Fully sealed plate vane-type purification filter

A purification filter and fully-sealed technology, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve problems such as unguaranteed product quality, non-compliance with hygienic operation standards, and impact on environmental sanitation, etc., to achieve Improve the labor intensity, improve the working environment, and solve the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

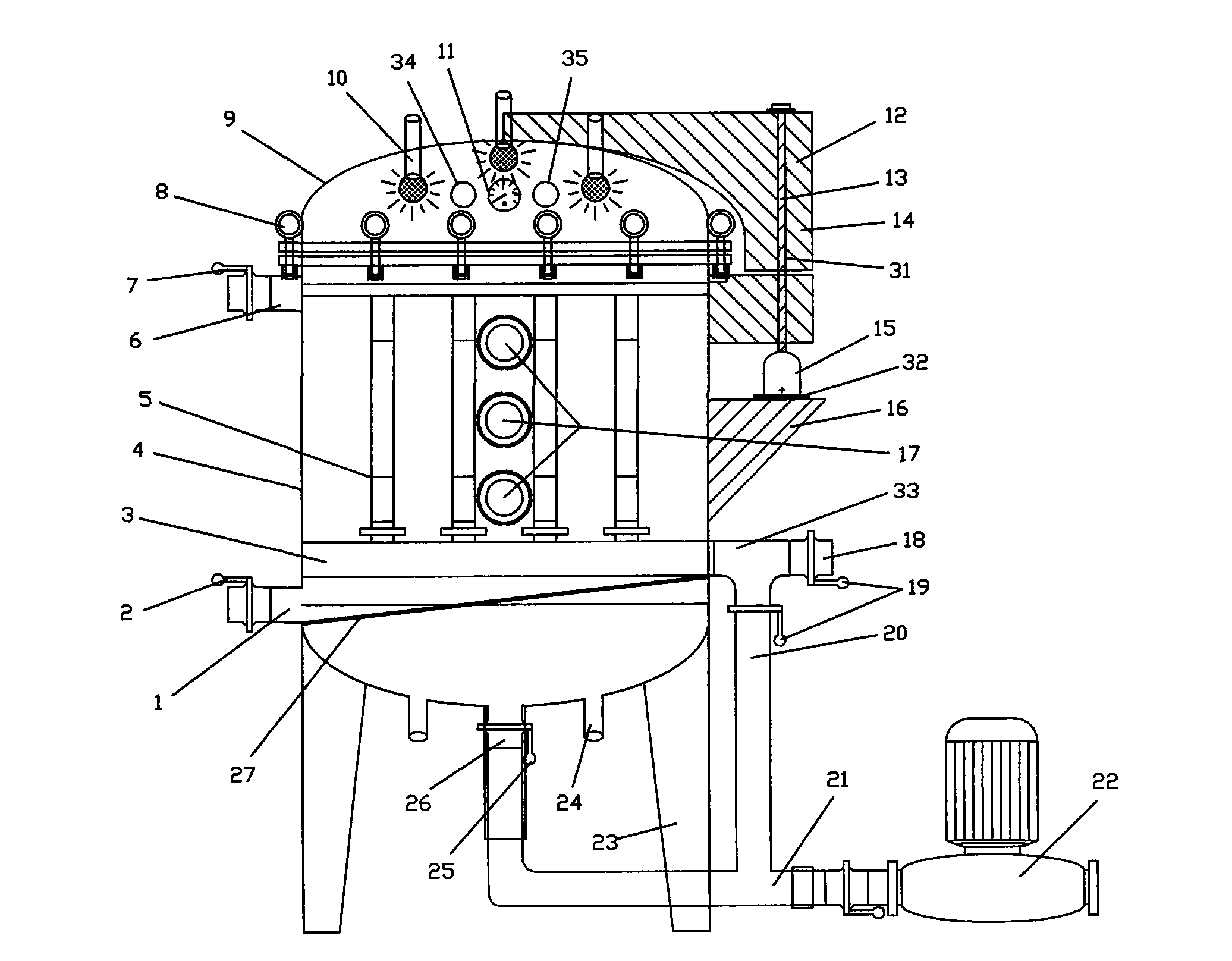

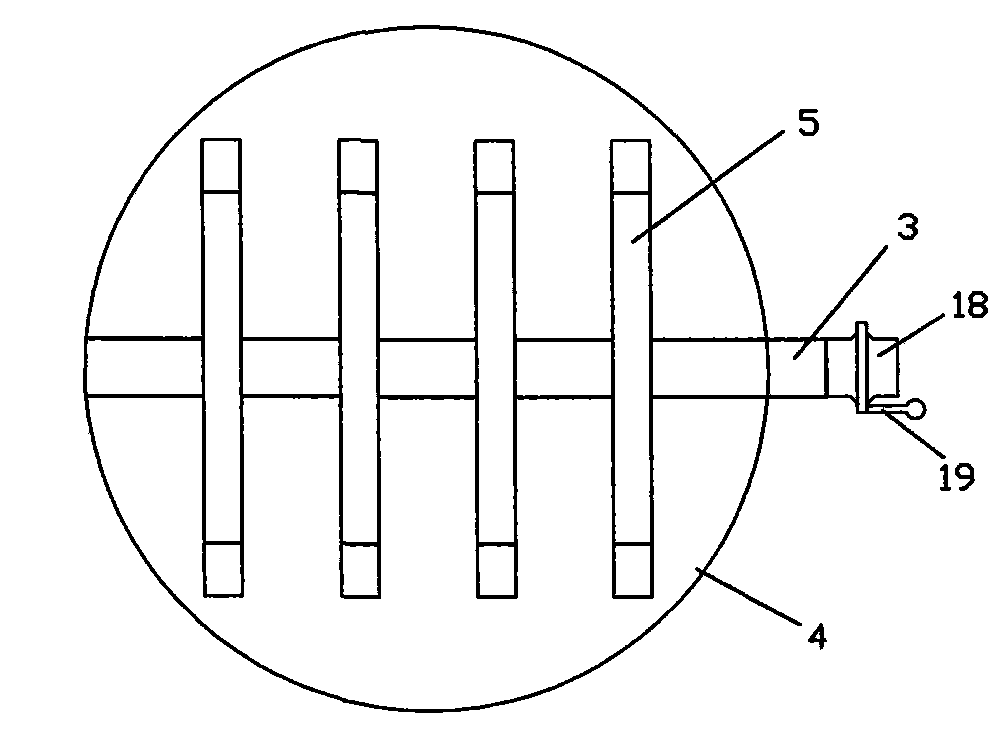

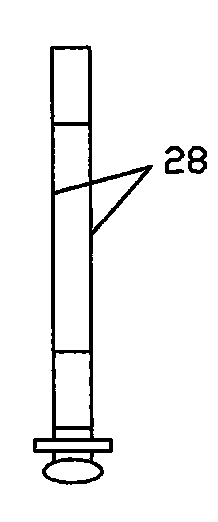

[0021] see figure 1 , the present invention adopts stainless steel plate to make cylindrical tank body 4 and matching upper cover 9, both adopt flange structure and a plurality of bolts 8 to fasten and connect, the upper end of tank body 4 is provided with feeding pipe 6 equipped with Valve 7, the bottom of tank body 4 is provided with discharge pipe 26 and is equipped with valve 25. Especially: in tank body 4, be higher than tank bottom surface 220mm left and right sides and be installed with the filtering sieve plate 27 of oblique arrangement; There is valve 2. Above the filter sieve plate 27 is provided with a collection and discharge pipe 3 that traverses, and the collection and discharge pipe 3 stretches out of the tank and a tee 33 is installed, and the discharge pipe 20 and the cleaning pipe 18 (each equipped valve 19) are connected externally. Four plate-shaped filter covers 17 are installed side by side above the collecting pipe, and the specific structure of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com