Headlight structure of vehicle

A technology for headlamps and vehicles, which is applied to road vehicles, motor vehicles, lighting devices, etc., can solve problems such as the unsatisfactory function of displaying position, and achieve the effects of improving pattern design and commerciality, and suppressing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described below with reference to the drawings.

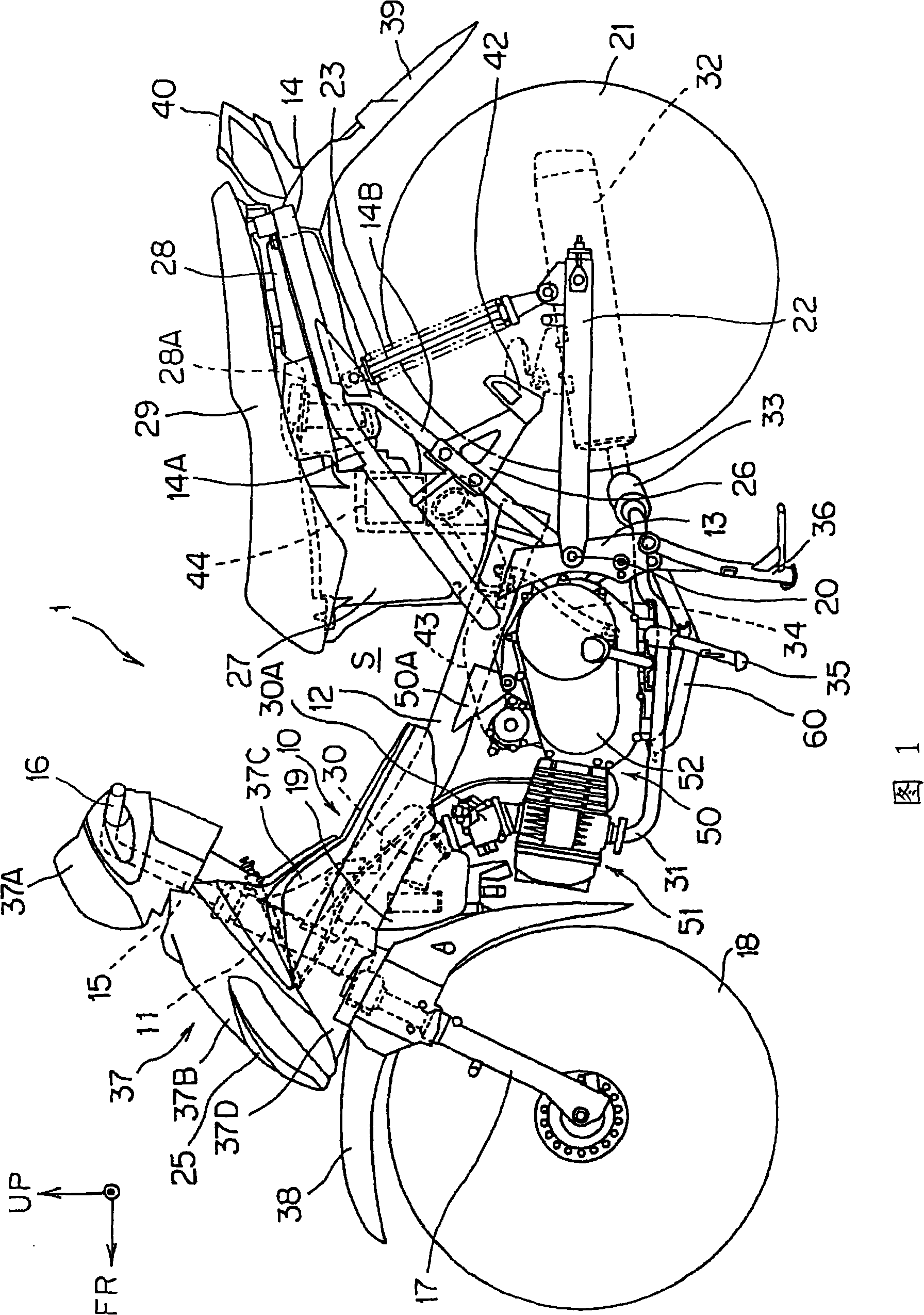

[0045] figure 1 It is a side view showing a motorcycle as an example of a saddle-riding vehicle according to an embodiment of the present invention. In the following description, the directions of front, rear, left, right, and up and down are described with respect to the vehicle body. In the figure, arrow FR indicates the front of the vehicle body, arrow R indicates the right side of the vehicle body, and arrow UP indicates the upper side of the vehicle body.

[0046] The motorcycle 1 includes a suspended body frame 10 . More specifically, the vehicle body frame 10 includes: a head pipe 11, a main pipe 12 extending obliquely downward from the head pipe 11 to the rear of the vehicle body, a pair of left and right pivot plates 13 extending downward from the rear end of the main pipe 12, and A pair of left and right rear frames 14 that are connected to the rear end of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com