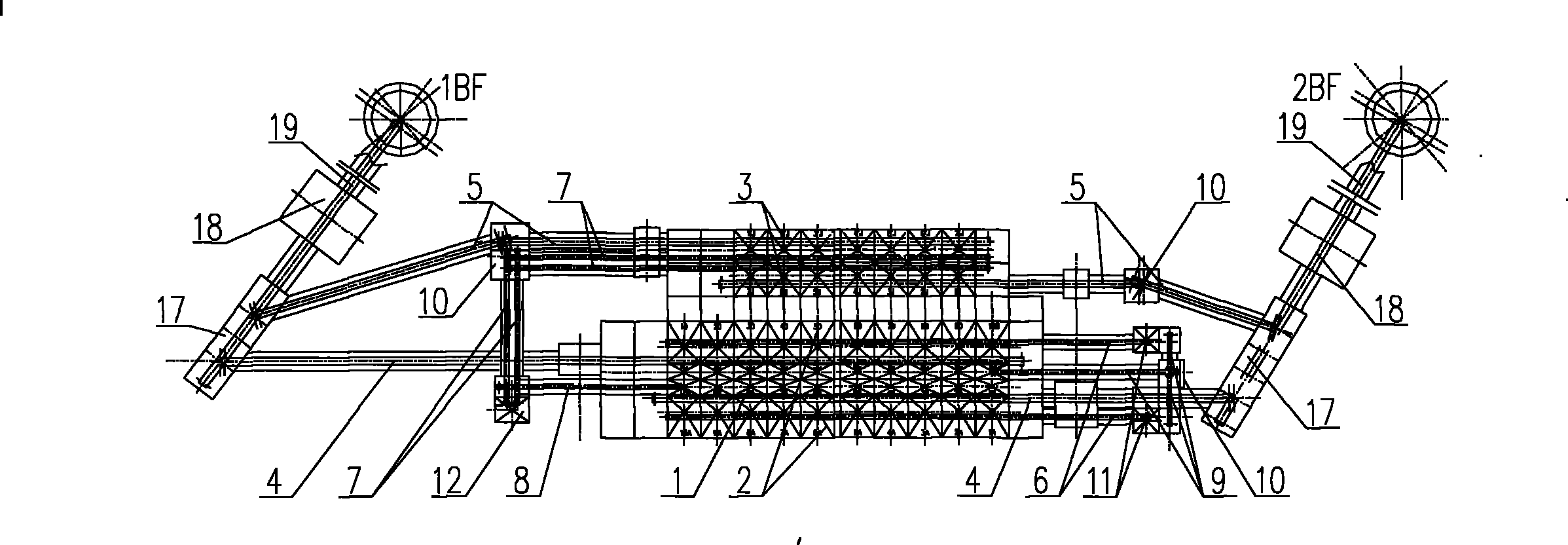

Combination technique arrangement of two coke and ore tank systems

A mine trough and process technology, which is applied in the direction of bell and funnel arrangement, etc., can solve the problems of installation, maintenance, overhaul, increase of personnel, large occupied area, and increased failure rate, so as to save time for equipment maintenance and overhaul, and occupy an area The effect of being small and having a small number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

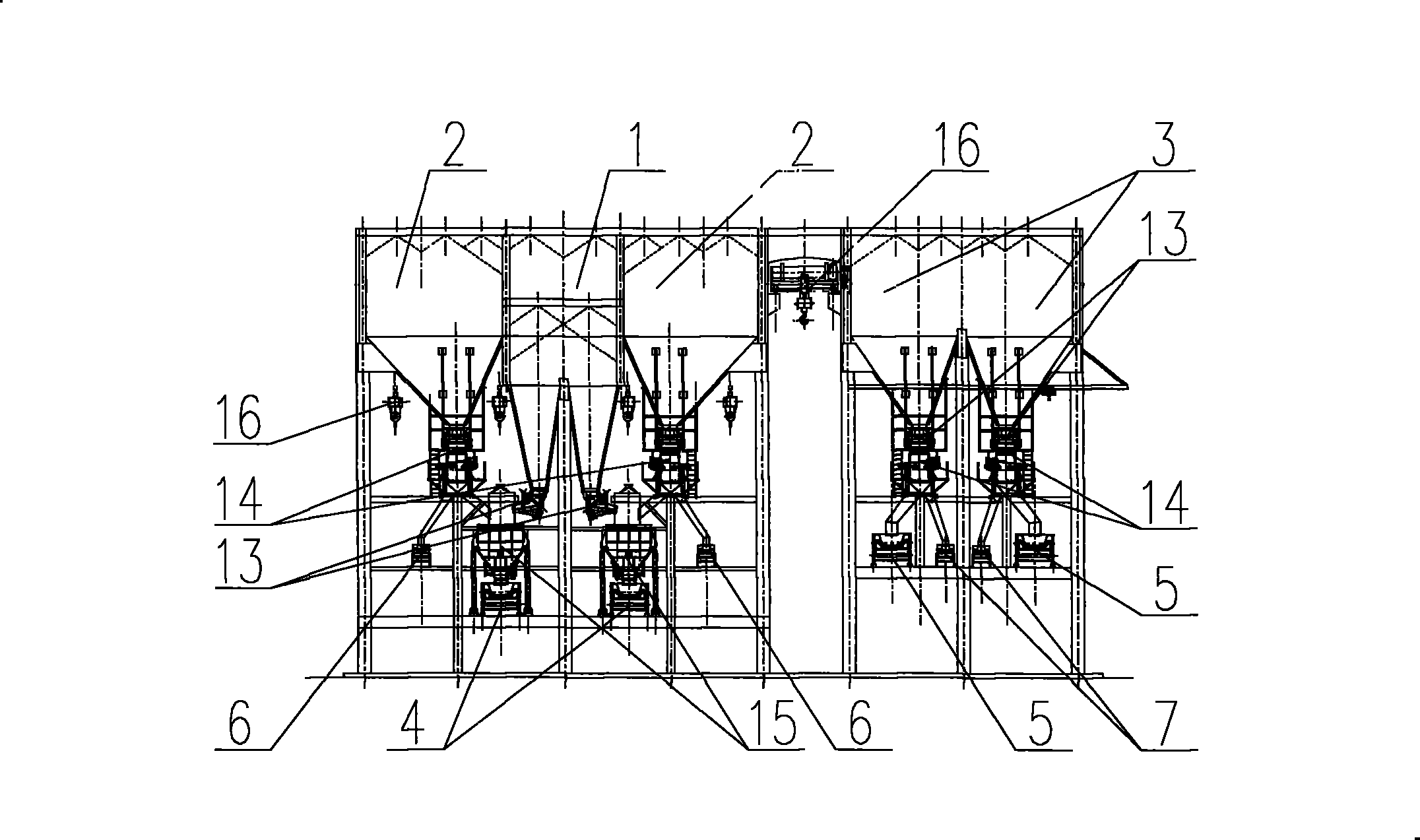

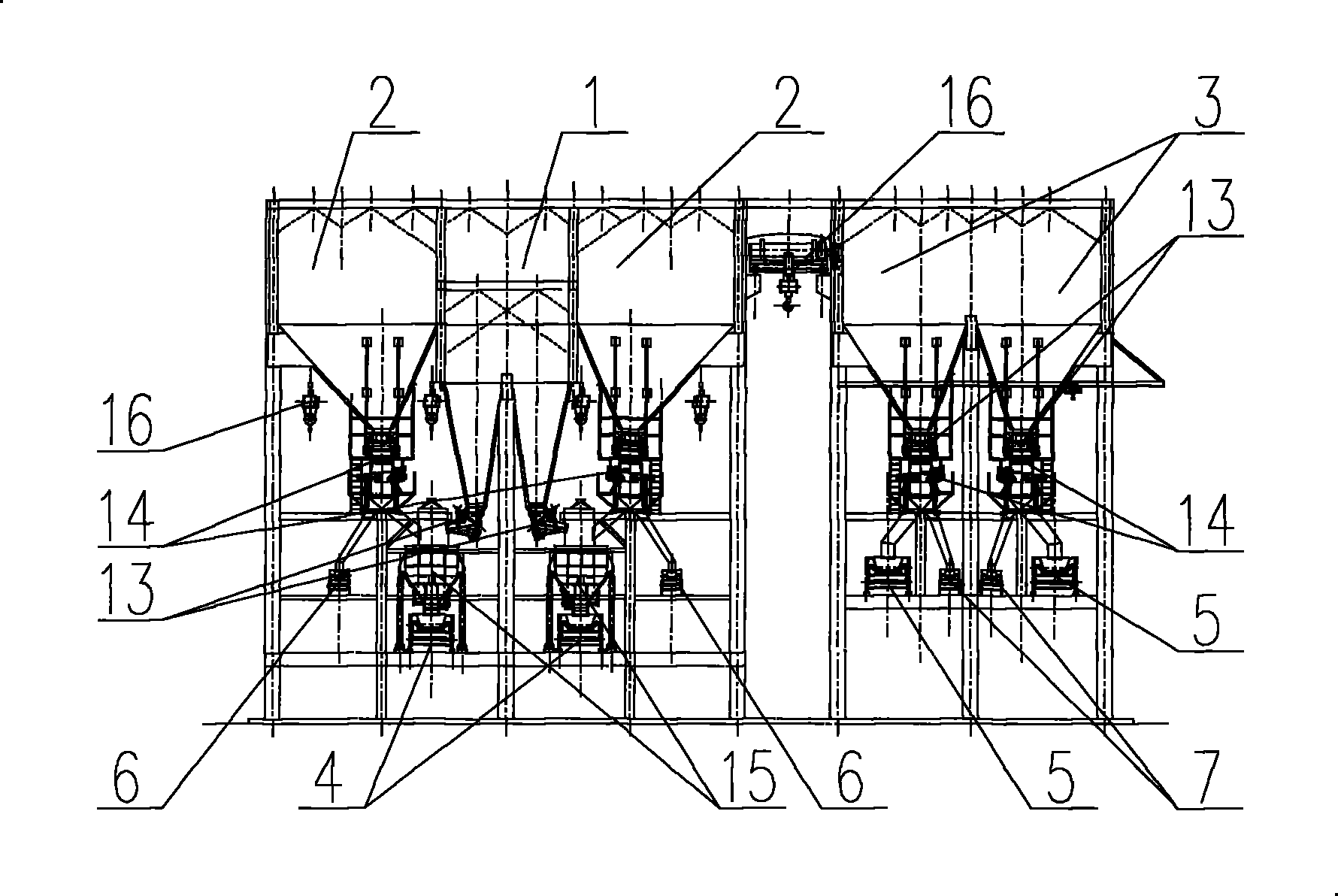

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Two blast furnaces 1BF and 2BF; the sinter tank 2 of each blast furnace is arranged separately; the miscellaneous ore tank 1 and coke tank 3 of the two blast furnaces are arranged in a combined manner, and the miscellaneous ore tank 1 is arranged in the middle of the sinter tank 2 and is connected with the sinter Slot 2 is arranged one-to-one; a belt conveyor is arranged on the upper part of the coke ore tank; a feeding device 13, a screening device 14 and an inspection device 16 are installed under the sinter tank 2 and coke tank 3; A feeding device 13 is provided, and a screening device 14 may also be provided below it.

[0014] The materials that pass the screening under the mine tank or need to be weighed are discharged to the ore belt conveyor 4 under the tank after being weighed by the weighing device 15, and are transported by the main belt conveyor 19 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com