Assembling unit for filtering, heating and blowing and configuration method thereof

A technology of blower and blower motor, applied in the field of air supply system, can solve the problems of inability to adapt to modern technology level, harsh indoor air environment, obstruction of process production line, etc., and achieve the effect of convenient and flexible layout, beautiful appearance, economical and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

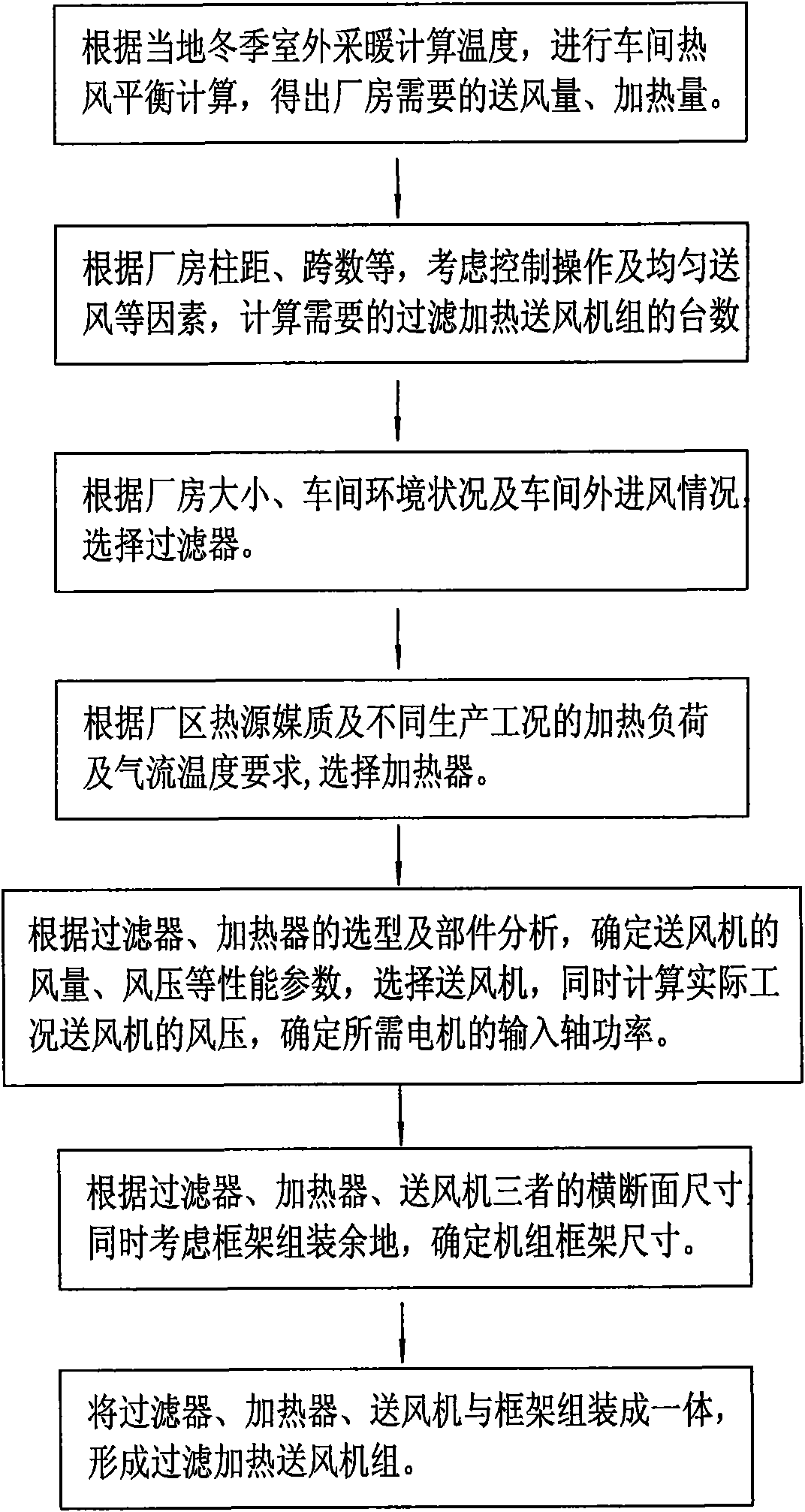

Method used

Image

Examples

Embodiment Construction

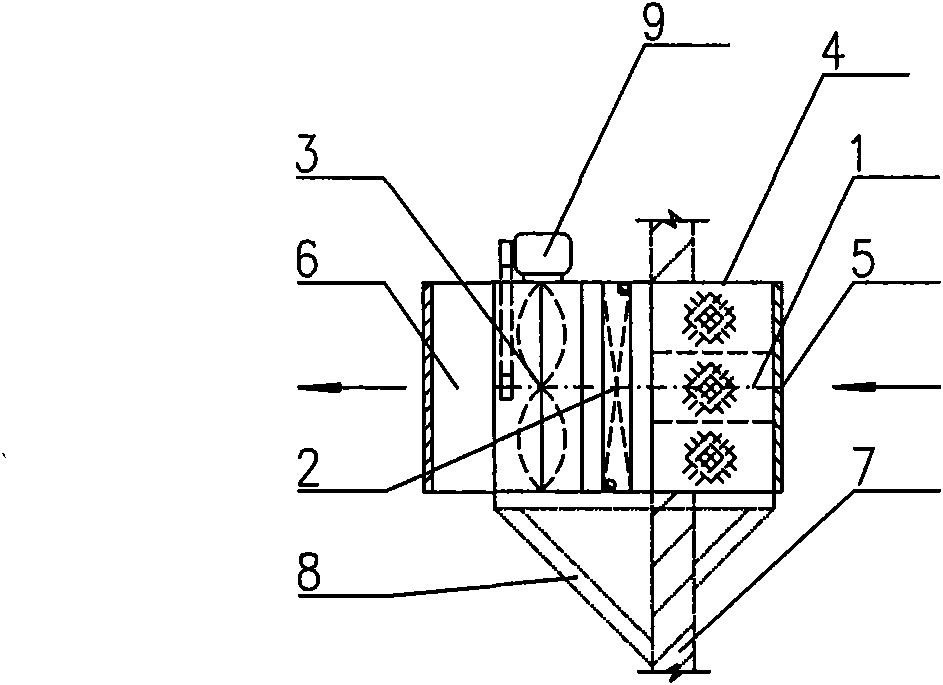

[0020] A factory is located in a severe cold and sandy area. A tall two-story factory building is 144m long, 32m wide, and 28m high. The process tank in the workshop emits acid mist and organic volatiles. In winter, a large amount of heat load is taken away through the exhaust air of the purification system and the overall ventilation. Considering the limited workshop space, avoiding the collision of air supply pipes and other professional facilities, and reducing the energy consumption of the air supply system, the filter heating air supply unit of the present invention is designed, heated by 0.2MPa high-pressure steam, and the fresh air is filtered and heated to 35°C. Bring it indoors.

[0021] Due to the limitation of the configuration space of the workshop and the performance matching of each equipment of the filter heating and blowing unit, the specifications and dimensions of the unit are correspondingly restricted, thus limiting the range of performance parameters such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com