Near-suction type smoke purifier

An oil fume purifier and near-suction technology, applied in the direction of oil fume removal, heating methods, chemical instruments and methods, etc., can solve the problems of flue gas backflow, poor smoke exhaust, air pollution, etc., and improve the purification efficiency and structure. Small and compact, wind-efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment, the near-suction fume purification machine of the present invention is described in further detail:

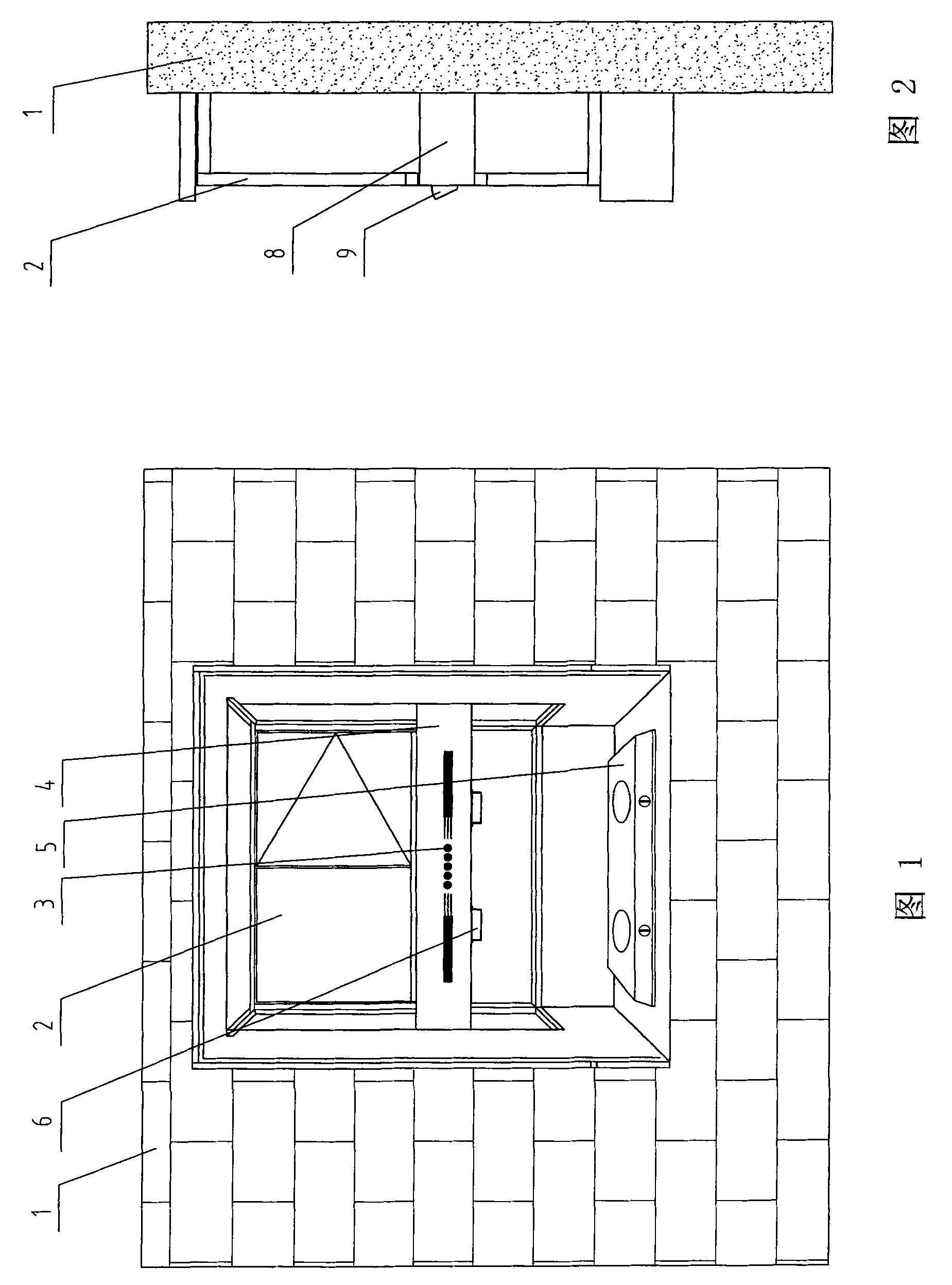

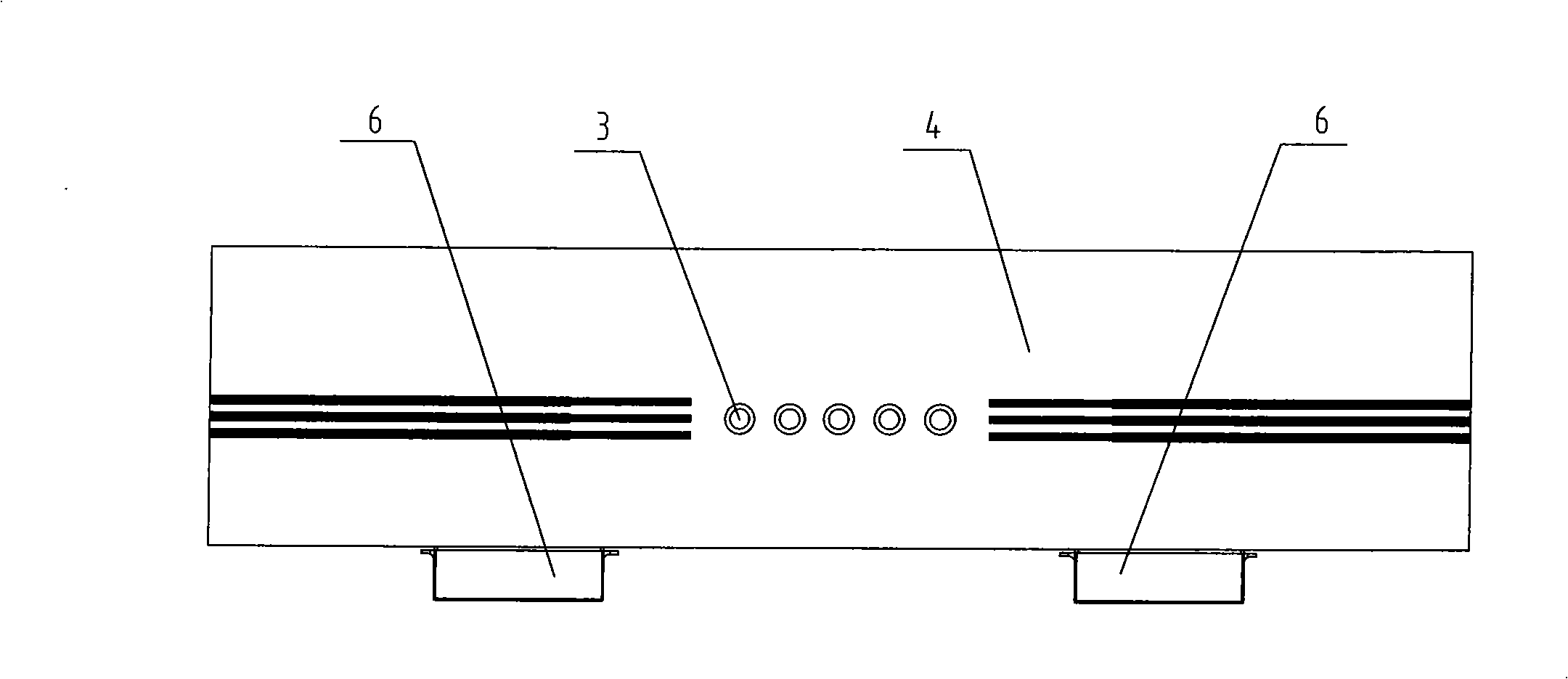

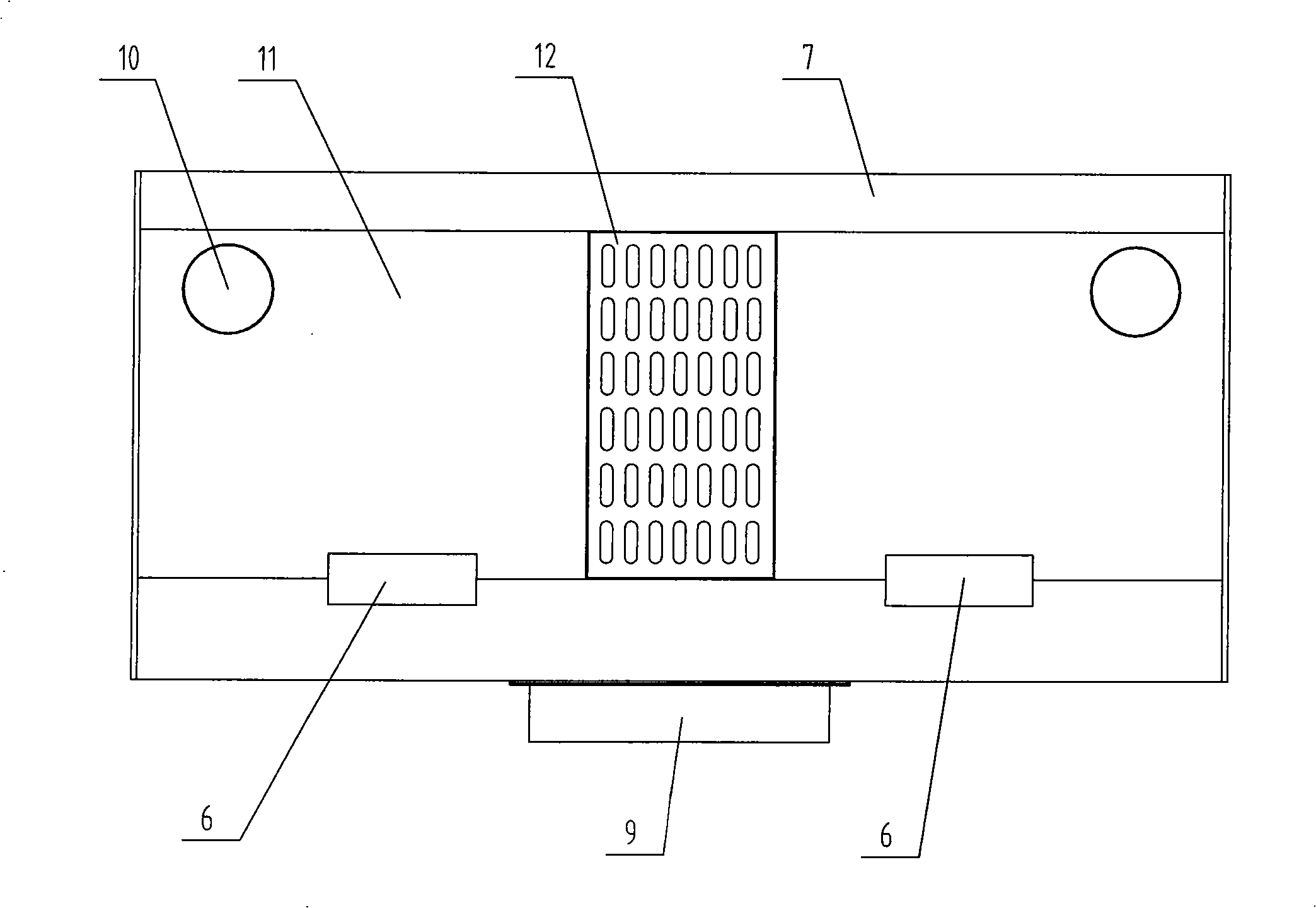

[0028] The near-absorption type oil fume purifier shown in the figure is installed in the platform window 2 on the kitchen wall 1, and is positioned at the top 550mm of the gas stove 5. It has a flat rectangular parallelepiped casing 7, and the casing 7 is an assembled structure of profiles and plates that is convenient for mass production and quick assembly. It consists of the first profile 20 arranged at the front upper corner, the front lower corner and the rear upper corner, and the second profile 21 arranged at the rear lower corner to form a flat rectangular parallelepiped frame. The second profile 21 is formed with an oil collection tank 18, and The panel 4, backboard 17, side board 8 and top board 14 of 7 are respectively embedded on the corresponding position of this framework. A duplex vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com