Injection valves for direct injection

An injection valve, direct technology, applied in the direction of fuel injection pump, fuel injection device, special fuel injection device, etc., can solve the problem of insufficient flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

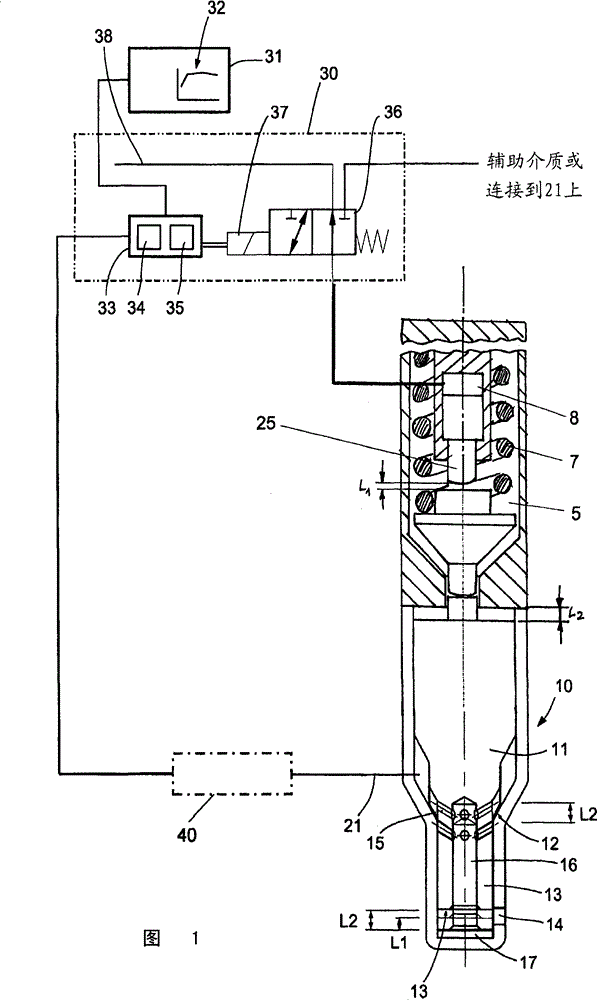

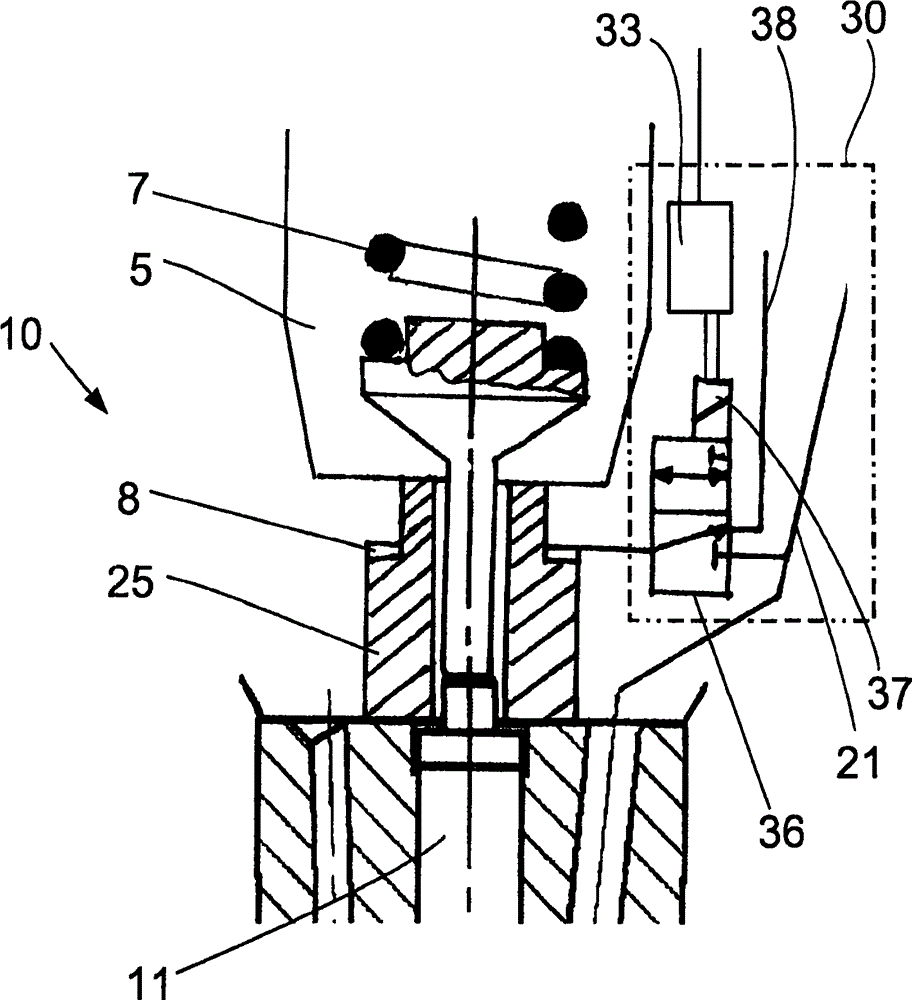

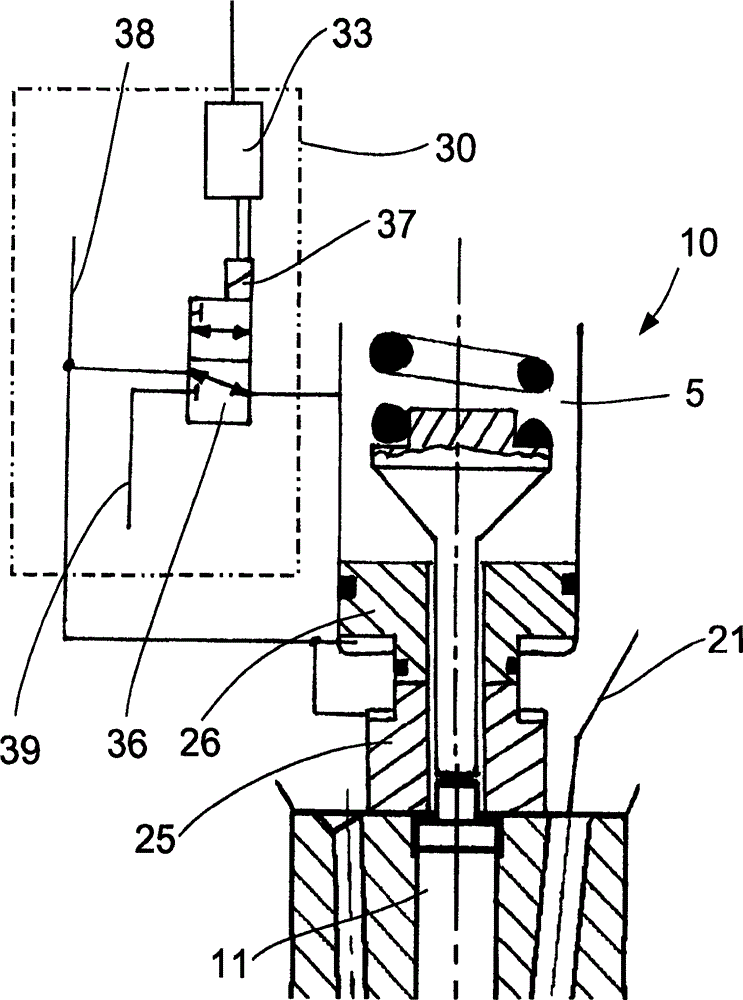

[0030] figure 1 An injector with a control device according to one embodiment of the invention is shown for the direct injection of fuel into a combustion chamber of a large diesel engine. Injection valve 10 has an axially displaceable valve needle 11 which can be mounted sealingly on a needle seat 12 . The valve needle 11 includes a needle tip 13 which completely covers the spray opening 14 in the region of the needle seat 12 when the valve needle 11 is in the position shown. In this position, fuel from injection pressure and volume flow source 40 cannot flow into injection chamber 17 of injection valve 10 via fuel line 21 .

[0031] Injection pressure and volume flow source 40 is only temporarily connected to fuel line 21 via a suitable switching mechanism.

[0032] If the valve needle 11 is raised from the needle seat 12 , the connection of the fuel line 21 to the injection chamber 17 of the injection valve 10 is opened. The fuel delivered through the fuel line 21 then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com