A method for manufacturing a composite coating material

A technology of composite coating and manufacturing method, which is applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., to achieve the effects of cost reduction, enhanced waterproof and wear resistance, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

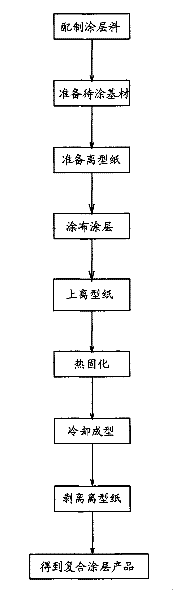

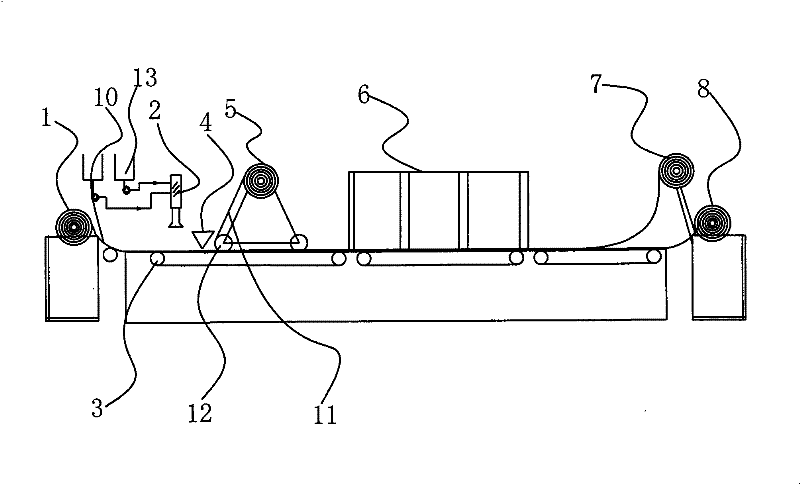

Method used

Image

Examples

Embodiment 1

[0038] Fully mix 40Kg diphenylmethane diisocyanate, 40Kg polyether polyol and 2Kg colorant in a mixer, then prepare the foam base material, prepare the release paper, coat the coating, apply the release paper, heat cure, Steps such as cooling obtain composite coating product. The thermal curing temperature is 25° C., and the coating thickness of the finally obtained composite coating material is 0.1 mm.

Embodiment 2

[0040] Fully mix 50Kg diphenylmethane diisocyanate, 49Kg polyether polyol and 1Kg colorant in a mixer, then prepare the foam substrate, prepare the release paper, coat the coating, apply the release paper, heat cure, Steps such as cooling obtain composite coating product. The thermal curing temperature is 30° C., and the coating thickness of the finally obtained composite coating material is 0.5 mm.

Embodiment 3

[0042] Fully mix 58Kg diphenylmethane diisocyanate, 40Kg polyether polyol and 2Kg colorant in a mixer, then prepare the leather substrate, prepare the release paper, apply the coating, apply the release paper, heat cure, and cool and other steps to obtain composite coating products. The thermal curing temperature is 40° C., and the coating thickness of the finally obtained composite coating material is 1 mm.

[0043] The composite coating material produced by the method of the invention has significantly enhanced tensile strength, waterproof and abrasion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com