Protective helmet

A component and lining technology, which is applied in the field of protective helmets, can solve the problems of reducing the protective effect of protective helmets, disadvantages, the discharge effect of lining components and the difficulty of controlling internal pressure, etc., and achieve a good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

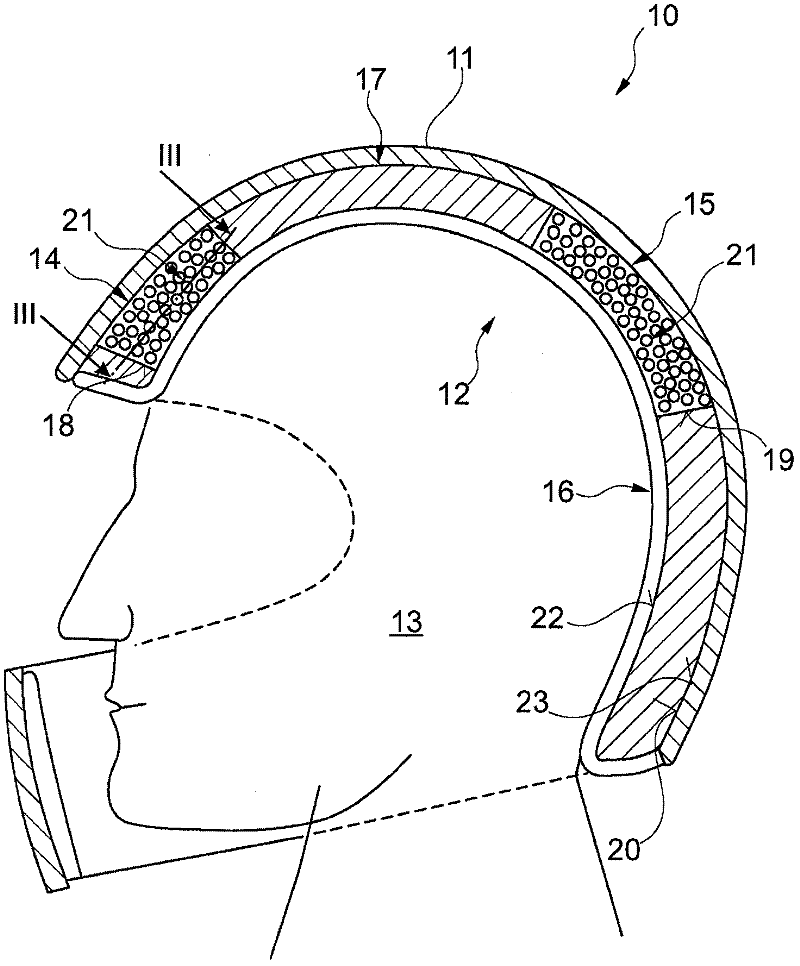

[0025] figure 1 A protective helmet 10 is shown, which is shown in section for better illustration, with an outer shell designed as an outer shell 11 and a lining element structure 12 accommodated therein. The protective helmet 10 shown here placed on the head 13 of the helmet user is a full-face protective helmet for motorcycle riders. This protective helmet can also be designed as a nozzle helmet or a half-face helmet. Furthermore, especially with respect to the configuration of the housing 11 , lighter embodiments are conceivable, which can be used, for example, for different winter sports or for cyclists.

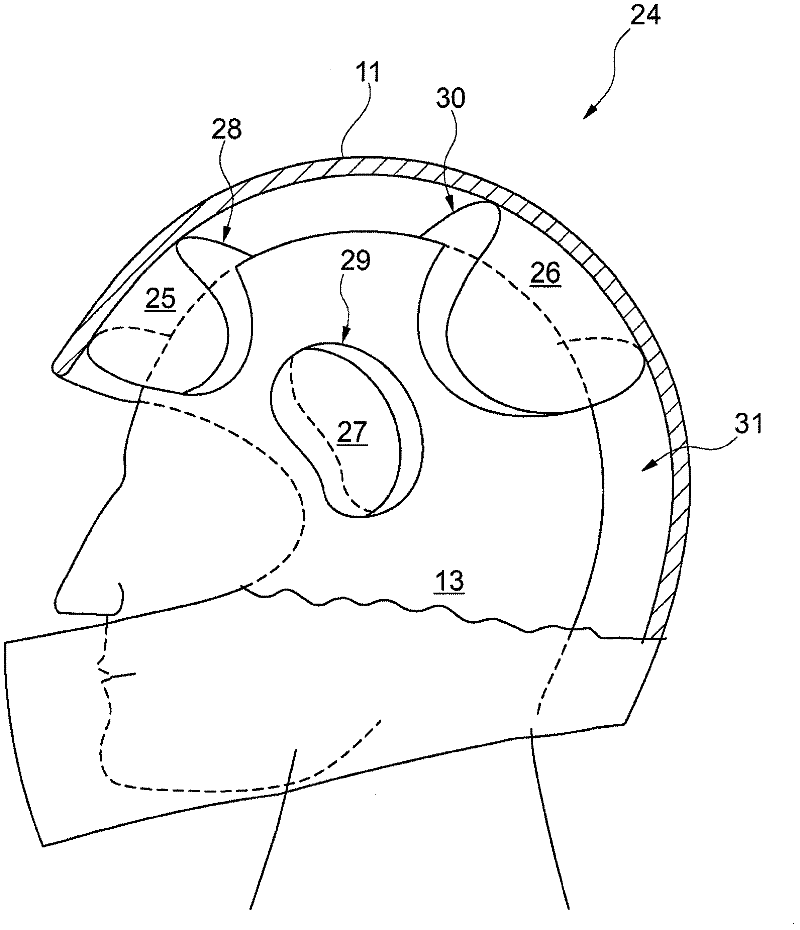

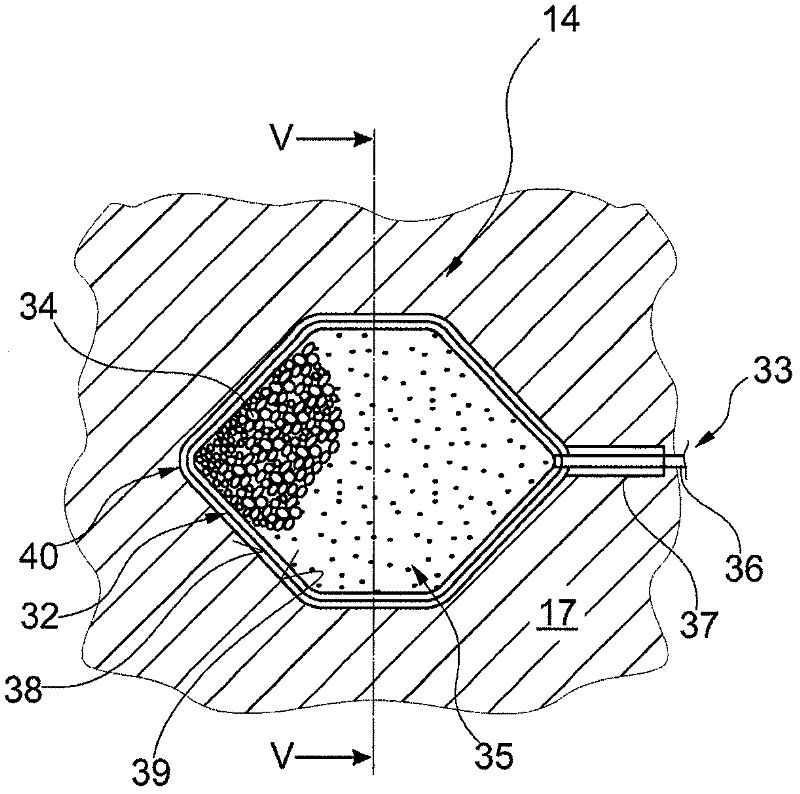

[0026] Regardless of the design of the housing 11, in any case a lining element structure 12 is provided, which in the exemplary embodiment consists of spacer elements 14 and 15, packing elements 16 and a lining shell surrounding the spacer elements. Layer elements 17 are formed. The liner shell element 17 here substantially covers the inner surface 20 of the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com