Method for preparing high content soybean oligosaccharide by simulated moving bed separation

A technology of soybean oligosaccharide and simulated moving bed, which is applied in separation methods, preparation of oligosaccharides and sugar derivatives, etc., can solve the problems of high separation cost, low separation strength, large amount of stationary phase and mobile phase, etc. The effect of short process, strong operability and mature process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific implementation examples

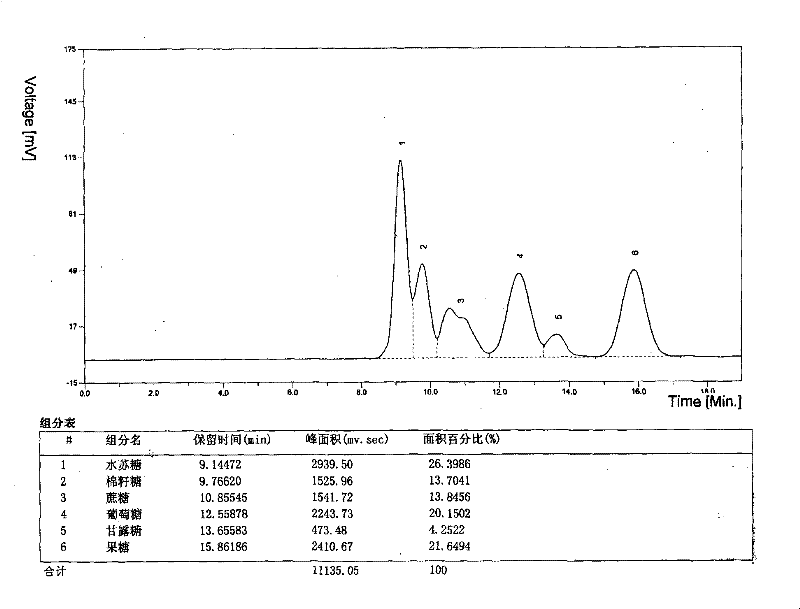

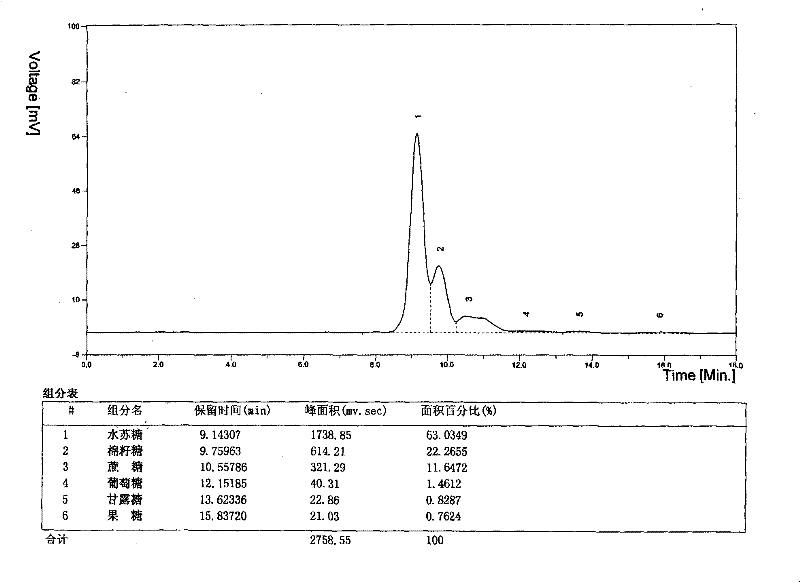

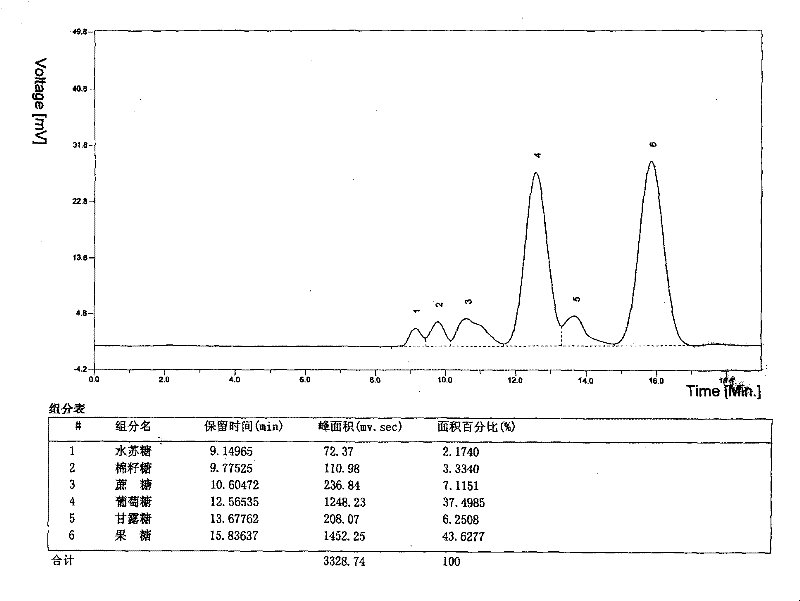

[0017] The invention provides an industrially feasible method for purifying soybean oligosaccharides. The method uses simulated moving bed chromatographic separation technology, continuous feed and continuous discharge, and has the characteristics of high degree of automation, simple operation, high separation strength, high concentration of separated products, and high content of main products.

[0018] According to the method of the present invention, the used separating agent is calcium type or sodium type cation exchange resin or porous calcium-Y type molecular sieve, all of which are sold in the market and have very stable performance. The eluent used is purified water, which is economical and readily available.

[0019] According to the method of the present invention, a simulated moving bed chromatographic separation device equipped with the above-mentioned separating agent is used. The separation device is composed of 4 or 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com