Concrete antifreezer and preparation method thereof

A technology of concrete and antifreeze, which is applied in the field of concrete antifreeze, which can solve problems such as failure of normal pumping construction and degradation of concrete construction performance, and achieve the effects of improving the antifreeze effect, reducing the water-cement ratio, and increasing the amount of air-entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

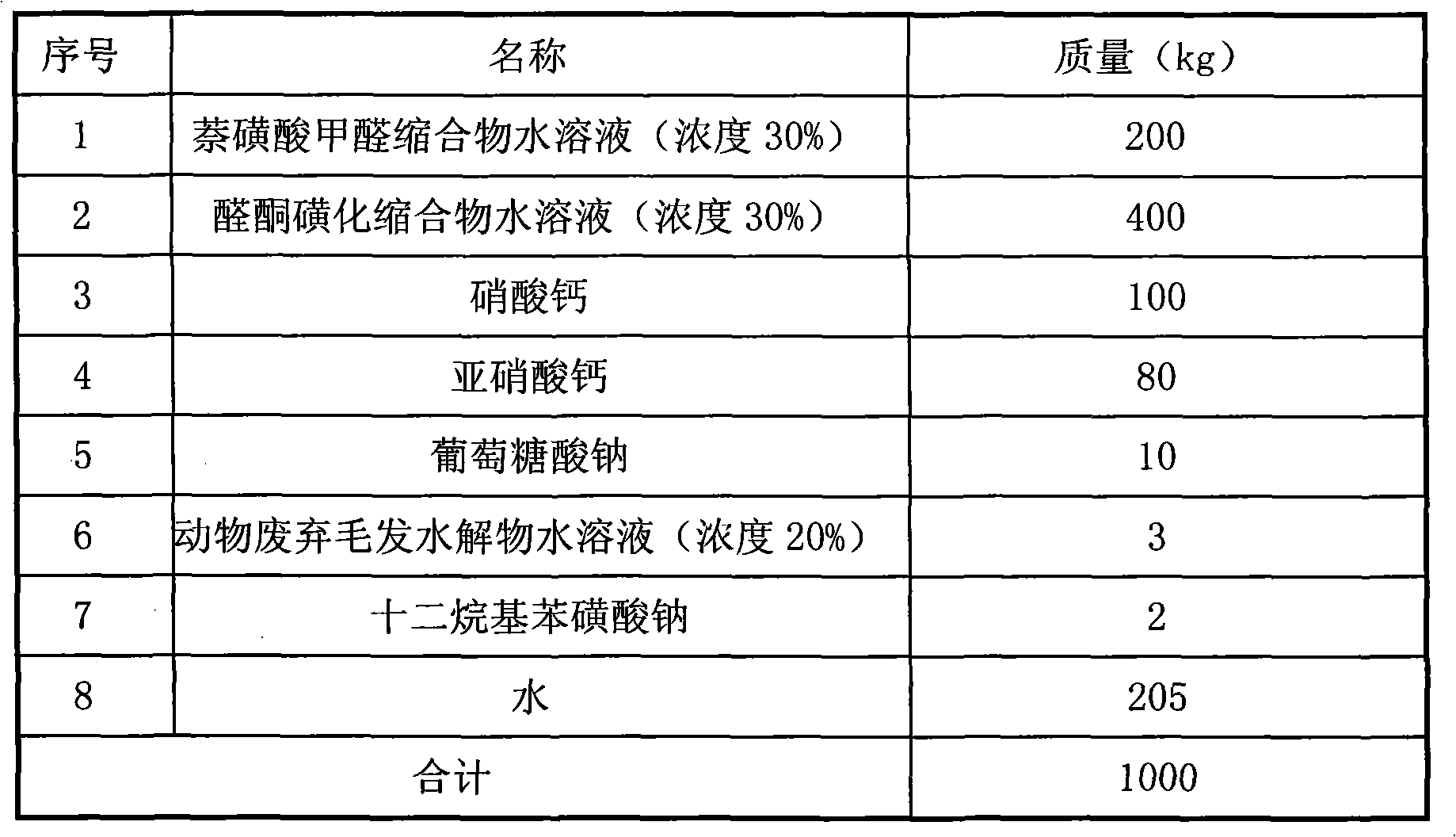

[0012] Prepare materials according to the following mass ratio

[0013]

[0014] First add naphthalenesulfonic acid formaldehyde condensate and aldehyde ketone sulfonated condensate, adjust the temperature to 30°C, stir for ten minutes, add sodium gluconate, continue stirring for 15 minutes, and finally add the air-entraining agent prepared according to the formula, calcium nitrate and Calcium nitrite, stir for 30 minutes, add water to adjust the concentration, stir for another 15 minutes, and discharge.

Embodiment 2

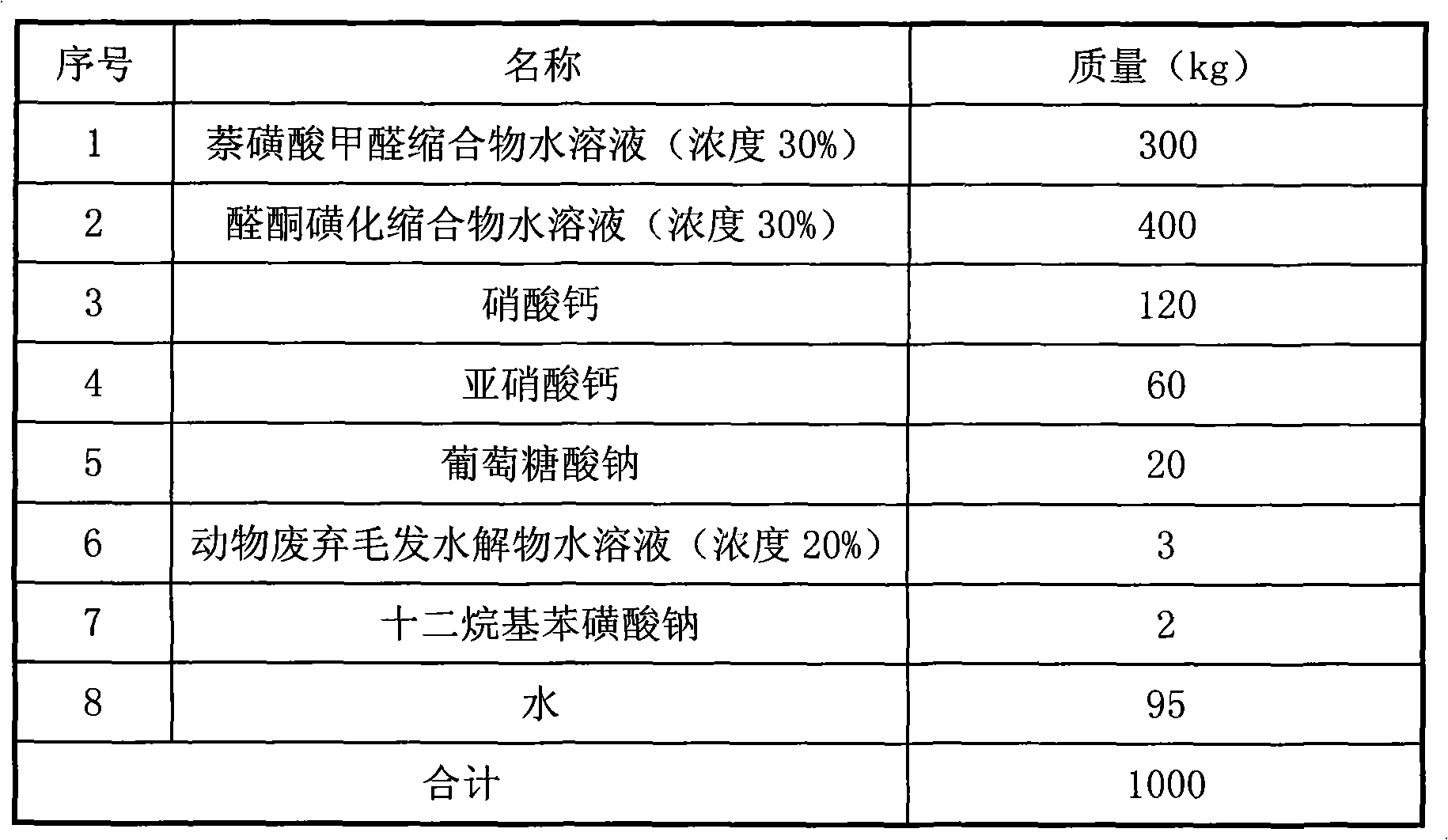

[0016] Prepare materials according to the following mass ratio

[0017]

[0018] First add naphthalenesulfonic acid formaldehyde condensate and aldehyde ketone sulfonated condensate, adjust the temperature to 30°C, stir for ten minutes, add sodium gluconate, continue stirring for 15 minutes, and finally add the air-entraining agent prepared according to the formula, calcium nitrate and Calcium nitrite, stir for 30 minutes, add water to adjust the concentration, stir for another 15 minutes, and discharge.

Embodiment 3

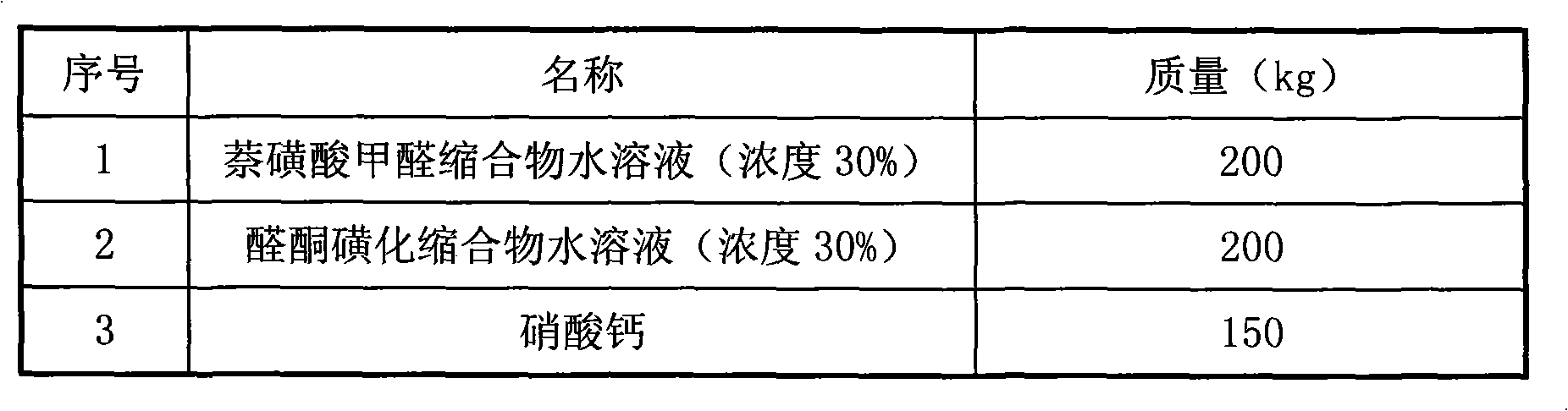

[0020] Prepare materials according to the following mass ratio

[0021]

[0022]

[0023] First add naphthalenesulfonic acid formaldehyde condensate and aldehyde ketone sulfonated condensate, adjust the temperature to 30°C, stir for ten minutes, add sodium gluconate, continue stirring for 15 minutes, and finally add the air-entraining agent prepared according to the formula, calcium nitrate and Calcium nitrite, stir for 30 minutes, add water to adjust the concentration, stir for another 15 minutes, and discharge.

[0024] After testing, the product performance in the embodiment of the present invention 1 is as follows:

[0025] Table 1: Properties of concrete mixture and hardened concrete

[0026]

[0027]

[0028] Note: The dosage is 4% (reduced solid content) Cement: benchmark cement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com