Method and device for downwards leading and continuously casting copper wire covering steel core

A technology of traction device and steel core, applied in the direction of root rod/rod/wire/strip conductor, manufacture of extensible conductor/cable, etc., can solve the problem of short wire length, pollution of electroplating process environment, and poor bonding force of coating method To achieve the effect of reducing the concentricity deviation, prolonging the solidification time, and ensuring the solidification thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

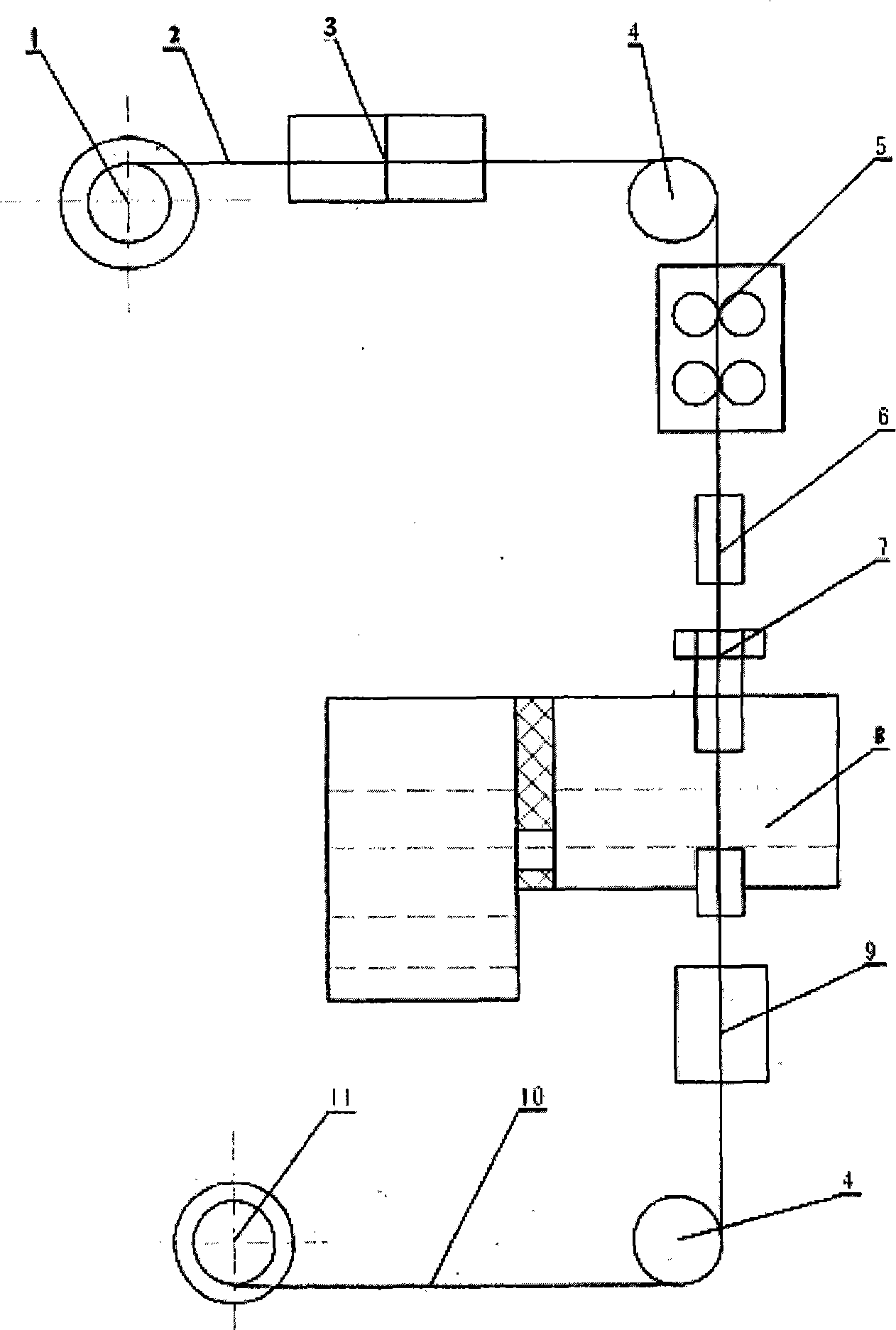

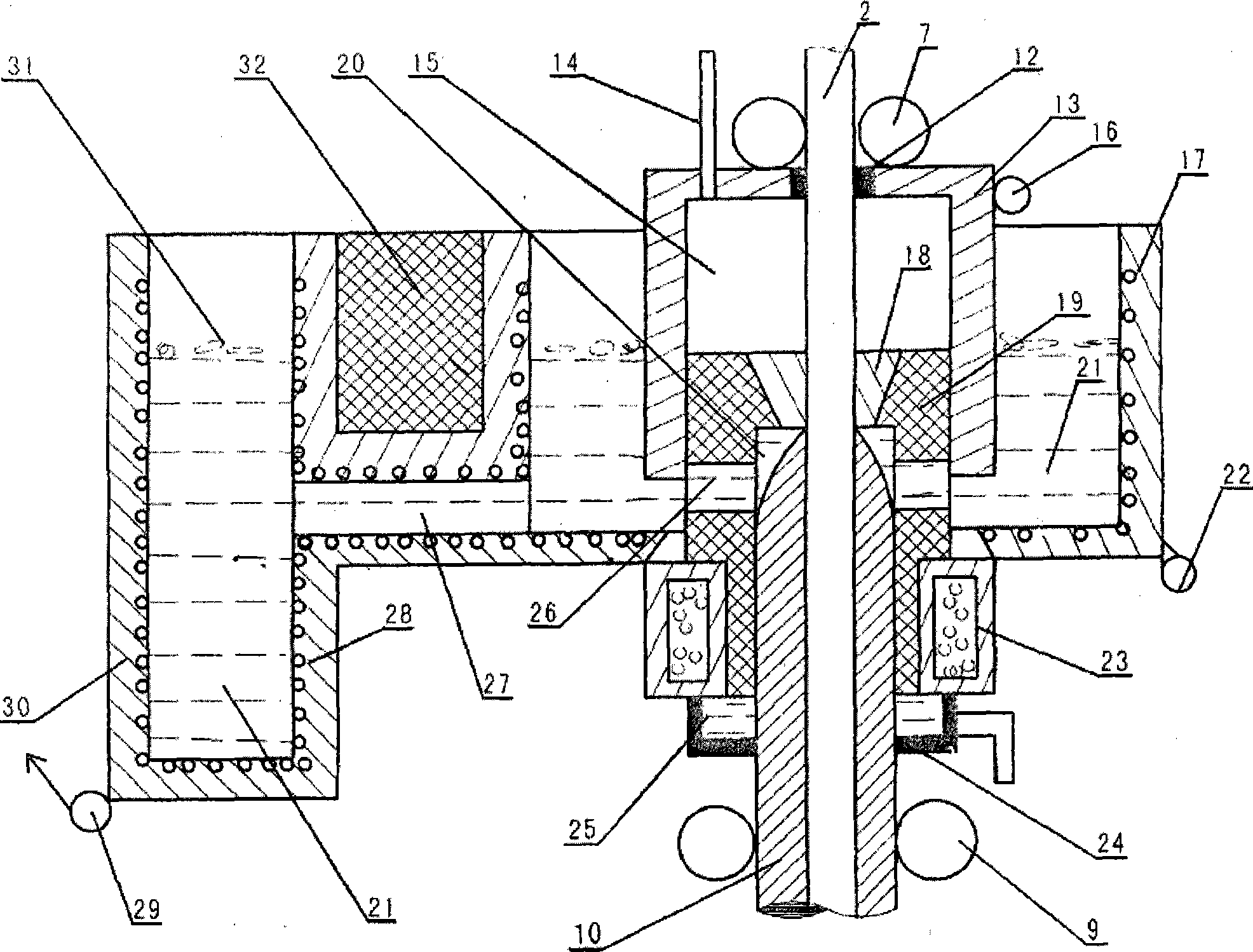

[0017] The steel core copper-clad wire down-leading continuous casting device of the present invention comprises a continuous casting furnace (8), a guiding device (7) and a traction device (9), and the bottom of the continuous casting furnace (8) is provided with a A crystallization mold (19) with interconnected cavities, the crystallization mold (19) has a cooling device (23, 24) and a substantially vertical mold cavity (20), the steel core wire (2) passes through the guide device (7) Through the mold cavity (20) from top to bottom, the pulling device (9) is located at the lower end of the crystallization mold (19), and is used to pull the steel core copper-clad wire (10), and the pulling device (9) is intermittent pulling device.

[0018] When using the device of the present invention to lead down the continuous casting steel core copper-clad wire, the steel core wire (2) passes through the mold cavity (20) from top to bottom in the continuous casting furnace (8), and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com