Polyvinyl chloride ultraviolet stabilizer, polyvinyl chloride prepared from same and method for preparing same

A technology of polyvinyl chloride and light stabilizer, applied in the polymer field, can solve the problems of poor extraction resistance, compatibility of volatile PVC substrates, low light stabilization efficiency, etc., and achieves low manufacturing cost and improved light stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

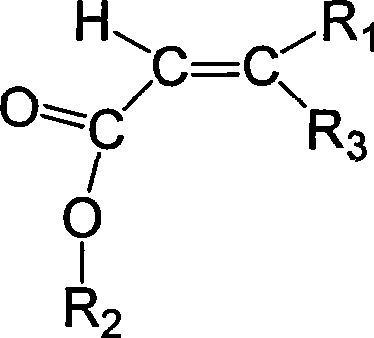

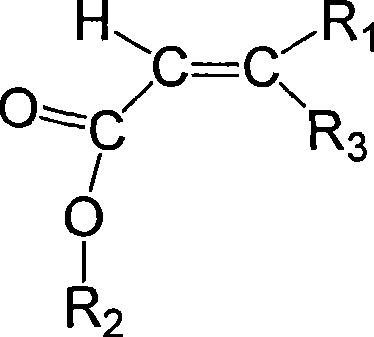

Method used

Image

Examples

Embodiment 1

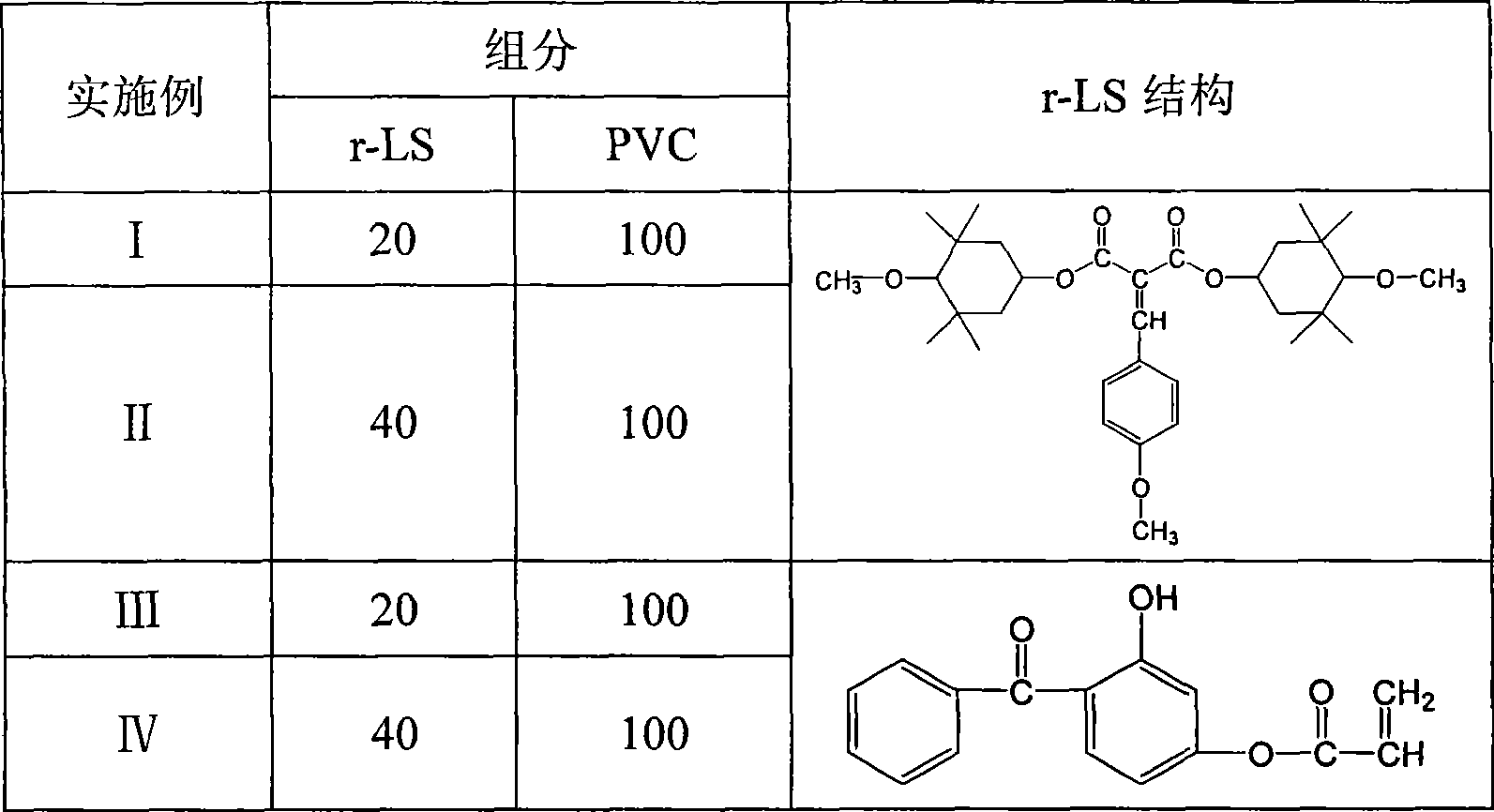

[0035] The preparation of the anti-ultraviolet light stabilizer in Example 1 is to place the pretreated r-LS and PVC resin powder in the vibration milling device according to the ratio at about 30 ° C, and mix and vibrate for 8 hours (rotation speed 800 rpm / points), a new light stabilizer can be prepared.

[0036] The preparation methods of other examples are basically the same as those of Example 1.

[0037] Provide the embodiment and the test result of the light-resistant PVC containing the photostabilizer provided by the invention below

[0038] Example 1:

[0039] 3phr novel ultraviolet light stabilizer I, 1phr dibasic lead phosphite, 2phr tribasic lead sulfate, 0.5phr stearic acid are added in the PVC resin (PVC-SG8 of Yibin Tianyuan chemical factory) of 100phr respectively, in double Mix in a roller mixer at about 170°C for about 8 minutes, and then press at about 180°C to form sheets and plates of required thickness for testing. (1#: PVC sample added with 0.5phr rea...

Embodiment 2

[0043] 1.8phr novel light stabilizer II, 1phr dibasic lead phosphite, 2phr tribasic lead sulfate, 0.5phr stearic acid are added in the PVC resin (PVC-SG8 of Yibin Tianyuan Chemical Factory) of 100phr respectively, in double Knead at about 170°C for about 10 minutes in a roller kneader, and then press at about 180°C to form sheets and plates of required thickness for performance testing after accelerated aging. (1#: PVC sample added with 0.5phr reactive light stabilizer; 2#: PVC sample added with 1.8phr light stabilizer after vibration grinding)

[0044]

Embodiment 3

[0046] 3phr new light stabilizer III, 1phr dibasic lead phosphite, 2phr tribasic lead sulfate, 0.5phr stearic acid are added in 100phr PVC resin (PVC-SG8, Yibin Tianyuan Chemical Factory) respectively. Knead in a kneader at about 170°C for about 10 minutes, and then press at about 180°C to form sheets and plates of required thickness for performance testing after accelerated aging. (1#: PVC sample added with 0.5phr reactive light stabilizer; 2#: PVC sample added with 3phr vibration-milled light stabilizer)

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com