5 of each spray slit 3 is close to each other, and the other The side ends 5 are far away from each other; in each of the spinneret holes 2, the spray slits 3 are four and uniformly arranged in the circumferential direction, so that each adjacent spray slit 3 is perpendicular to the spinning direction. perpendicular to each other in section.

[0064] In this embodiment, a processing technology of special-shaped fibers with moisture absorption, perspiration and antibacterial functions includes the foll...

Embodiment 3

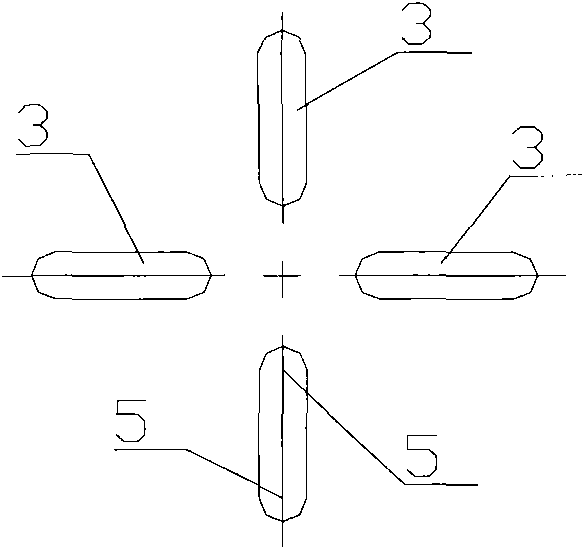

[0079] Such as figure 1 , Figure 4 As shown, a processing technology of special-shaped fibers with moisture absorption, perspiration and antibacterial functions, the spinneret used has a plurality of spinneret holes 2 distributed on the plate body 1 to form a spinneret hole array, wherein each spinneret hole 2 includes at least two spray slits 3 that are close together; wherein, on a section perpendicular to the spinning direction, in each of the spinneret holes 2, one side end 5 of each spray slit 3 is close to each other, and the other The side ends 5 are far away from each other; in each of the spinneret holes 2, the spray slits 3 are four and uniformly arranged in the circumferential direction, so that each adjacent spray slit 3 is perpendicular to the spinning direction. The sections are perpendicular to each other, and the center of each spray slit 3 is provided with a central spray hole 4 .

[0080] In this embodiment, a processing technology of special-shaped fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com