A kind of cement concrete with high slump retention and high strength and preparation method thereof

A cement concrete and high-strength technology, applied in the field of building materials, can solve problems such as the influence of concrete setting time, unfavorable concrete water-cement ratio, and damage to the good gradation of sand, and achieve the effect of promoting dust suppression, improving compressive strength, and reducing slump The effect of drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

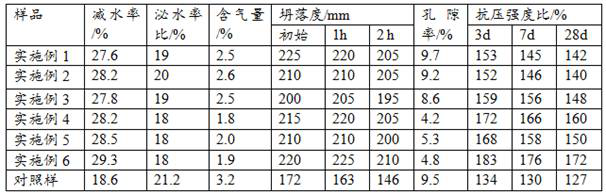

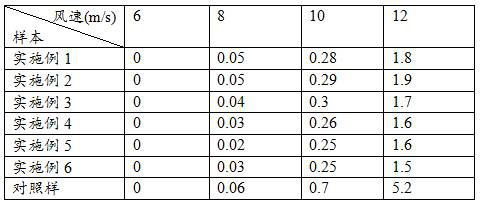

Examples

Embodiment 1

[0025] A high-slump high-strength cement concrete, comprising 200 parts of cement, 700 parts of medium sand, 600 parts of gravel, 60 parts of admixture, 4 parts of admixture and 140 parts of water by mass; the admixture includes 1 part of anti-mud agent, 3 parts of polycarboxylate superplasticizer and 1 part of calcium chloride.

[0026] The admixture is coal ash.

[0027] The anti-mud agent is composed of fluorocarbon surfactant, calcium stearate and hexametaphosphoric acid, and the mass ratio is 3:1:2.

[0028] The polycarboxylate superplasticizer is prepared from polycarboxylate water-reducing mother liquor, polycarboxylate slump-preserving mother liquor, sodium lauryl sulfate, glucose sulfonate and water, with a mass ratio of 350:80 :5:1:500.

Embodiment 2

[0030] A high-slump high-strength cement concrete, comprising 500 parts of cement, 1100 parts of medium sand, 1100 parts of gravel, 150 parts of admixture, 10 parts of admixture and 200 parts of water by mass; the admixture includes 2 parts of anti-mud agent, 6 parts of polycarboxylate superplasticizer, 2 parts of calcium chloride.

[0031] The admixture is coal ash.

[0032] The particle size of the gravel is 20-30mm.

[0033] The anti-mud agent is composed of fluorocarbon surfactant, calcium stearate and hexametaphosphoric acid, and the mass ratio is 3:1:2.

[0034] The polycarboxylate superplasticizer is prepared from polycarboxylate water-reducing mother liquor, polycarboxylate slump-preserving mother liquor, sodium lauryl sulfate, glucose sulfonate and water, with a mass ratio of 350:80 :5:1:500.

Embodiment 3

[0036] A high-slump high-strength cement concrete, comprising 240 parts of cement, 1000 parts of medium sand, 940 parts of gravel, 70 parts of admixture, 5 parts of admixture and 155 parts of water by mass; the admixture includes 1-2 parts of anti-mud agent, 3-6 parts of polycarboxylate superplasticizer, 1-2 parts of calcium chloride.

[0037] The admixture is coal ash.

[0038] The particle size of the gravel is 20-30mm.

[0039] The anti-mud agent is composed of fluorocarbon surfactant, calcium stearate and hexametaphosphoric acid, and the mass ratio is 3:1:2.

[0040] The polycarboxylate superplasticizer is prepared from polycarboxylate water-reducing mother liquor, polycarboxylate slump-preserving mother liquor, sodium lauryl sulfate, glucose sulfonate and water, with a mass ratio of 350:80 :5:1:500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com