Hydraulic turbogenerator short circuit drying process

A hydro-generator and generator technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of hydro-generator windings damp, easily damaged insulating layer, long maintenance time, etc., and achieve loss of electrical energy. Small, low cost, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

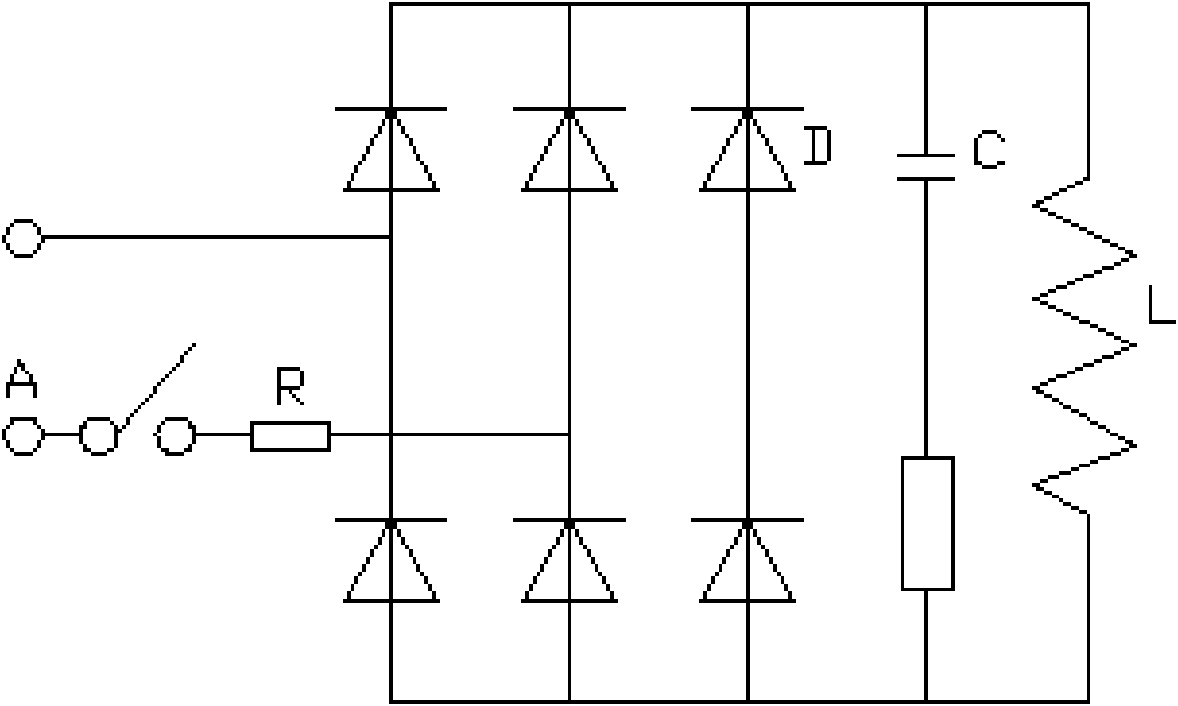

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0015] This embodiment takes the double-winding excitation wiring method as an example to illustrate. The double-winding includes reactance shunt and third harmonic excitation. Since the primary and secondary windings are equivalent to the primary and secondary coils of the transformer, after the main winding is short-circuited, the secondary winding cannot There is voltage again, but its rectification part can still be used, but the voltage of the power grid can be used as the excitation power supply after the step-down and current limiting. We use high-power heating wires to reduce voltage and limit current, and use the number of heating wires connected in parallel to adjust the excitation in stages. According to Ohm's law, the more heating wires connected in parallel, the smaller the impedance, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com