Vehicle side mirror

A technology for reversing mirrors and vehicles, which is applied to vehicle parts, optical observation devices, transportation and packaging, etc. It can solve the problems of incomplete identification of dead-end areas, illusions caused by drivers, accidental traffic accidents, etc., to achieve easy identification, prevent illusions, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

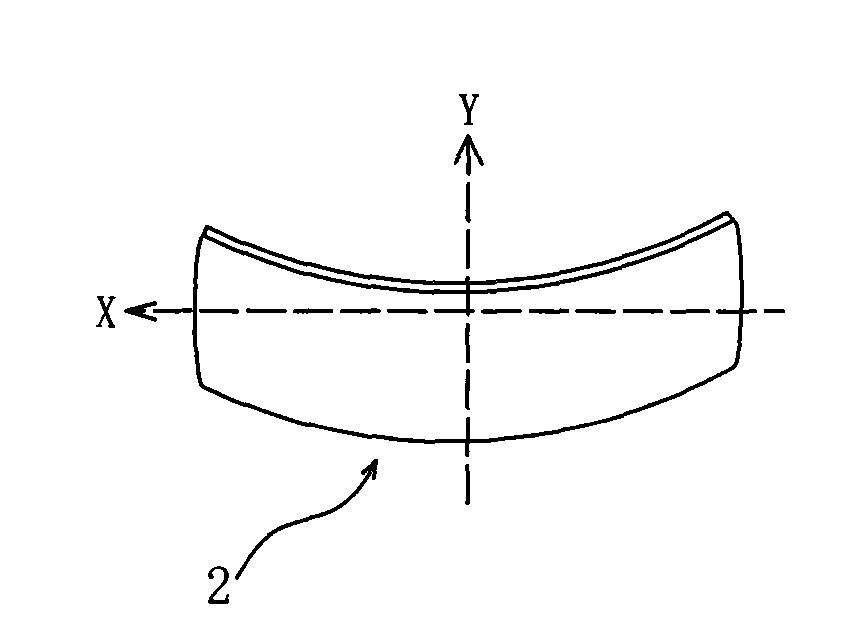

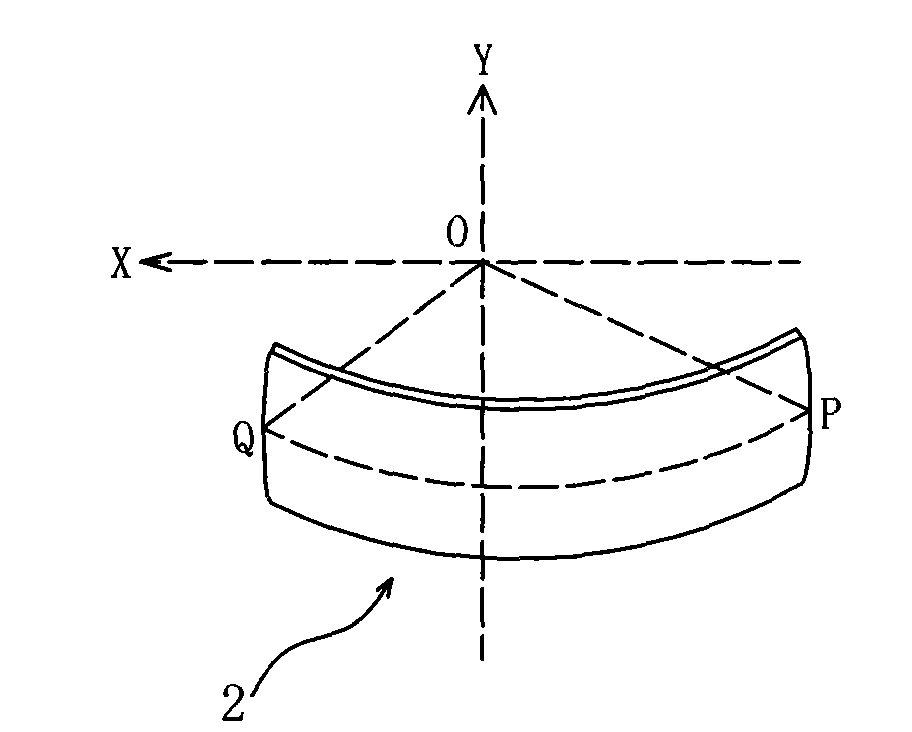

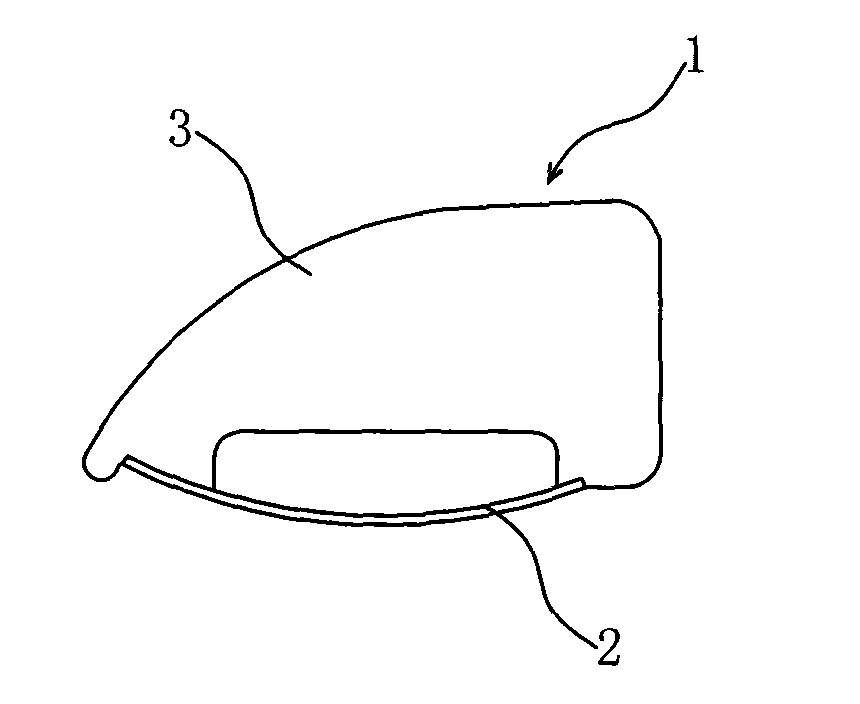

[0020] Example 1: see figure 2 , 3 , The vehicle mirror 1 described in this embodiment is suitable to be installed outside the vehicle body on one side of the cab, and includes a housing 3 and a lens 2 installed in the housing. The housing 3 is mounted on the mirror base of the vehicle body When up, it can rotate relative to the body. The contribution of the present invention is characterized in that the lens 2 is an aspherical convex lens with a one-piece structure. The structure of the lens can be understood as follows: the direction of the lens from the side of the vehicle body to the outside of the vehicle is regarded as the length direction of the lens, namely figure 1 As shown in the X axis direction, the Y axis direction is the width direction of the lens. If the lens is cut along the Y axis, the width direction of the lens, the longitudinal section of the lens can be regarded as a circular arc. The curvature of the arc of the initial longitudinal section is 0.2, (it can ...

Embodiment 2

[0022] Example 2: see Figure 4 , 5 The vehicle mirror 1'described in this embodiment is suitable for being installed outside the vehicle body on the side of the passenger cabin, and it also includes a housing and a lens installed in the housing, and the housing is mounted on the vehicle’s mirror base When up, it can rotate relative to the body. The structure of the lens and the method of forming the lens in this embodiment are the same as those in the embodiment, except that the curvature of the arc of the lens from the vehicle body side to the outer longitudinal section of the vehicle is gradually increased from 0.2 to 1.2.

[0023] If you look at the left and right side mirrors from the driver’s position, the lenses on both sides of the body should have different curvatures due to the distance and angle from the mirror 1'. For the mirror 1', if it is on the side of the body If the curvature of the longitudinal section of the lens is less than 0.2, the light from the headlights ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com