Method for grinding a machine part, and grinding machine for carrying out said method

A machine component and grinding technology, which is applied in the field of grinding machine components and grinding machines for implementing the same, can solve the problems of unattainable and unachievable grinding, and achieve the effect of improving size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

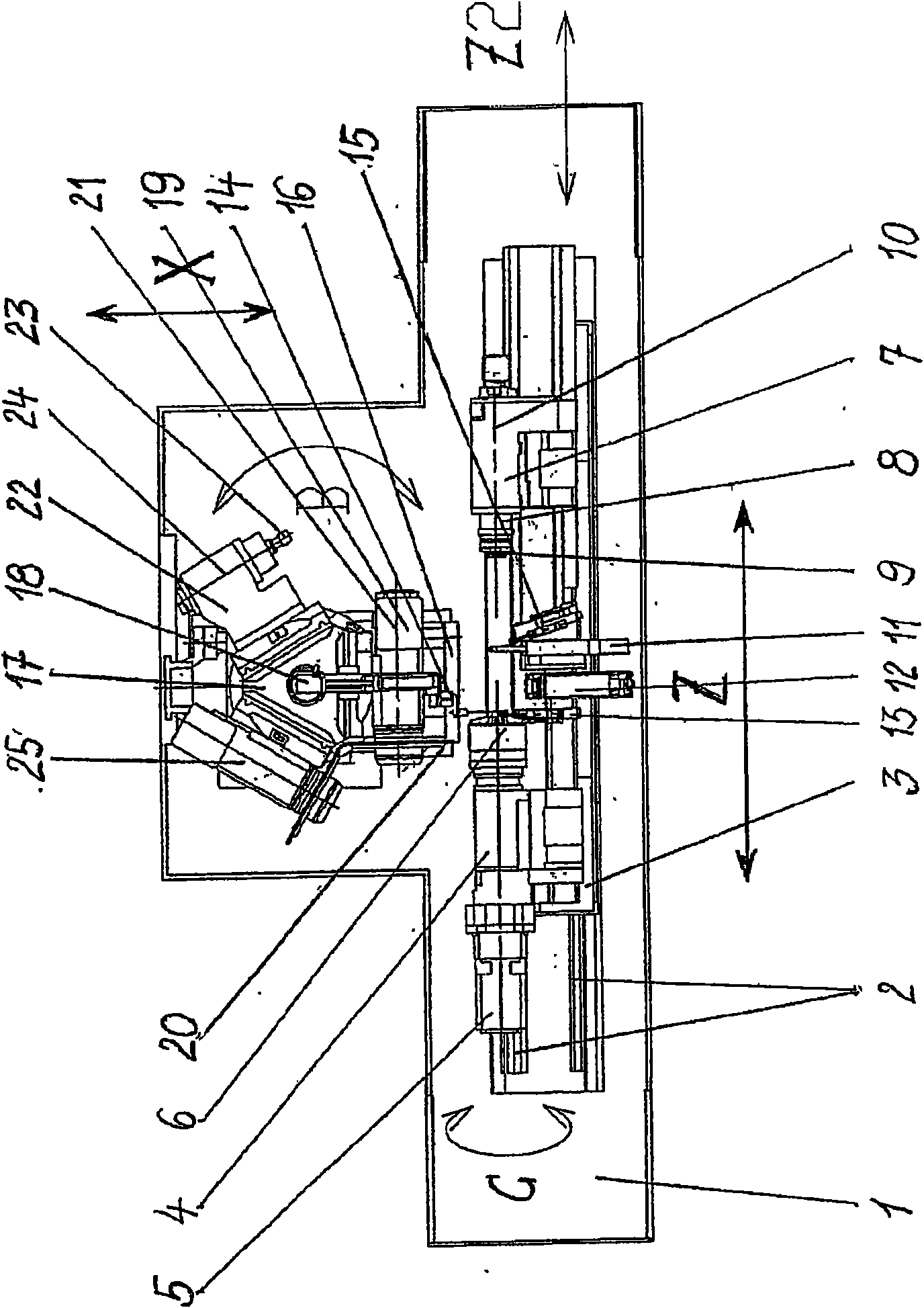

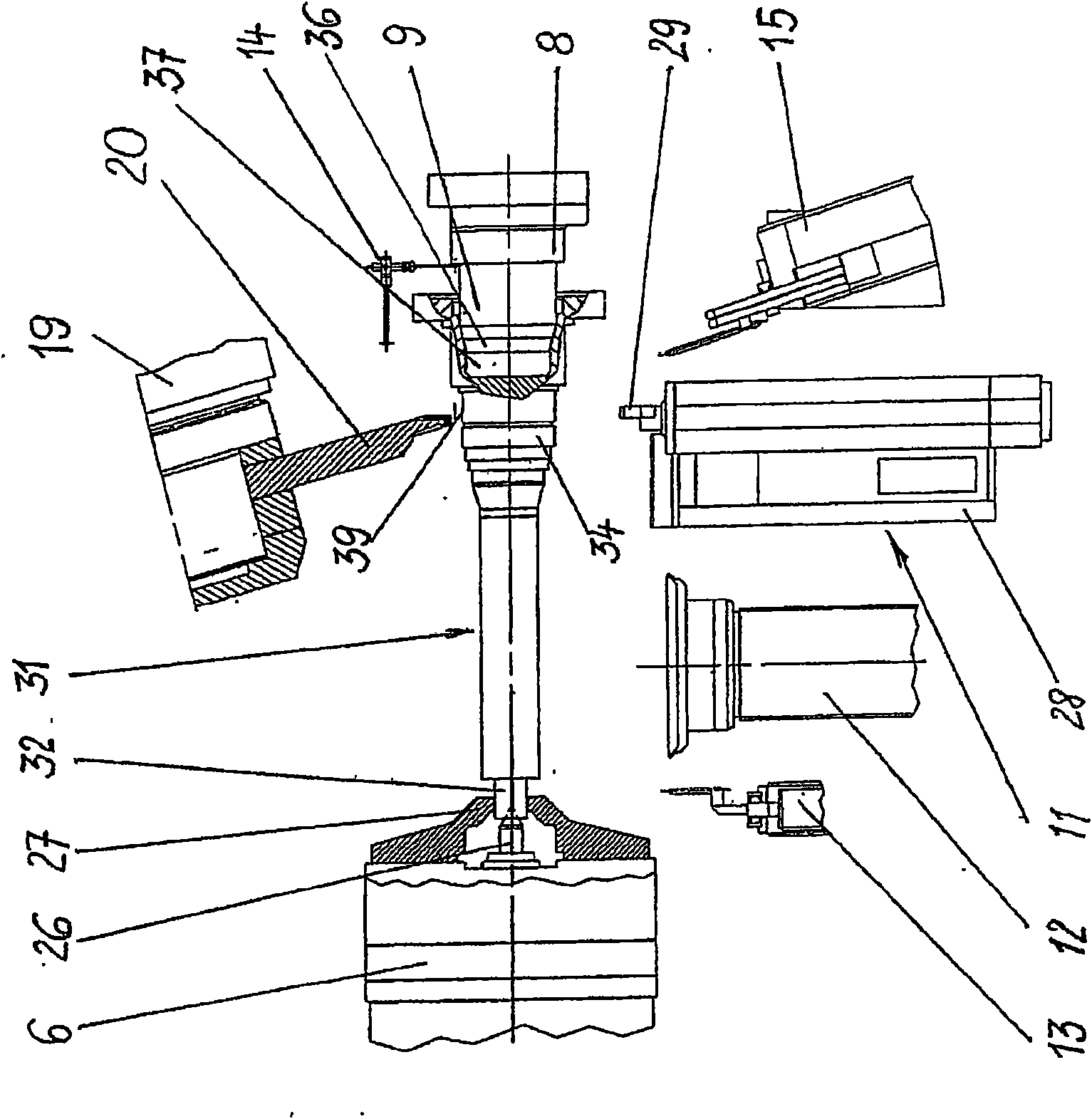

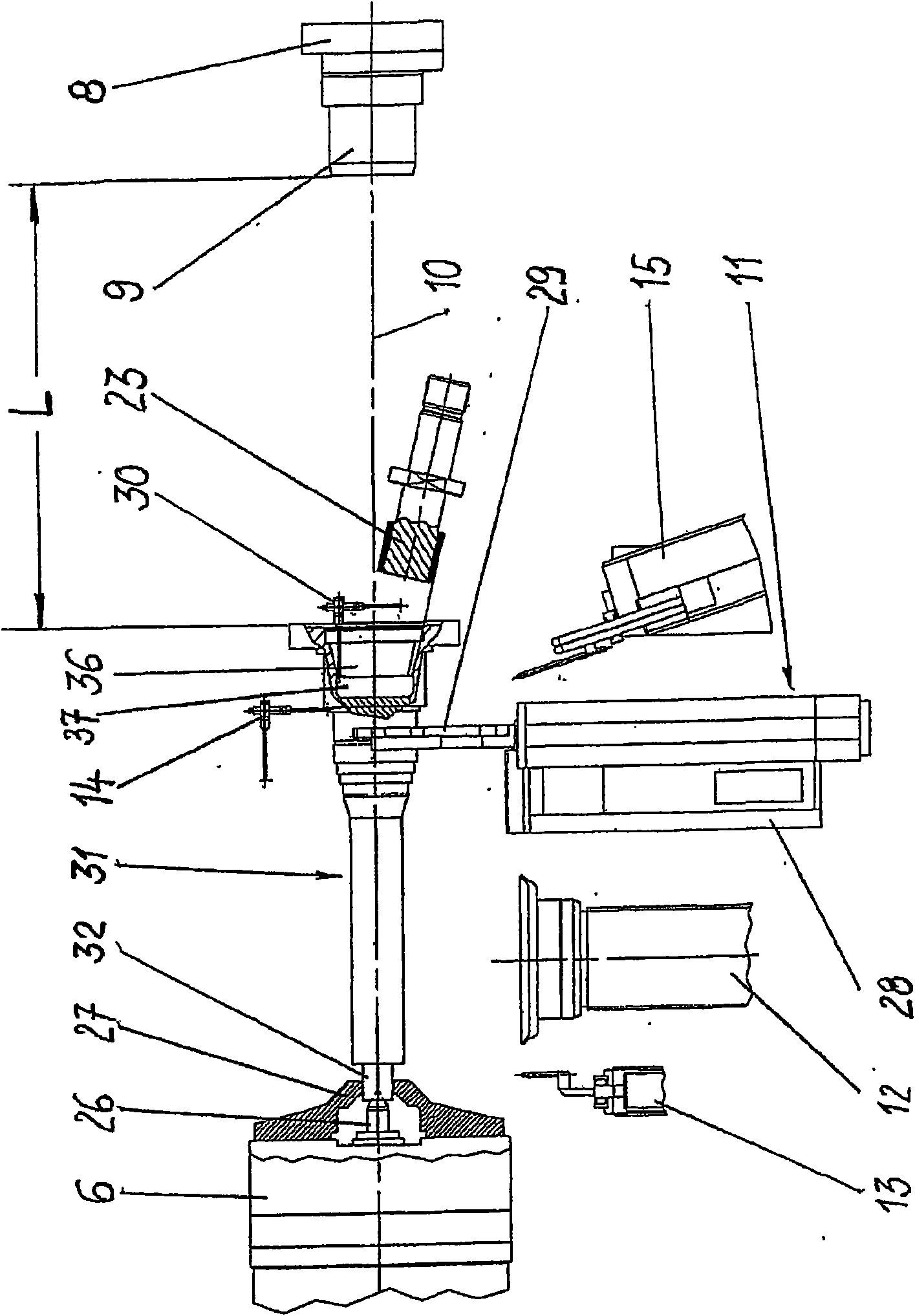

[0030] figure 1 and Figure 8 The grinding machine shown in is basically based on the typical construction of a universal, round and non-round grinding machine. On the bed 1 there is a guide rail 2, on which there is a grinding table 3 that can move longitudinally along the so-called Z2 axis, on which a headstock 4 with a drive motor 5 and a chuck 6 is arranged , the chuck 6 is used to clamp the machine parts 31, and the chuck 6 is provided with a centering tip 26 and detachable jaws 27 for this purpose (see Figures 2 to 4 ).

[0031] A tailstock 7 is provided coaxially with the headstock 4 and at a distance therefrom in the axial direction. Tailstock 7 has a conventional tailstock sleeve 8 terminating in a fitted sleeve tip 9 ( image 3 ). The tailstock 7 is moved longitudinally on the grinding table 3, wherein, as usual, the machine part 31 is clamped between the headstock 4 and the tailstock 7 with a common axis of rotation 10 (cf. Figure 2 to Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com