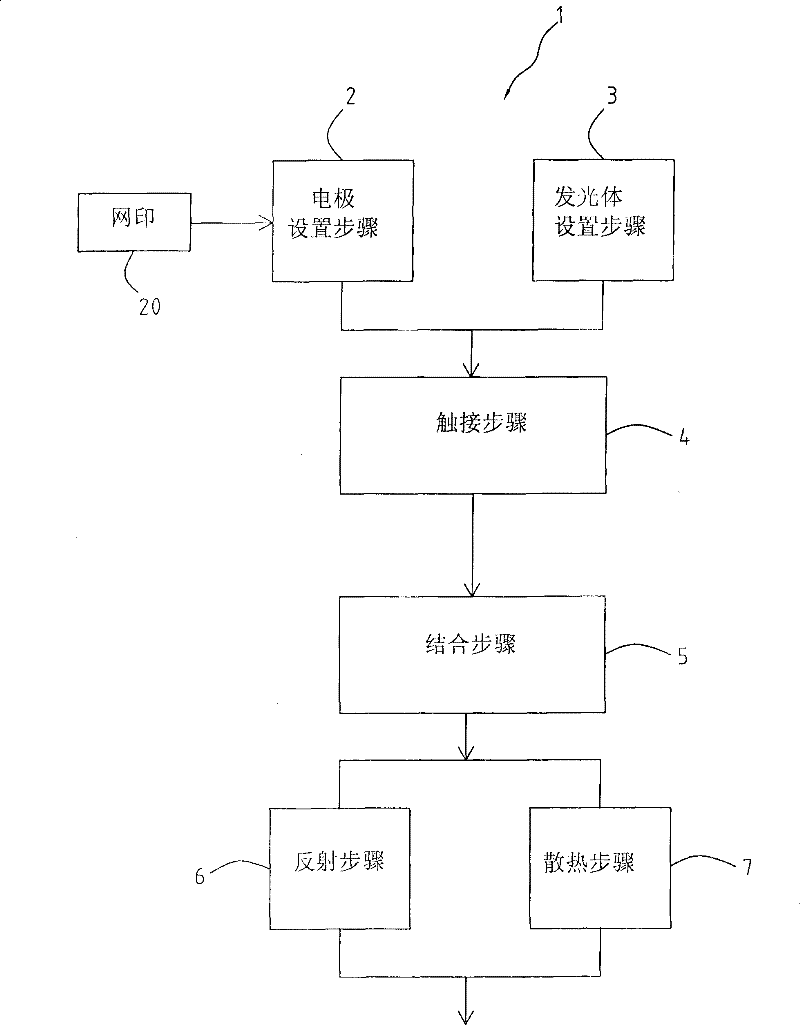

Packaging process of light-emitting elements

A light-emitting element and packaging process technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, and electric solid-state devices, to achieve the effects of improving luminous efficiency, increasing production capacity, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

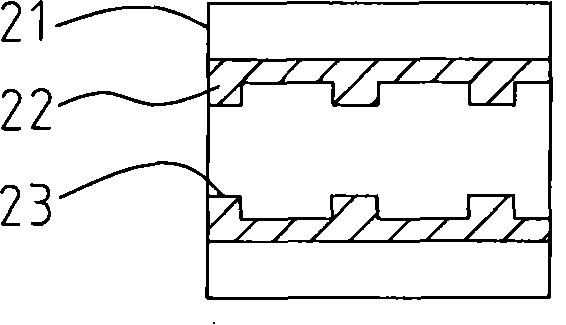

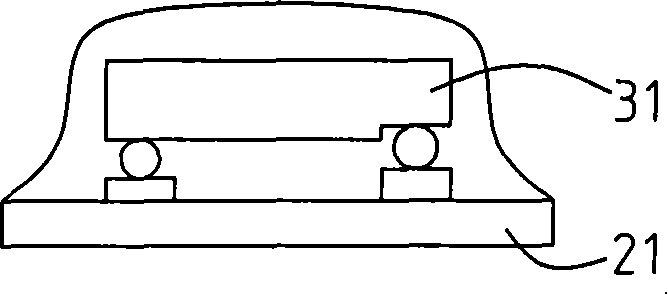

[0023] refer to Figure 2A -F is the first embodiment of the packaging process of the light-emitting element of the present invention. In this embodiment, a positive electrode 22 and a negative electrode 23 are defined by etching on a carrier 21, so that the carrier 21 is formed with a positive electrode and a negative electrode. electrode slides (i.e. step 2 for electrode setup, see Figure 2A and Figure 2B ; As previously mentioned, the material of the positive electrode and the negative electrode can also be directly selected to directly define the electrode, or the electrode carrier with the positive electrode and the negative electrode can be selected without going through the etching process), in addition, Select a surface-mounted (SMD) light-emitting diode chip 31 with a positive electrode 32 and a negative electrode 33 on it (that is, the step 3 for setting the light emitter), and then use ball grid array packaging technology (BGA) to define a positive electrode 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com