Gum cover for vulcanizing driving belt

A technology of transmission belts and rubber sleeves, applied in applications, belts, household appliances, etc., can solve the problems of poor sealing effect and failure to achieve sealing effect, reduce shrinkage deformation, increase the number of times of use, and reduce air leakage from the belt cylinder The effect of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

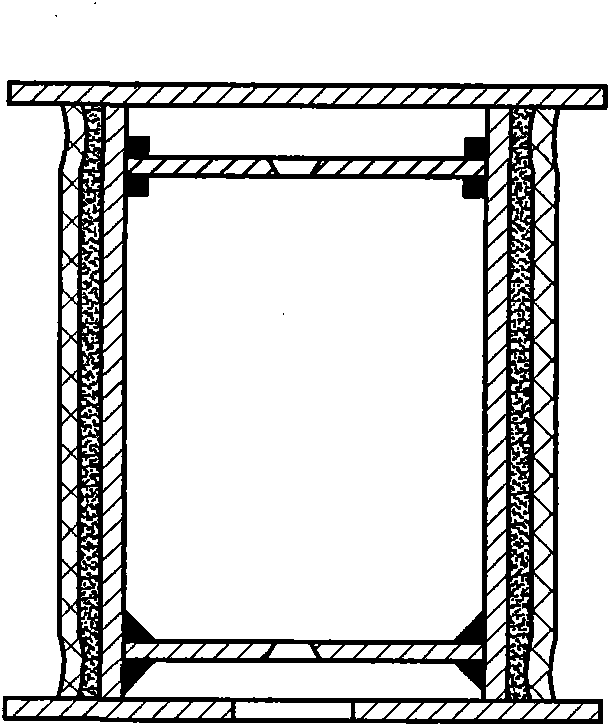

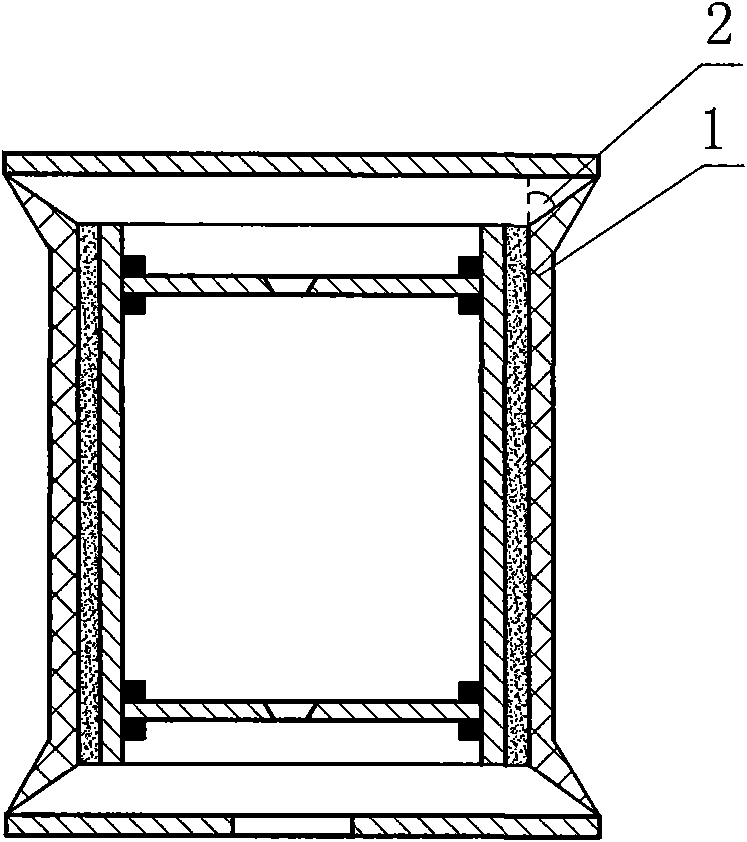

[0014] Please refer to the figure 1 .

[0015] The rubber sleeve for vulcanization of the drive belt is barrel-shaped, with open upper and lower ends, and is characterized in that a ring of sealing lips 1 is provided on each of the two ends.

[0016] The sealing lip forms an acute angle 2 with the inner wall of the rubber sleeve.

[0017] The length of the sealing lips at both ends of the barrel-shaped rubber sleeve is greater than the thickness of the rubber sleeve.

[0018] The section of the sealing lip at both ends of the barrel-shaped rubber sleeve gradually becomes thinner from thicker.

[0019] The section of the sealing lip is triangular.

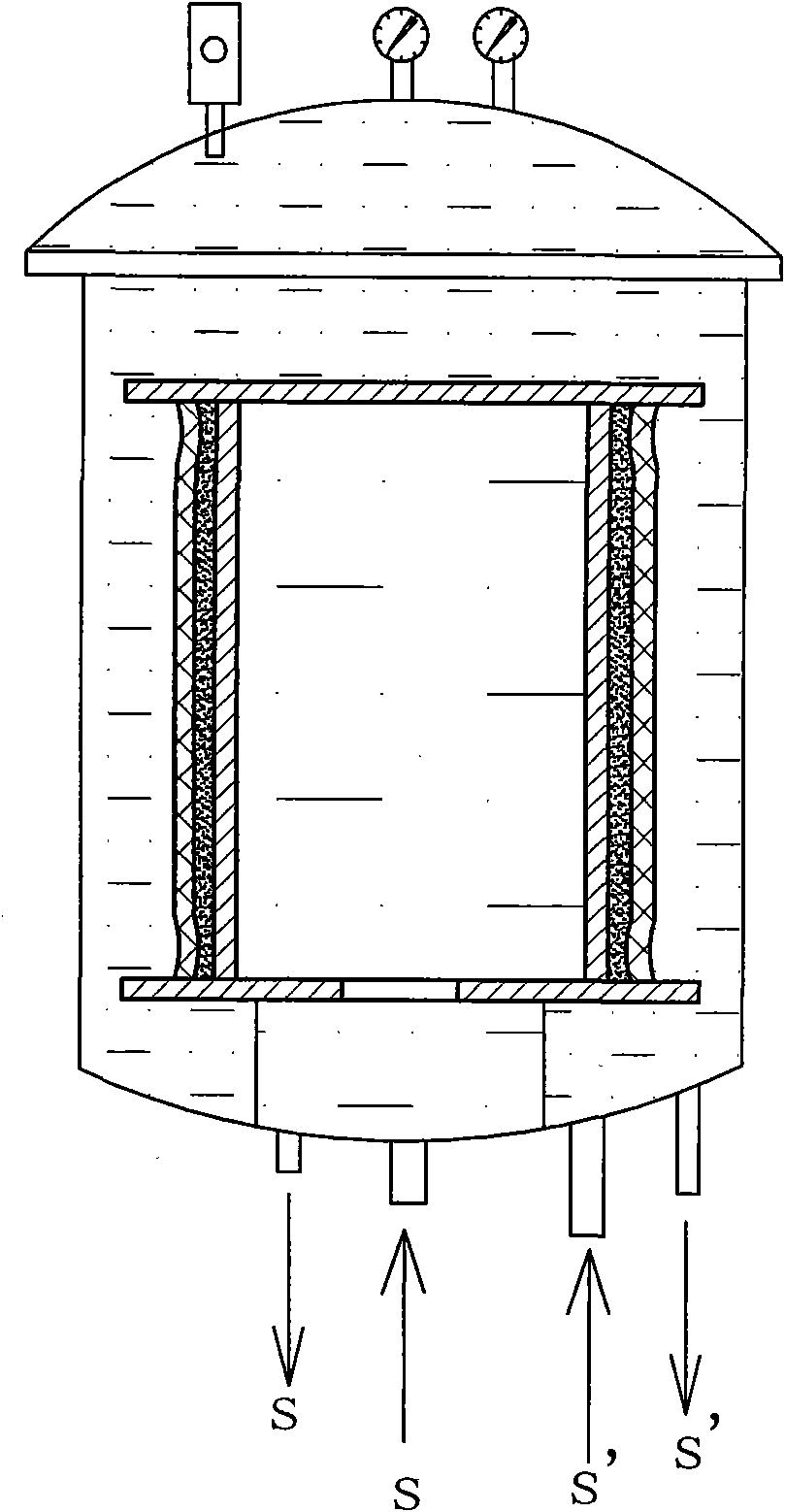

[0020] The working state of the present invention is such that the rubber layer that is about to become a transmission belt is covered outside the barrel-shaped mold, and the rubber sleeve of the present invention is wrapped outside the rubber layer. After the three are wrapped, they are sent into the pressure vessel and covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com