Filling device of liquid propellant and method thereof

A liquid propellant and filling device technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as residual hydrazine propellant in pipelines, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

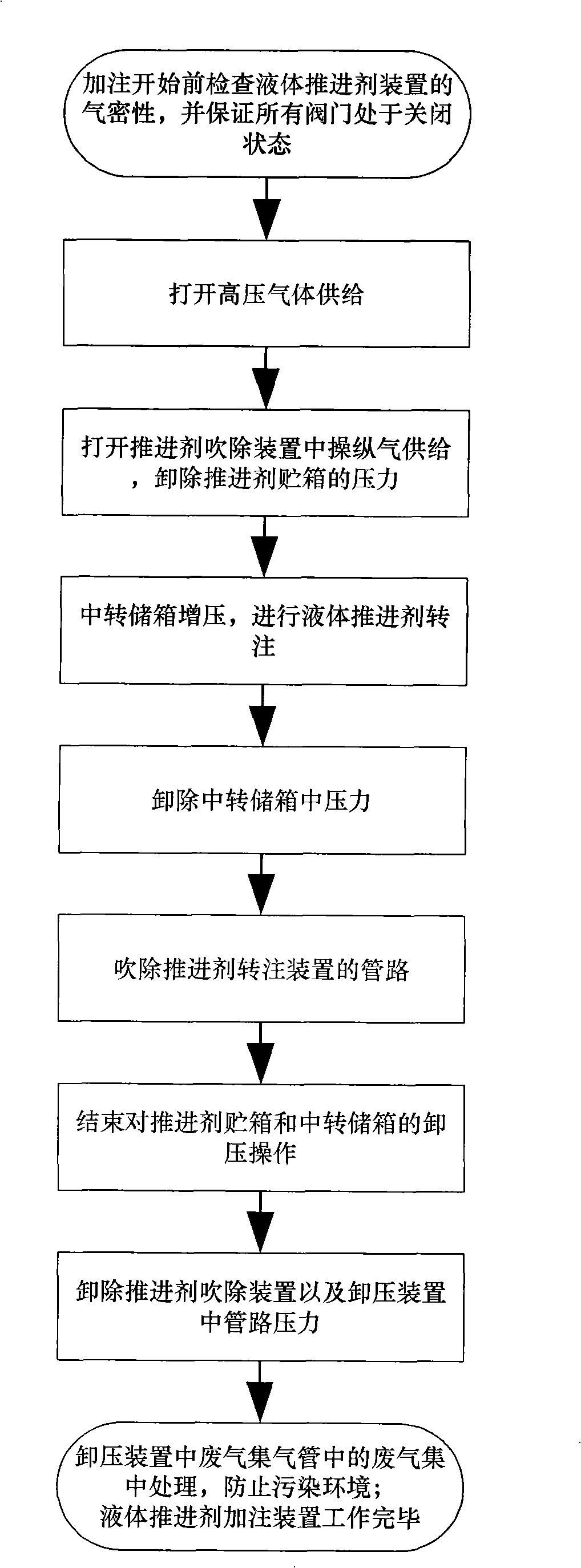

[0036] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

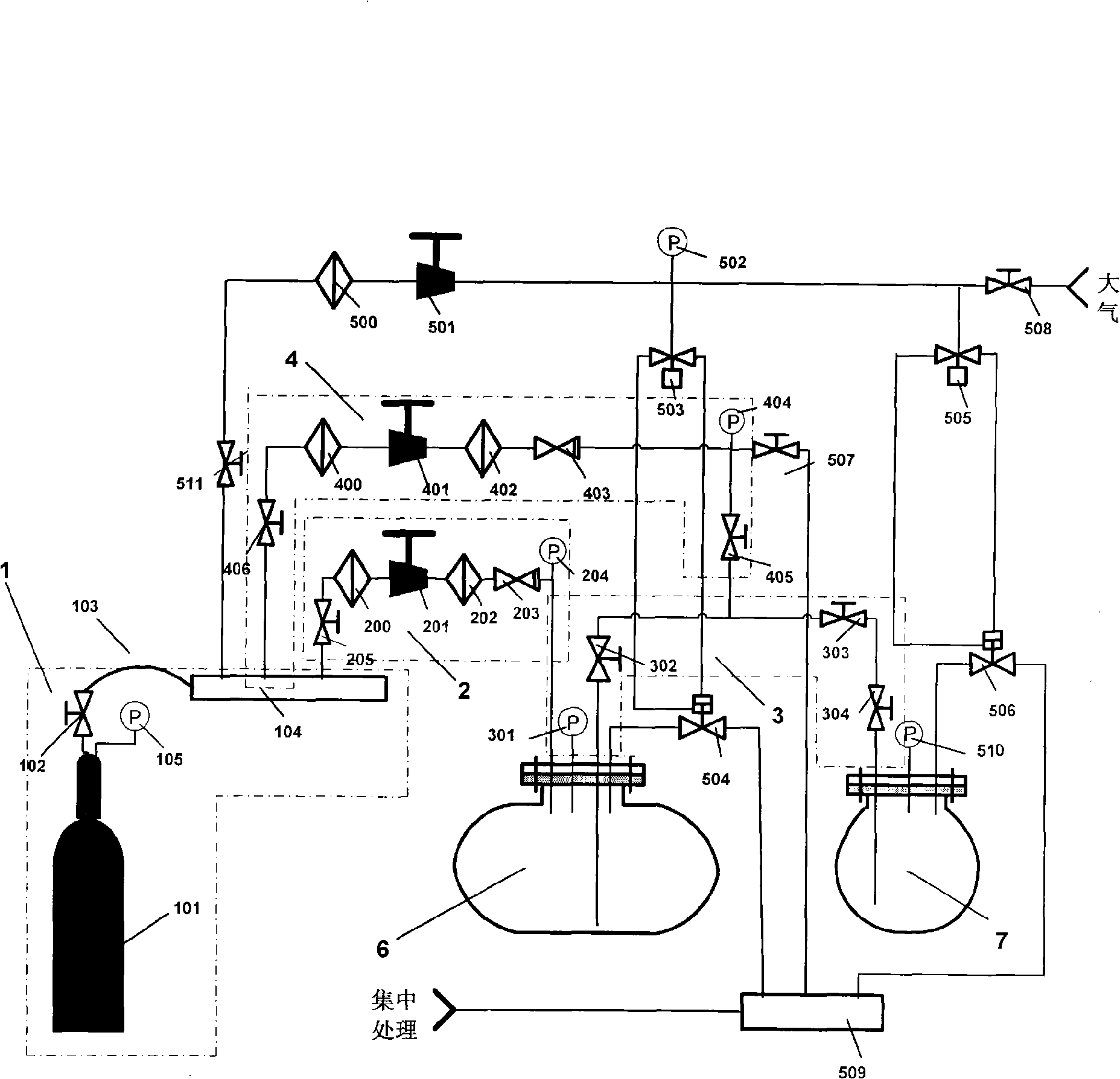

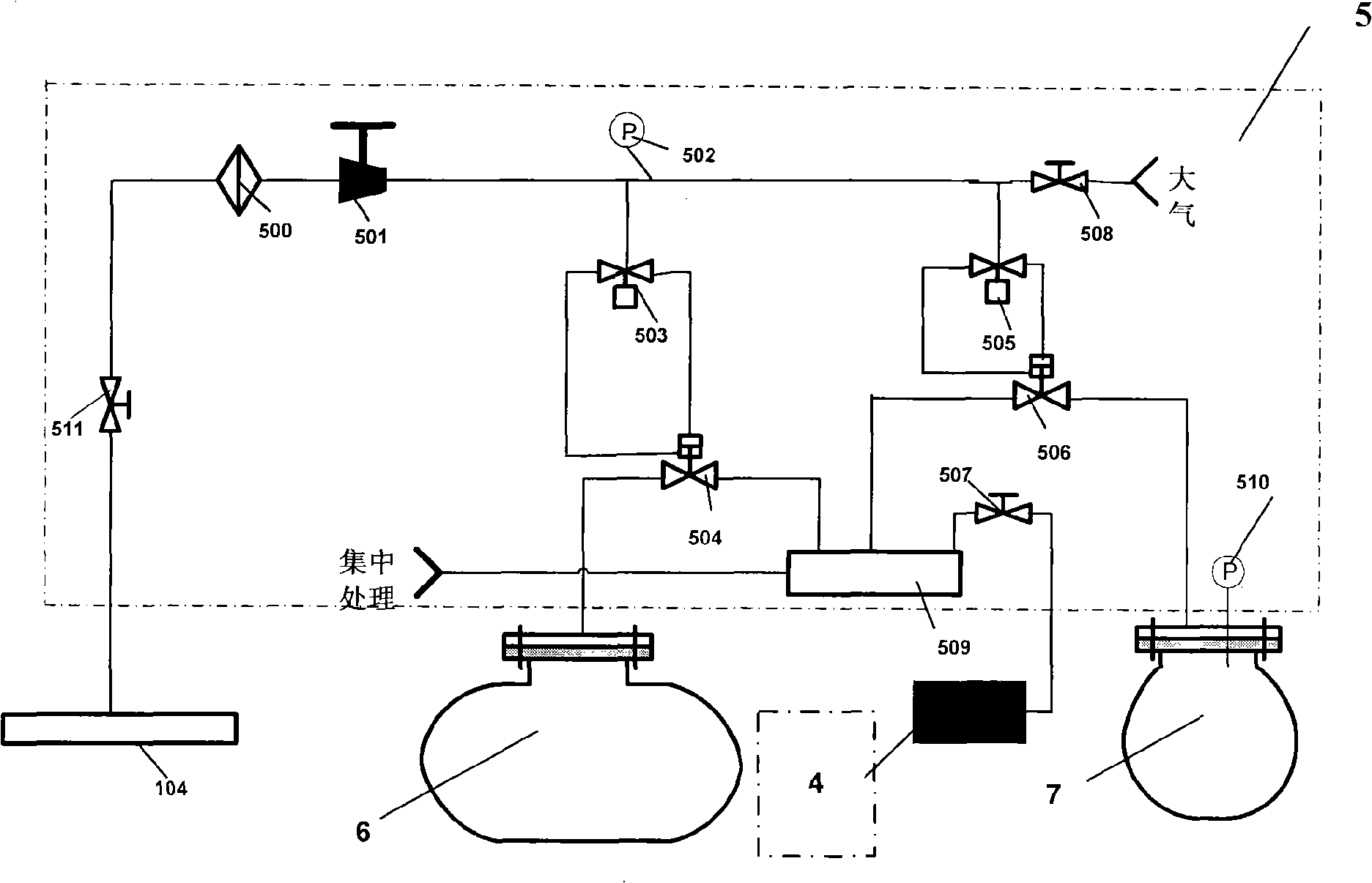

[0037] The liquid propellant filling device consists of a high-pressure gas source device 1, a transfer tank booster device 2, a propellant transfer device 3, a propellant blow-off device 4, a pressure relief device 5, a transfer tank 6 and a propellant storage tank 7 composition, see attached figure 1 shown.

[0038] The high-pressure gas source device 1 provides pressurized gas for the pressurization device 2 of the transfer storage tank, blow-off gas for the propellant blow-off device 4, and operating gas for the pressure relief device 5; the pressurization device 2 of the transfer storage tank supplies The dump tank 6 is pressurized; the propellant transfer device 3 transfers the liquid propellant from the transfer tank 6 to the propellant storage tank 7; the blow-off device 4 blows off the propellant transfer device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com