A reversible crusher

A crusher and crushing chamber technology, which is applied in the field of crushers in the field of crushing technology, can solve the problems of not finding the primary screening and filtering scheme for materials, achieve optimal screening processing effects, save floor space, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

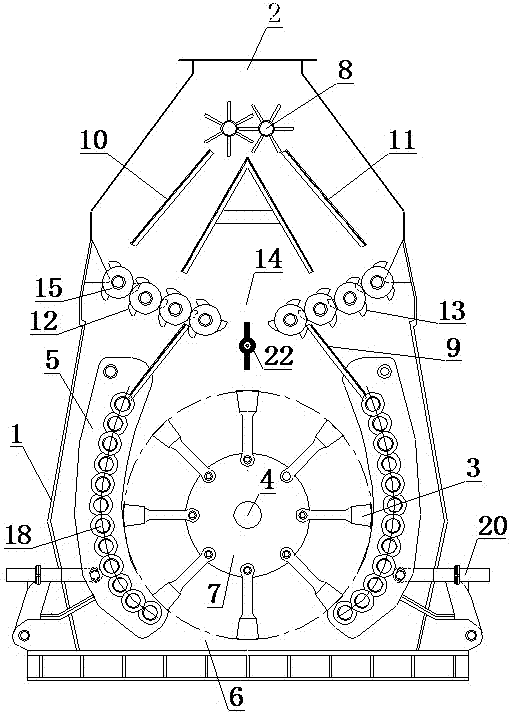

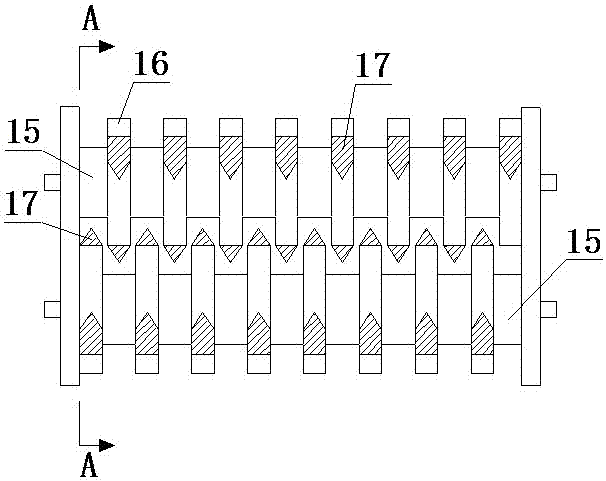

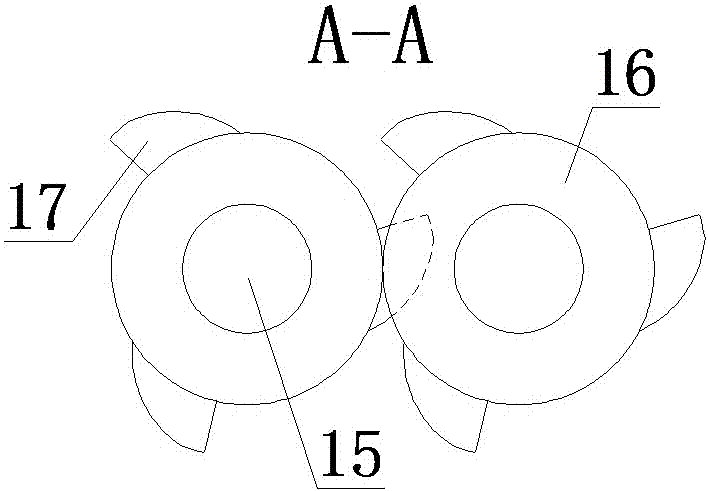

[0029] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a reversible crusher of the present invention includes a housing 1, a feed port 2, a crushing bin provided with a crushing device, and a material distribution device arranged between the feed port 2 and the crushing bin from top to bottom. 8, a material guide plate, a screen distributor and a screen baffle 9, and a discharge port 6 is provided below the crushing bin.

[0030] The crushing device includes a main rotor 4 with a plurality of hammerheads 3 installed in the middle of the crushing bin, and impact frames 5 with crushing counterattack devices installed on both sides of the crushing bin. The hammer head 3 is installed on the main rotor 4 through the hammer plate 7, and the hammer head 3 is evenly distributed and hinged on the hammer plate 7. The hammer head 3 can be a conventional ring hammer or a square hammer as required. The hammer plate 7 fixed on the main rotor 4. The crushing counterattack...

Embodiment 2

[0034] Such as figure 1 , Figure 5 with Image 6 As shown, the present invention is used for energy-saving transformation of traditional reversible crushers. Will figure 1 The distributor 8, material guide plate, sieve distributor and sieve baffle 9 and the corresponding shells in the Figure 5 Above the crushing feed inlet of the existing crusher shown above and fixed by bolts, it can be transformed into Image 6 Shown is the reversible crusher of this embodiment. Before installation, it is necessary to slightly modify the shell on the top of the existing reversible crusher to facilitate installation and coordination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com