Functional system module combinational method on production lines of daily chemical products

A technology of system modules and combination methods, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problems of investment cost reduction, direct cost reduction, etc., to improve utilization rate, The effect of reducing the loss rate of raw materials and reducing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

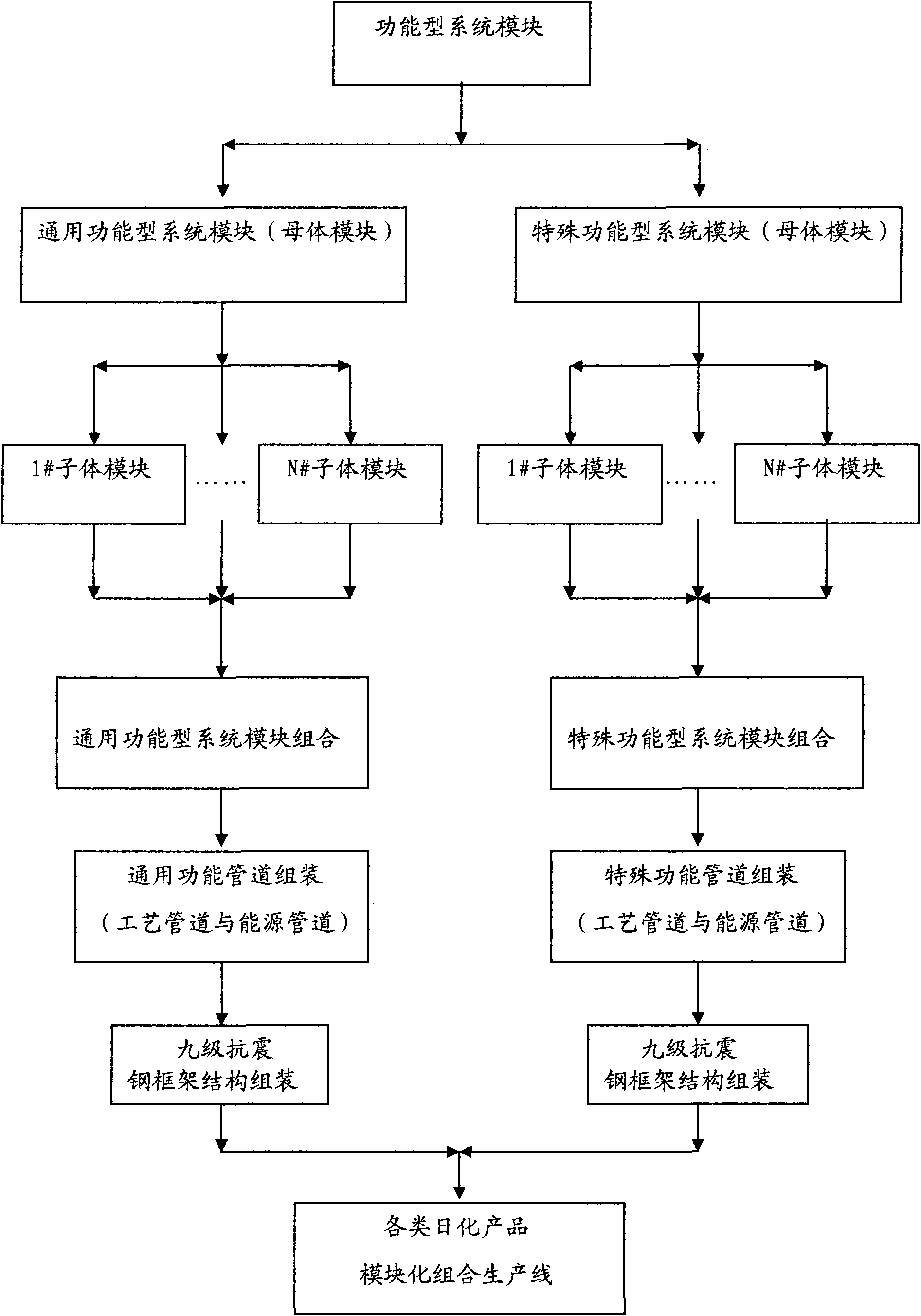

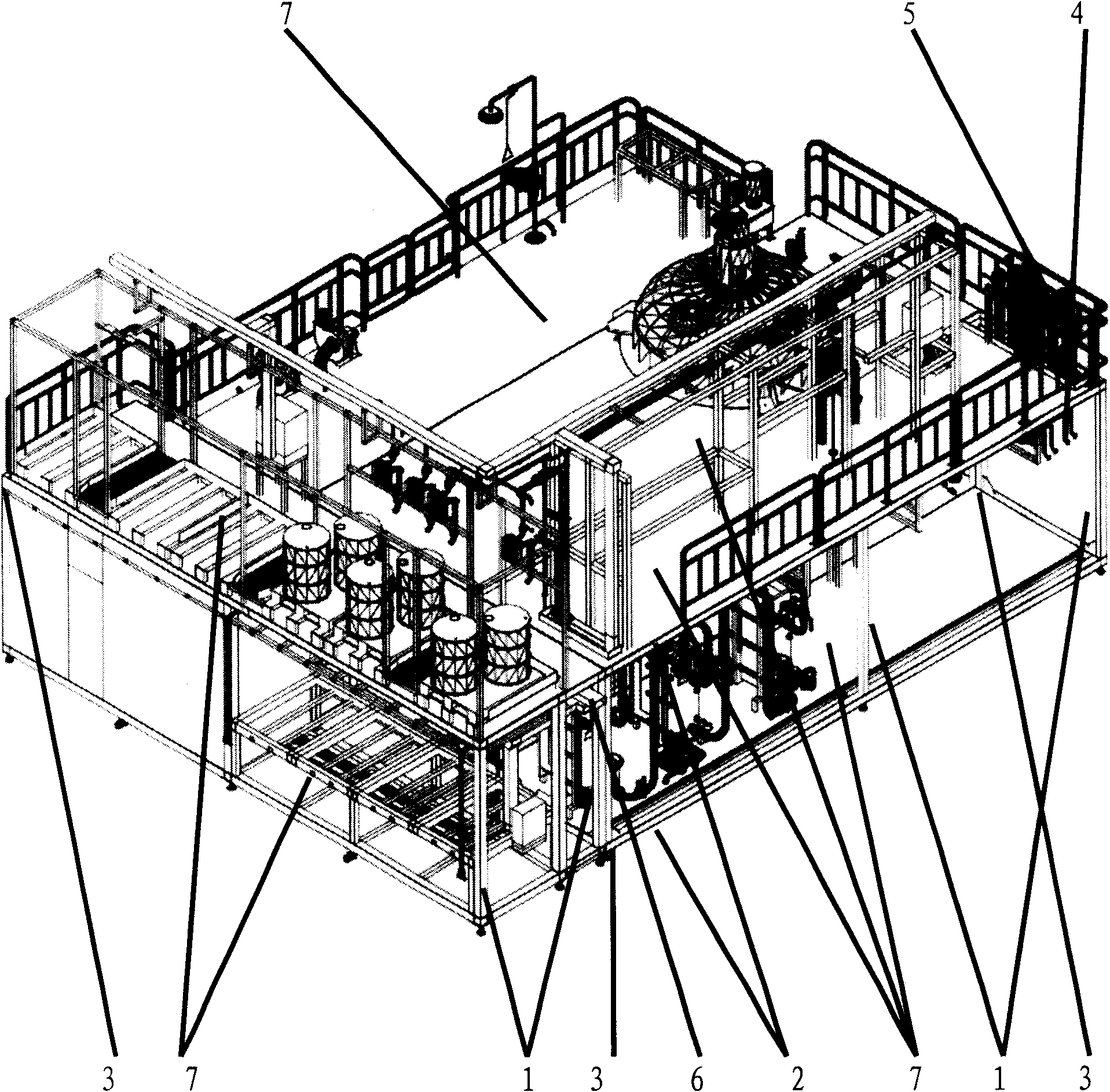

[0048] A method for combining functional system modules on a production line of daily chemical products. The main technical solutions include: (1). Design and manufacture various system modules with different independent functions; (2). According to the production process requirements of different daily chemical products , to combine, assemble and connect various system modules with different independent functions to form a multifunctional daily chemical product production line.

[0049] Among them, option (1) also includes the following options:

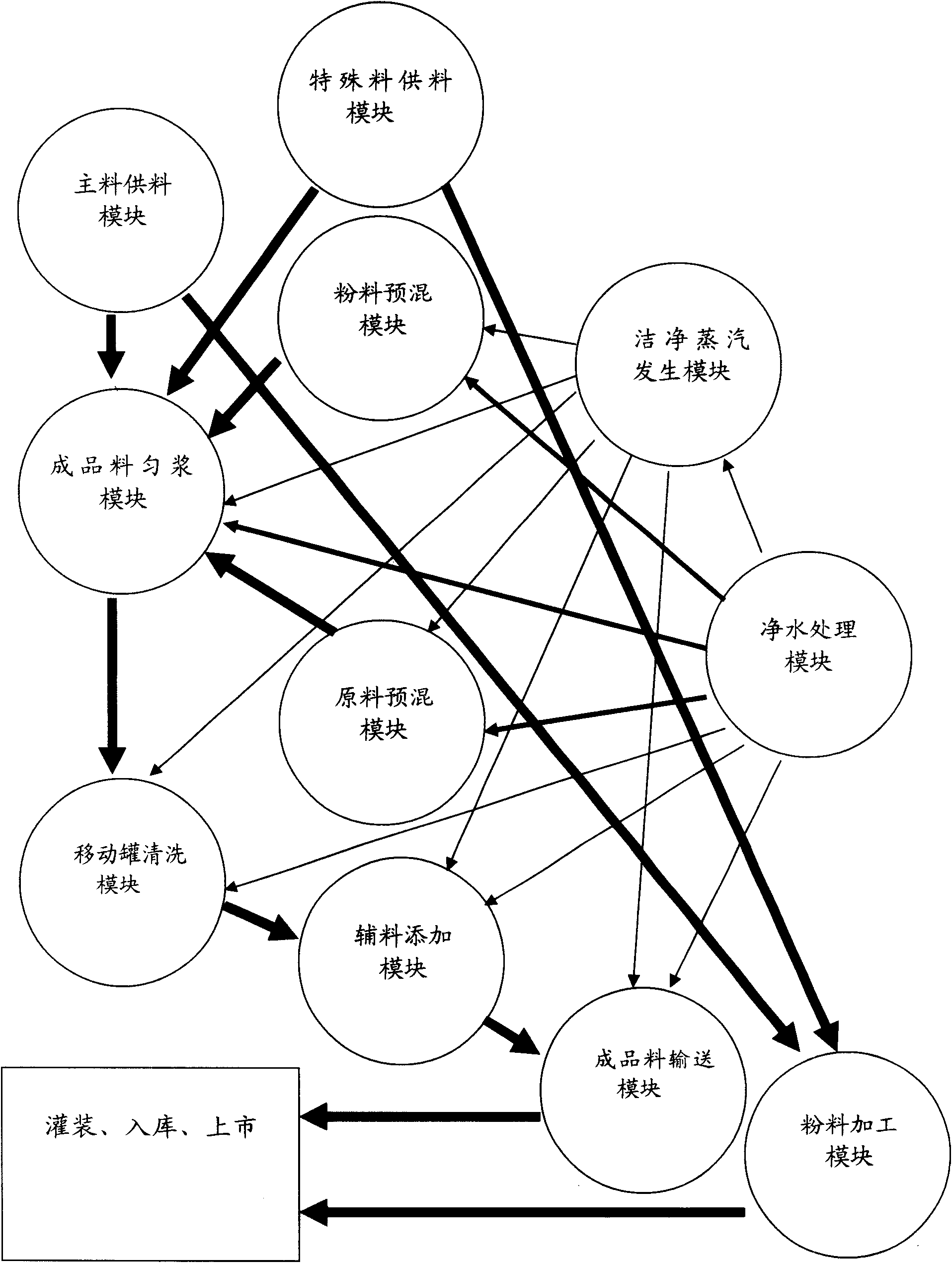

[0050] A. Design and manufacture various system modules with independent functions according to the process requirements, which are mainly divided into two types, namely: 1. General functional system modules: finished material homogenization module, raw material premixing module, powder premixing module Module, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com