Baffling contact precipitation integral anaerobic reactor

An anaerobic reactor and reaction chamber technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. and other problems, to achieve the effect of good effluent quality, stable operation and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the drawings:

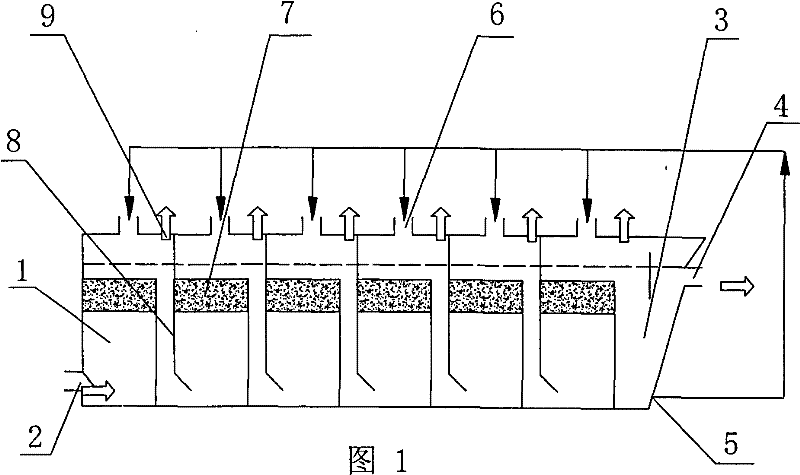

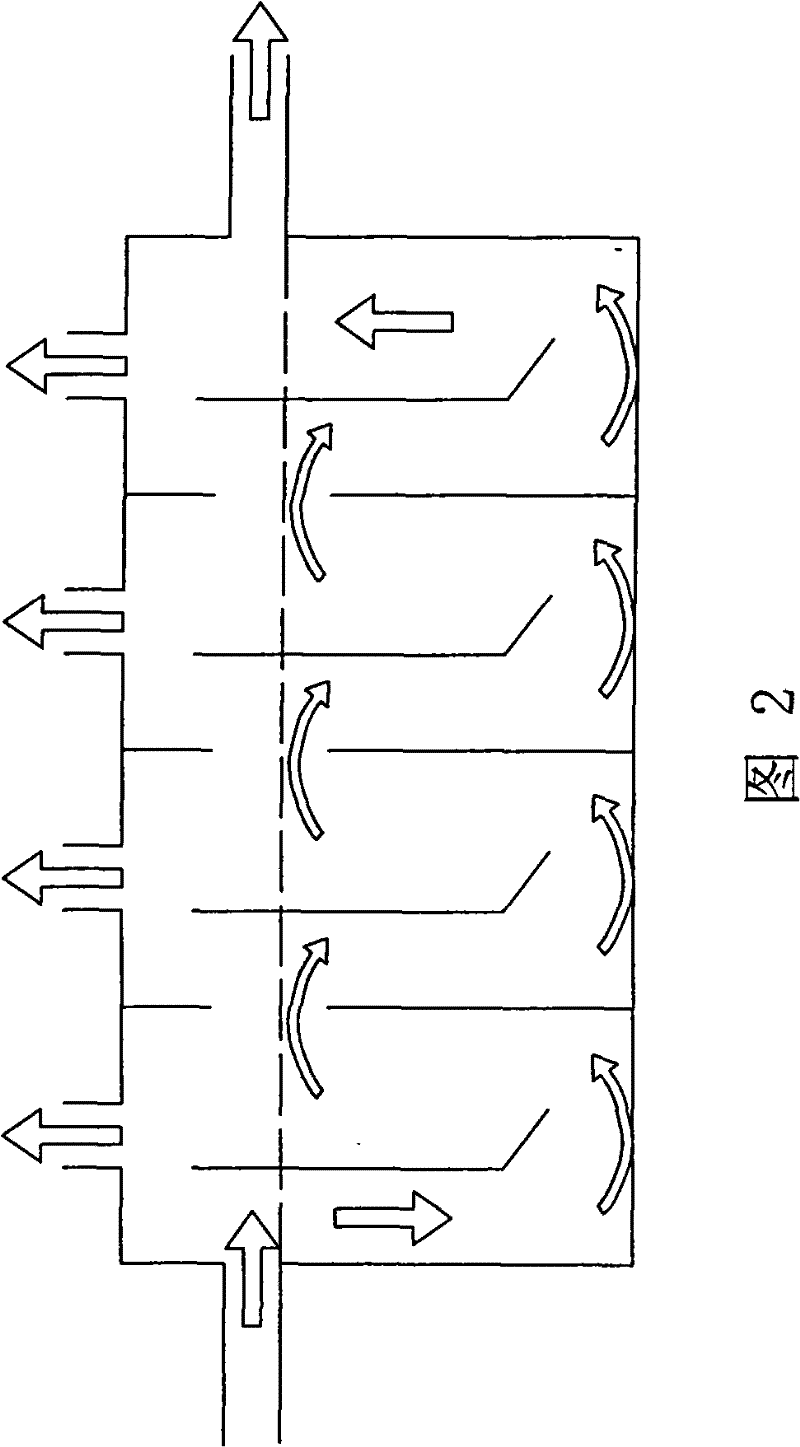

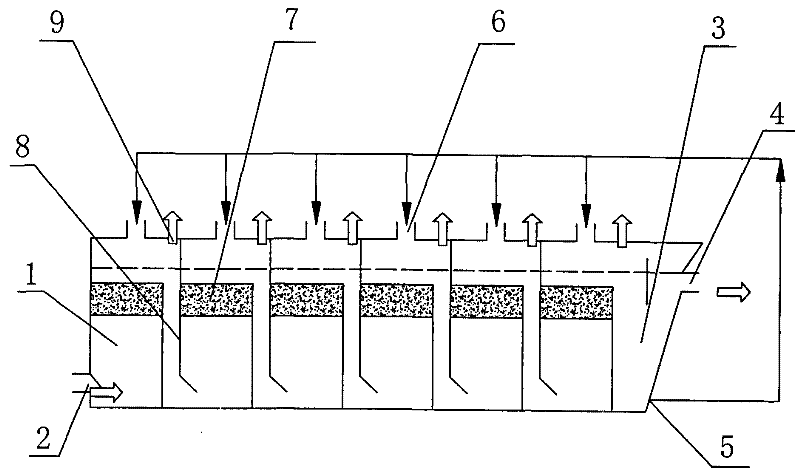

[0024] Such as figure 1 As shown, the present invention is composed of a plurality of reaction chambers 1 connected in series. A water inlet 2 is provided at the lower end of the reaction chamber 1 located at the far left end, and the reaction chamber 1 located at the far right end is connected with a solid-liquid separator 3. Connected. The solid-liquid separator 3 is a non-distance-shaped container with a water outlet 4 on its upper part, and the separated sewage is discharged from the water outlet 4. A sludge return outlet 5 is provided at the bottom of the solid-liquid separator 3, which is connected to the sludge return inlet 6 at the top of each reaction chamber 1, and the separated and treated sludge in the solid-liquid separator 3 is returned from the sludge return outlet 5 Return to the top of each reaction chamber 1, enter the reaction chamber 1 from the sludge return inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com