Toner and method of preparing the same

A technology of toner and toner image, applied in the field of toner with a core-shell structure, can solve the problems of reverse charging of toner, decrease of image definition, and deterioration of particle size distribution, and achieve low initial Effects of image density, improved charging rate, and wide melting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

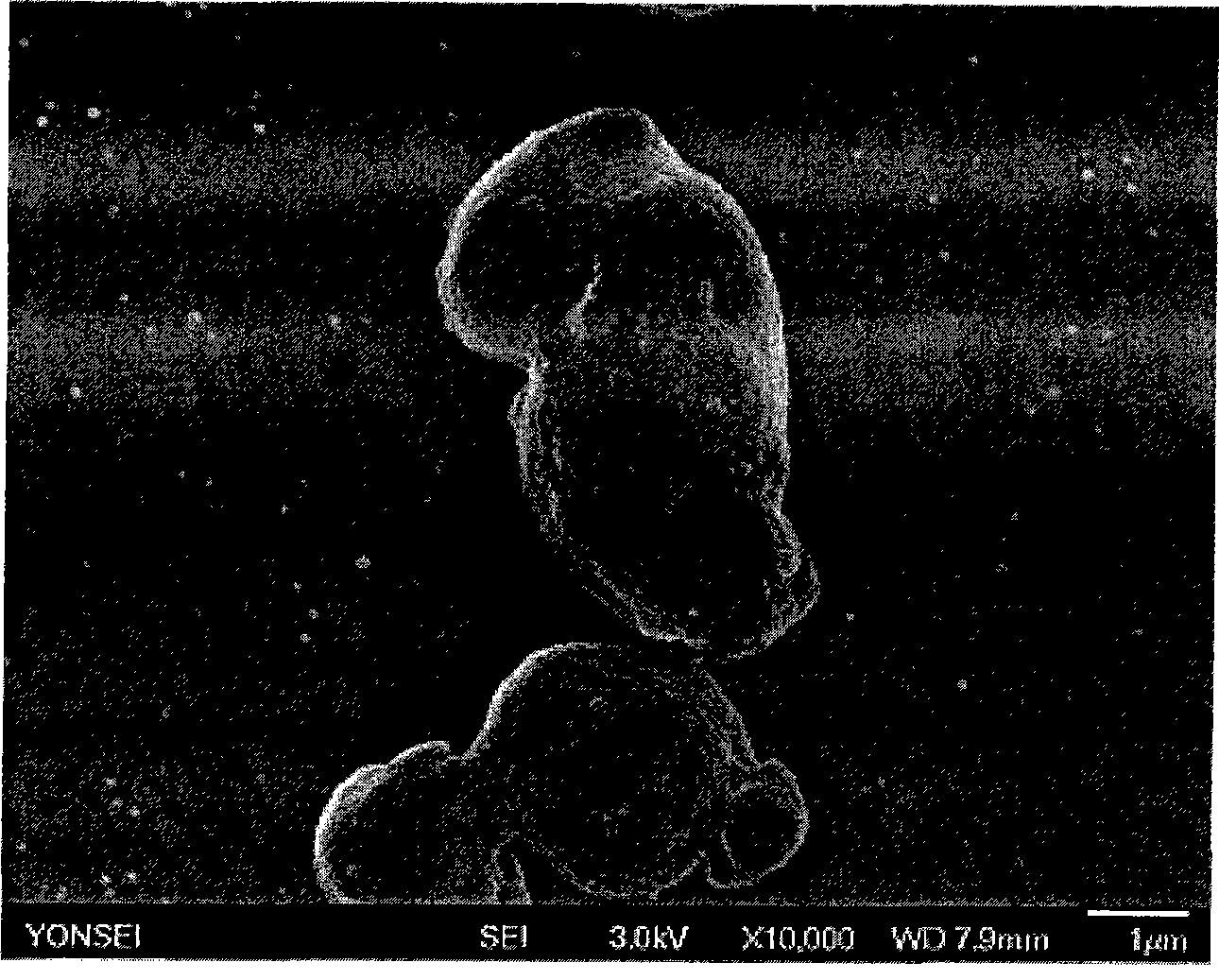

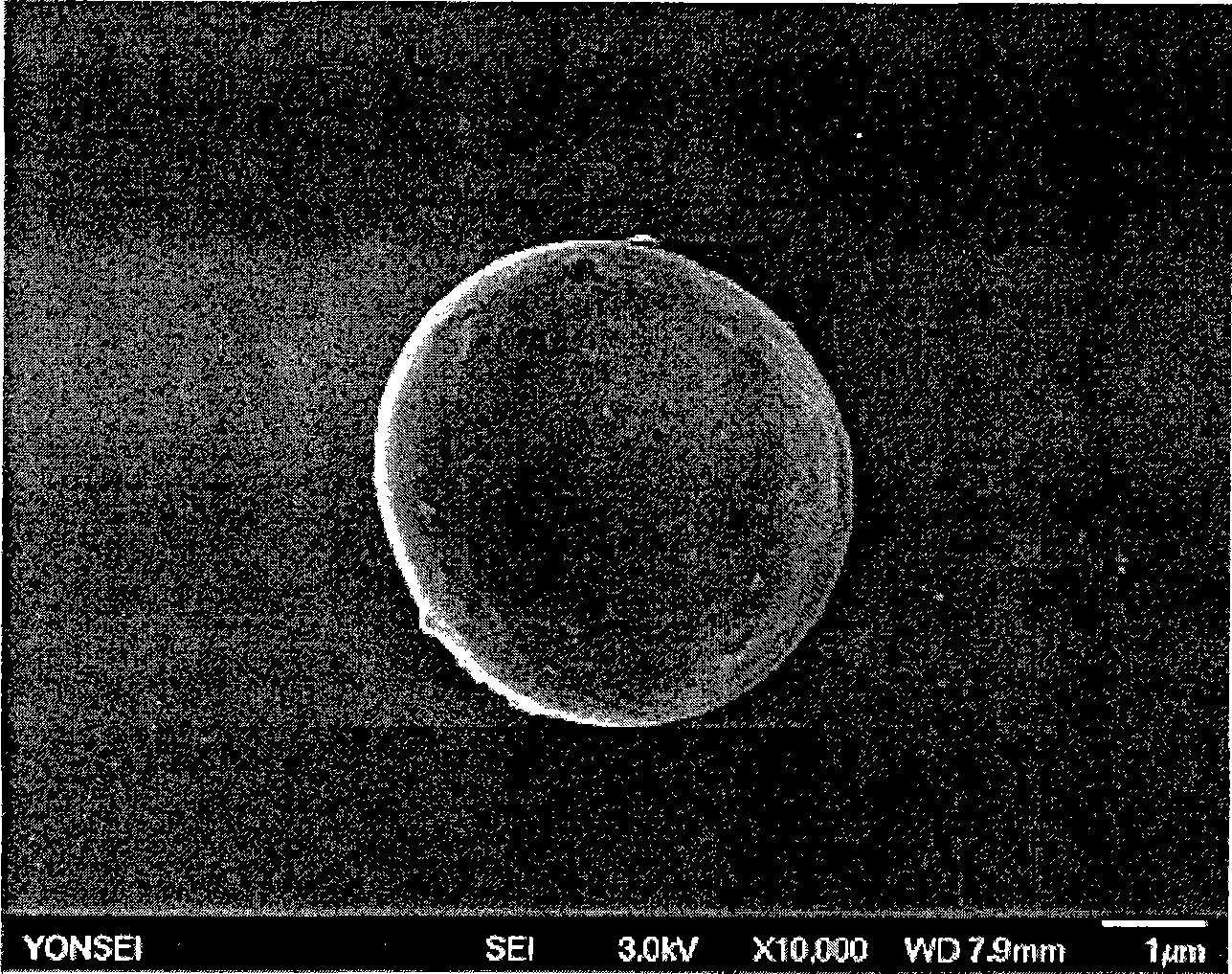

Image

Examples

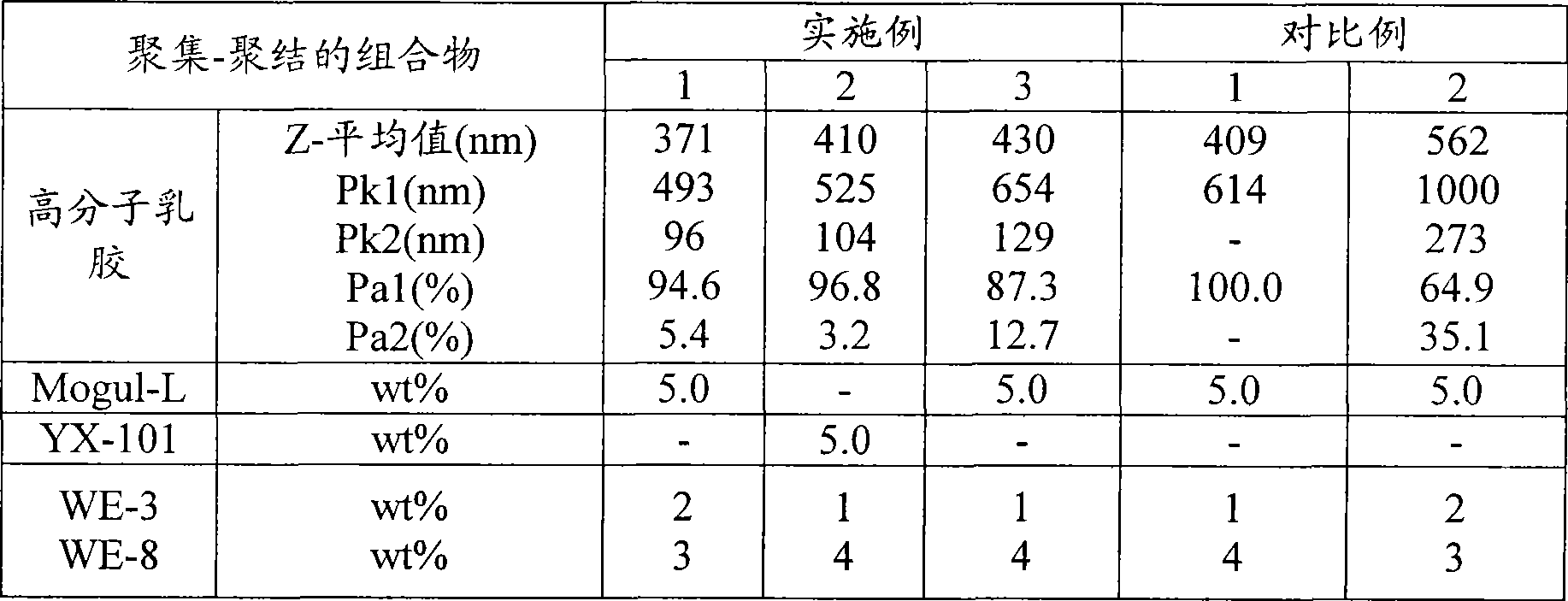

Embodiment 1

[0083] The deionized water of 407g, carbon black (Mogul-L, DIC), wax (Esterwax, WE-3 and WE-8) and the styrene-acrylic acid copolymer latex of 246g are put into the reactor of 1L and use flat impeller to Stir at 150 rpm for 10 minutes. After stirring, adjust the pH to 10 and inject 0.05M MgCl 2 solution. Then, the temperature was raised to 85° C. to perform aggregation-coalescence for 4 hours. The latex used is shown in Table 1. Subsequently, the pH was adjusted to 9 and the solution was gradually heated. When the particle shape was formed after heating for about 6 hours, the solution was cooled and filtered to obtain toner particles. Performance results are shown in Table 2.

Embodiment 2

[0085] The deionized water of 407g, yellow pigment (YX-101, DIC), wax (Esterwax, WE-3 and WE-8) and the styrene-acrylic acid copolymer latex of 246g are dropped in the reactor of 1L and with flat impeller Stir at 150 rpm for 10 minutes. After stirring, adjust the pH to 9 and inject 0.05M MgCl 2 solution. Then, the temperature was gradually raised to 90° C. for aggregation-coalescence. When the particle size reaches 5.0-5.5 μm, the pH is adjusted to 11 and aggregation-coalescence is performed. Latex used in embodiment 2 is as shown in table 1. When the particle shape was formed after heating for about 7 hours, the solution was cooled and filtered to obtain toner particles. Performance results are shown in Table 2.

Embodiment 3

[0087] Experiment with the same method as in Example 1. Latex used in embodiment 3 is shown in table 1. Performance results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com