Discharge lamp comprising a discharge vessel and an electrode frame

A discharge vessel and electrode holder technology, which is applied in the field of discharge lamps, can solve the problems of high cost and troublesome manufacturing, and achieve the effect of easy handling and cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

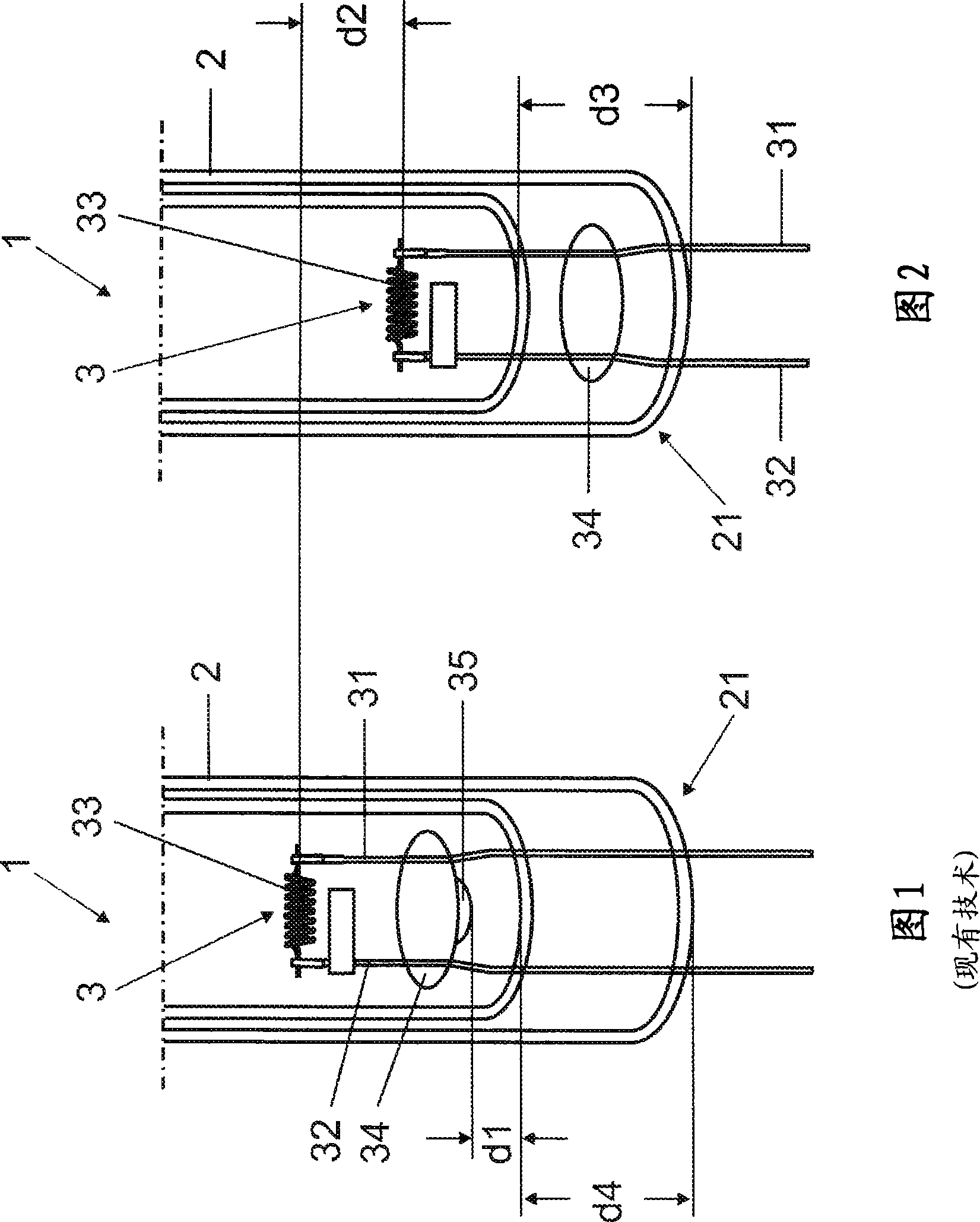

[0021] In the figures, identical or functionally identical elements are provided with the same reference signs.

[0022] The discharge lamp 1 embodied as a low-pressure discharge lamp comprises a tubular discharge vessel 2 having a lower end region 21 which is extruded. The electrode holder 3 protrudes partially into the discharge vessel 2 and comprises two wire-shaped electrode holders 31 and 32 . A filament 33 is arranged as an electrode on the front ends of the two electrode holders 31 and 32 which are arranged in the discharge vessel 2 . The glass bead 34 extends between the two electrode holders 31 and 32 and is pressed completely into the end region 21 in the exemplary embodiment. The glass material of the end region 21 differs from the glass material of the glass beads 34 in this exemplary embodiment. In particular, the two glass materials are constructed such that their coefficients of thermal expansion differ from one another, so that when a temperature gradient occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com