Cast-in-place lightweight inner partition wall

A kind of inner partition wall and lightweight technology, applied in the direction of walls, sound insulation, building components, etc., can solve the problem that the production scale is too small to meet the use of large buildings, and achieve the effect of improving the sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

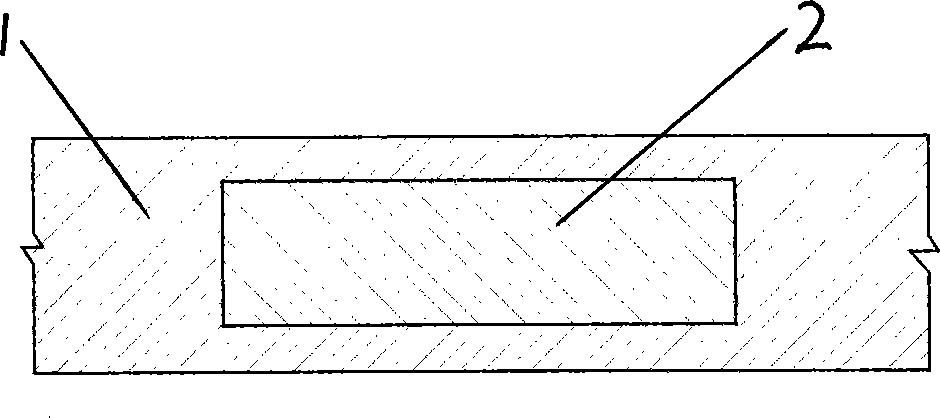

[0035] The cast-in-place lightweight inner partition wall in this example, such as Figure 1 and Figure II As shown, it is characterized in that the cement-based wall 1 made by the cast-in-place method is inlaid with a lightweight thermal insulation board 2, and the lightweight thermal insulation board 2 is a polystyrene foam board. The cast-in-place method is to fix a row of templates 8 on one side of the partition wall to be poured, and then fix the light heat insulation board 2 at the middle position of the partition wall to be poured, and the two sides of the light heat insulation board 2, A wall thickness control member 5 is provided, and then a row of formwork 8 is fixed on the other side of the partition wall to be poured, and the terminals of the formwork 8 are connected to the existing wall and the L-shaped member 6 respectively (such as Figure ten 4), in the middle of the template 8, a wall thickness control member 9 is arranged, and self-leveling inorganic gelling...

Embodiment 2

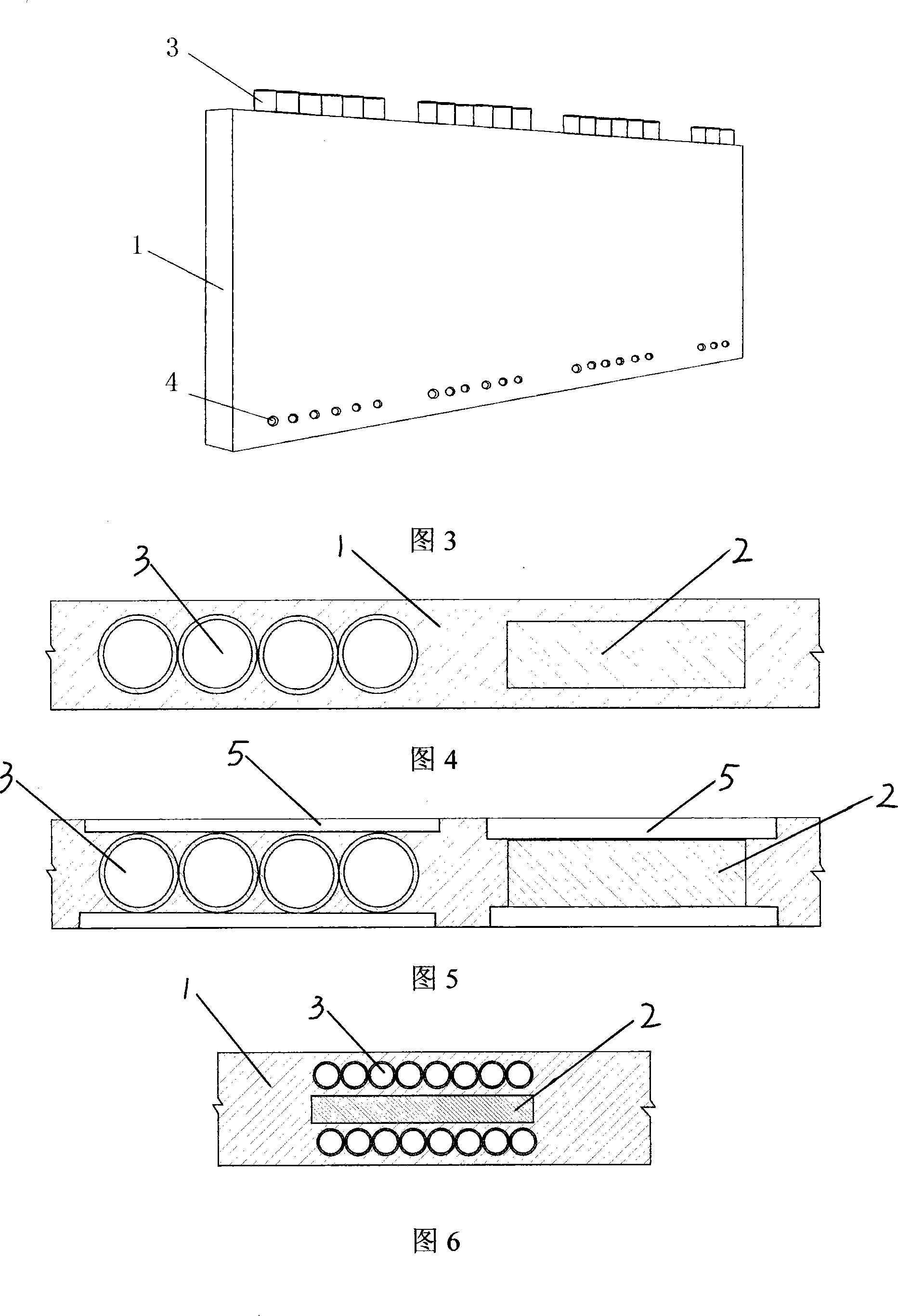

[0038] The cast-in-place lightweight inner partition wall in this example, such as Figure three and Figure four As shown, it is characterized in that the gypsum-based wall 1 made by the cast-in-place method is inlaid with a lightweight thermal insulation board 2 and a hollow cylinder 3, the lightweight thermal insulation board 2 is a polystyrene foam board, and the hollow The cylinder body 3 is a hollow paper cylinder. Before the wall body is dry, the lower part of the hollow cylinder body 3 is provided with a ventilating and dehumidifying hole 4 , and the ventilating and dehumidifying hole 4 passes through the wall body 1 . Such as Figure ten As shown in 6, the cast-in-place method is to fix a row of templates 8 on one side of the partition wall to be poured, and then fix the lightweight thermal insulation board 2 and the hollow cylinder 3 in sections in the middle of the partition wall to be poured, Both sides of the lightweight thermal insulation board 2 and the hollo...

Embodiment 3

[0041] The cast-in-place lightweight inner partition wall in this example is characterized in that the gypsum-based wall 1 made by the cast-in-place method is inlaid with a lightweight thermal insulation board 2, and the lightweight thermal insulation board 2 is a lightweight gypsum board . The cast-in-place method is to fix a row of templates 8 on one side of the partition wall to be poured, and then fix the light heat insulation board 2 at the middle position of the partition wall to be poured, and the two sides of the light heat insulation board 2, A wall thickness control member 5 is provided, and then a row of formwork 8 is fixed on the other side of the partition wall to be poured, and the terminals of the formwork 8 are connected to the existing wall and the L-shaped member 6 respectively (such as Figure ten 4), in the middle of the template 8, a wall thickness control member 9 is arranged, and self-leveling inorganic gelling slurry is poured between the two rows of te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com