Power-free integrated constructed wetland waste water treatment technology

A technology for artificial wetland and sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of increasing investment, no significant promotion of denitrification and denitrification, etc. To achieve the effect of beautifying the surrounding environment, free and convenient water level adjustment, and uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

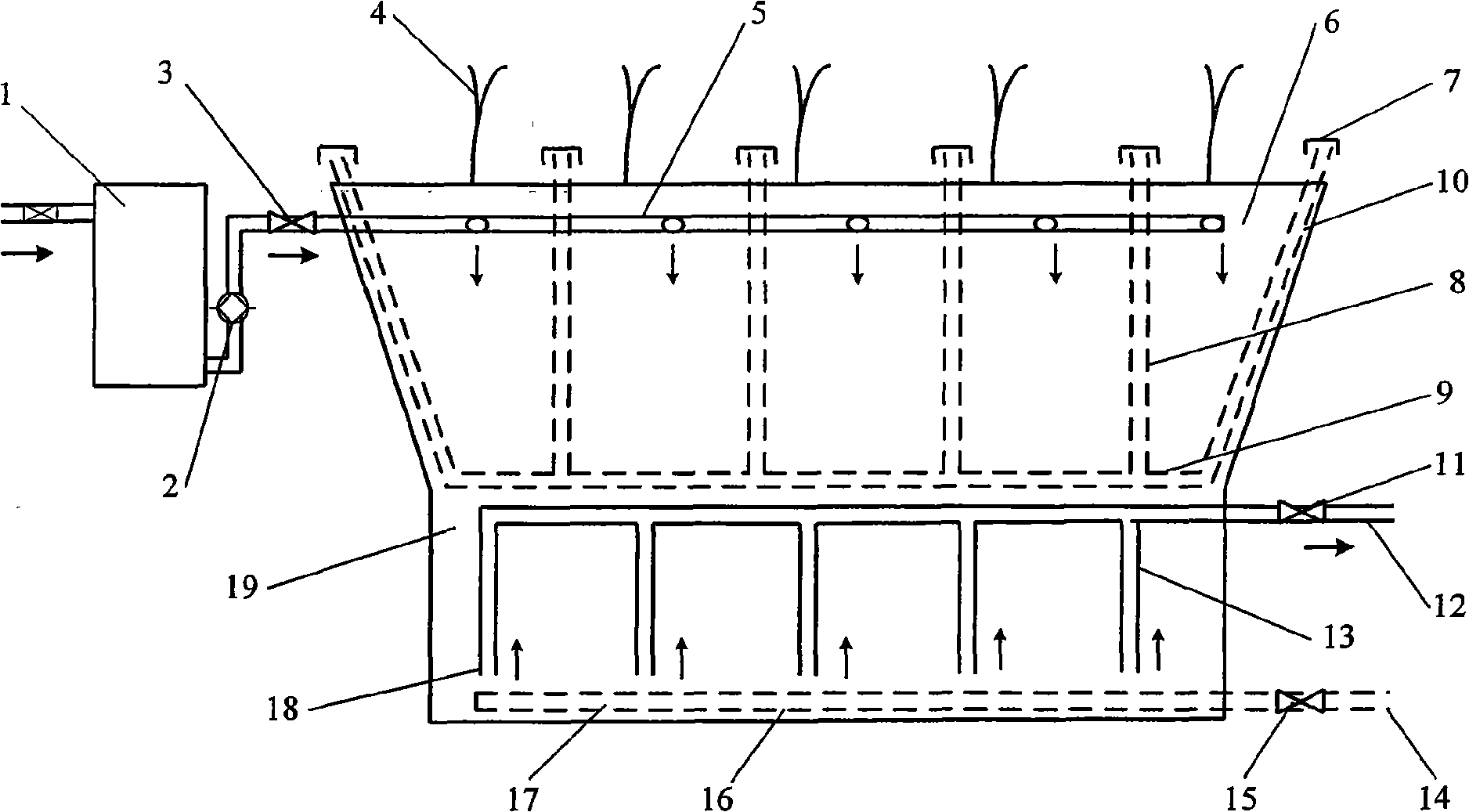

[0026] The technical solutions of the present invention will be further specifically described below through implementation examples and in conjunction with the accompanying drawings.

[0027] In this example, pretreatment is usually done in a three-format sedimentation tank, and the sludge will be cleaned periodically. For sewage with higher concentration, an anaerobic pool can be built at the front end of the filter bed. Good pre-sedimentation treatment is the guarantee for the long-term effective operation of the artificial ecological filter bed, and it can also play a role in regulating the amount and quality of sewage water. The pretreated sewage is lifted by the intermittent sewage pump and evenly distributed to the surface of the artificial substrate in the upper nitrification area of the vertical flow sewage ecological purification tank according to the set control parameters.

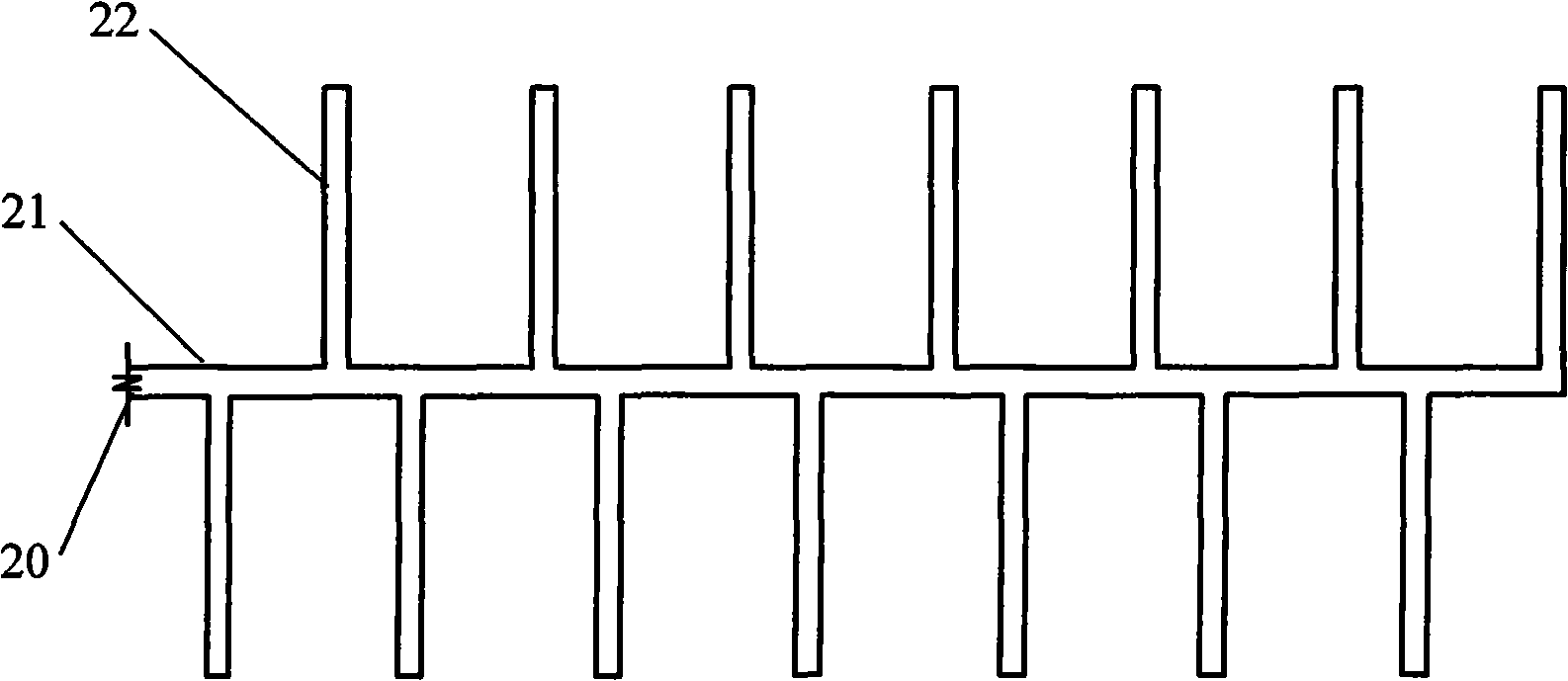

[0028]The main sewage treatment area of the present invention—the vertical flow sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com