Plastic wave mould strip exchanger core of new blower

A wave type, new fan technology, applied in the field of fan exchange cores and fresh fan exchange cores, can solve the problems of not improving conduction efficiency, low heat and mass exchange efficiency, reducing heat and mass exchange area, etc., to improve heat and mass exchange efficiency. , Increase the time of heat and mass exchange, the effect of strong and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

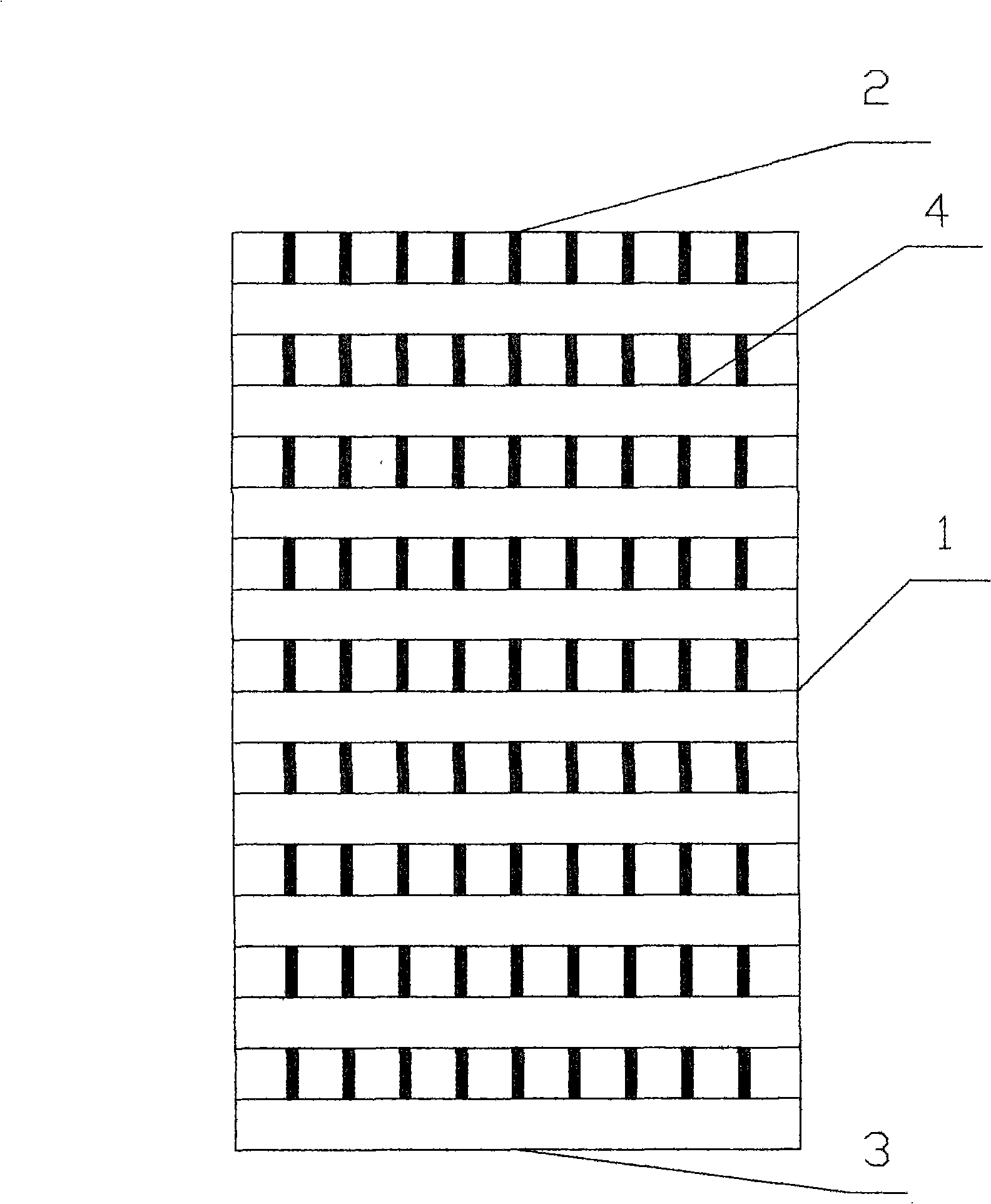

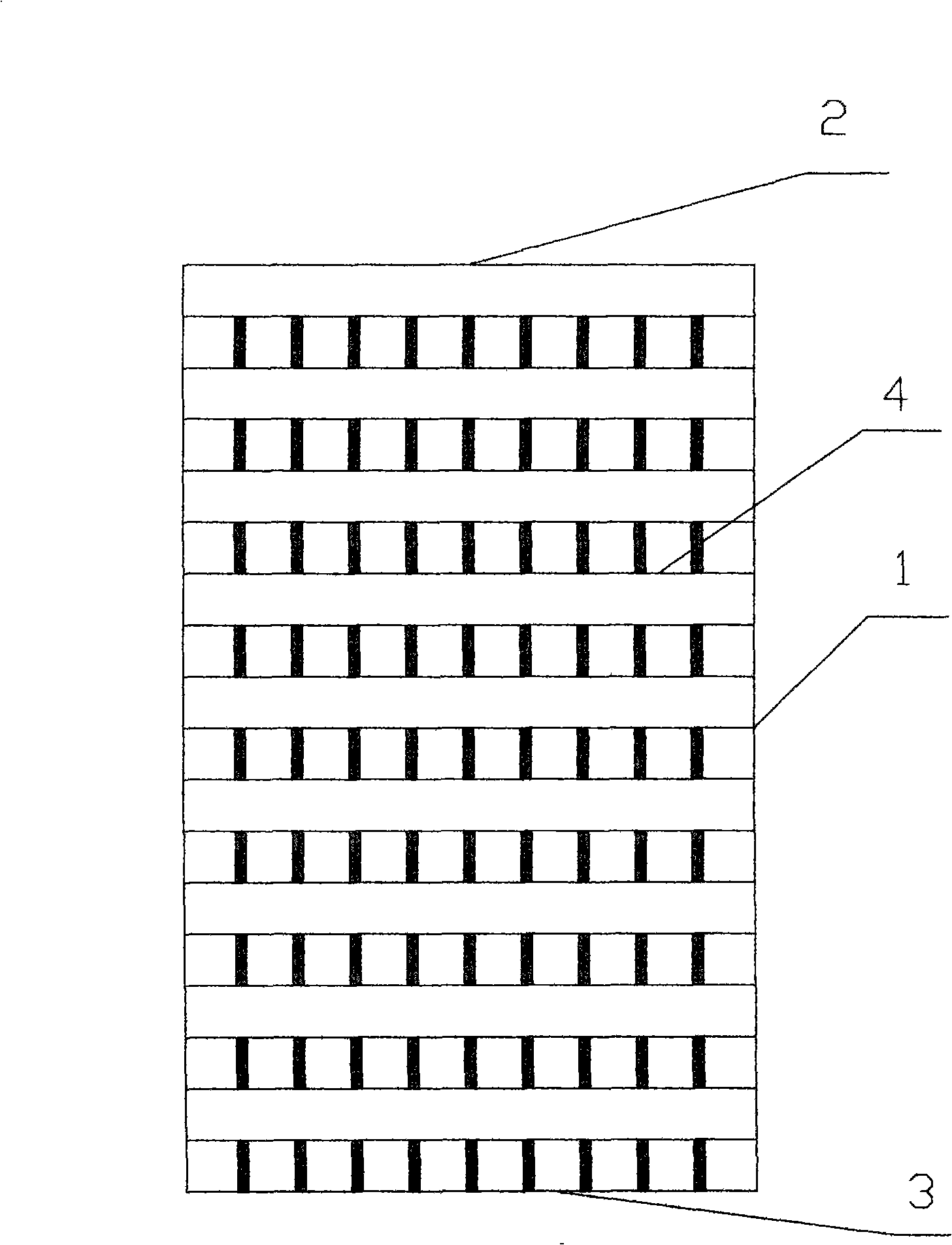

[0042] As shown in Figure 1 (A), (B), (C), a new fan switch core for adopting plastic wave-shaped strips, including a cubic cylinder new fan frame 1, front and rear covers 2, 3, plastic waves Shaped strip frame group and heat and mass exchange material group. The heat and mass exchange material is in the form of a paper sheet. Between the new fan frame 1 and the front and rear covers 2, 3, the plastic wave-shaped strip frame 4 and the heat and mass exchange material (not shown in the figure, Same below) Interval setting. As shown in Figure 2 (A) and (B), the plastic wave-shaped strip frame 4 is composed of a frame 41 and equidistantly arranged wave-shaped strips 42. Since the plastic wave-shaped strip frame 4 with a smooth surface is used as the air channel, the It has a great effect on reducing the air resistance of the movement. The profile bars 42 of adjacent plastic wave-shaped bar frames 4 are placed perpendicular to each other. The frame profiles 42 are flat plastic wave...

Embodiment 2

[0053] As shown in Figure 1 (A), (B), (C), a new fan switch core for adopting plastic wave-shaped strips, including a cubic cylinder new fan frame 1, front and rear covers 2, 3, plastic waves The profiled strip frame group and the sheet-like heat and mass exchange material group are arranged between the fresh air blower frame 1 and the front and rear end covers 2, 3, and the plastic wave-shaped strip frame 4 and the heat and mass exchange material (not shown in the figure) are arranged at intervals. As shown in Figure 3(A) and (B), the plastic wave-shaped bar frame 4 is composed of a frame 41 and equidistantly arranged bars 42. Because the plastic wave-shaped bar frame 4 with a smooth surface is used as the air channel, it is reduced The air resistance of the movement has a great effect. The profile bars 42 of adjacent plastic wave-shaped bar frames 4 are placed perpendicular to each other. The frame profiles 42 are flat plastic wave-shaped strips 42 in the same shape and equid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com