Energy-saving and modification method for heat pump distillation and device thereof

A technology of heat pump rectification and energy-saving transformation, which is applied in the direction of fractionation, etc., and can solve problems such as inability to adjust or narrow adjustment range, energy-saving transformation of old distillation towers, heat mismatch between tower top and bottom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

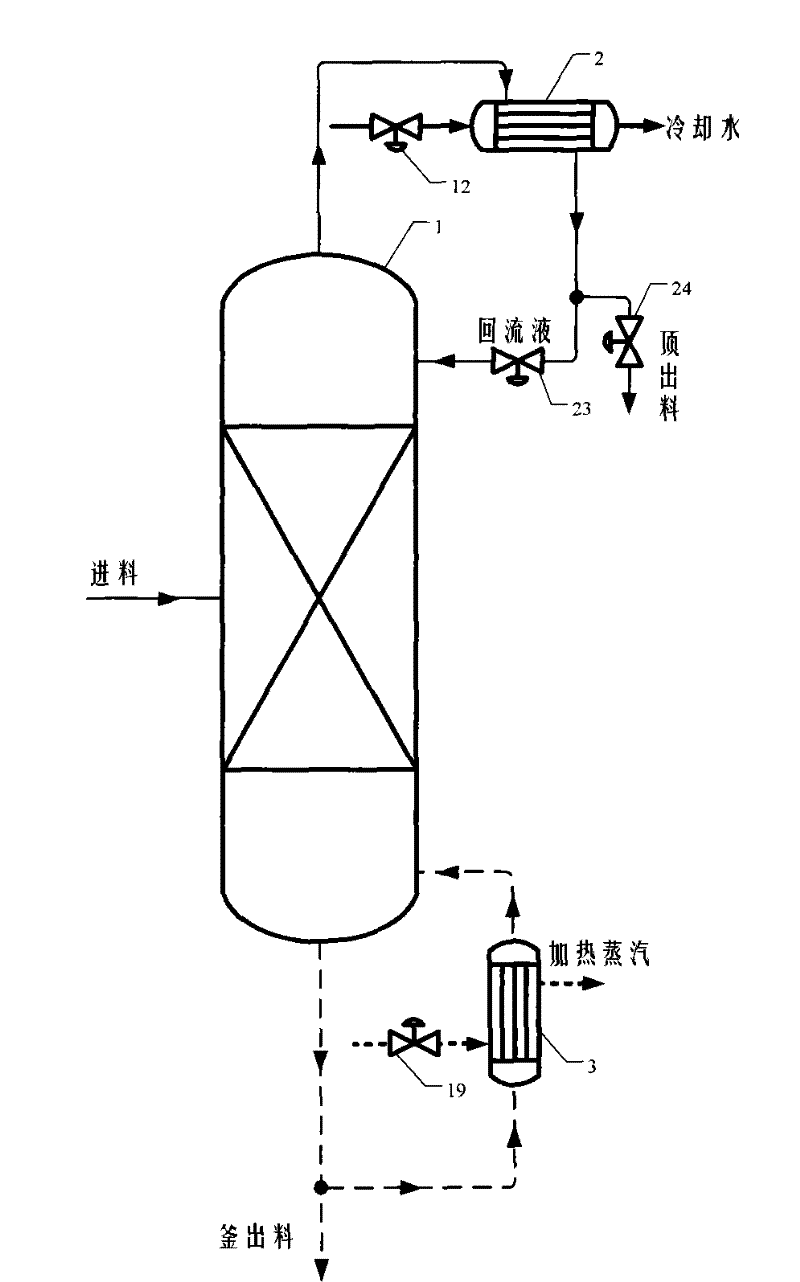

[0025] figure 1 It is a schematic diagram of the structure and process flow of a common normal rectification device. The rectification device consists of a rectification tower 1, a condenser 2, a main reboiler 3, a flow regulating valve 12, a flow regulating valve 19, a flow regulating valve 23 and A flow regulating valve 24 constitutes. The condensation heat of steam at the top of rectification tower 1 is all taken away by the external cooling water, and all the evaporation heat of the liquid at the bottom of the tower is provided by external heating steam. Such as figure 1 As shown, the vertical position of the condenser 2 is higher than the reflux hole of the rectification tower 1, and the reflux liquid and the top discharge flow to the corresponding inlets by gravity, and the flow is regulated by the reflux liquid regulating valve 23 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com