Glass fiber reinforced polyester mineral composite material and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of composite materials, can solve the problems that are difficult to improve the dynamic and static performance and thermal stability of machine tools, achieve excellent damping and vibration reduction performance, improve mechanical properties, and improve damping and vibration reduction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

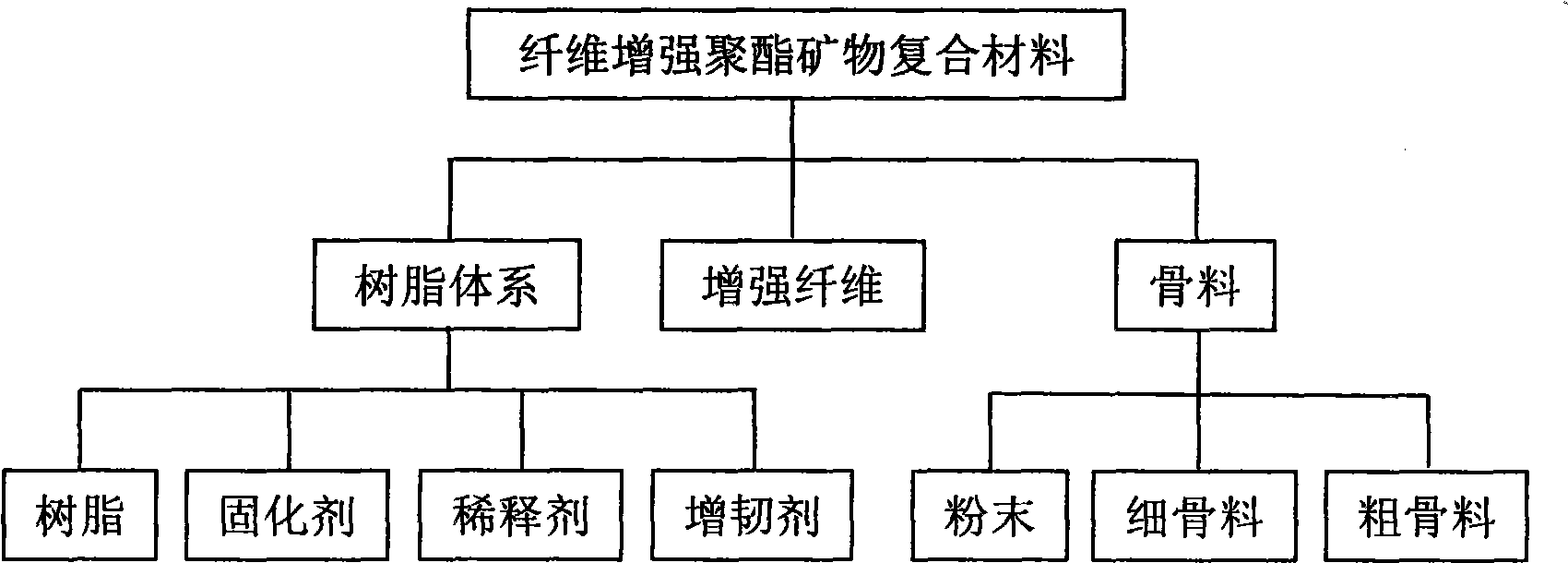

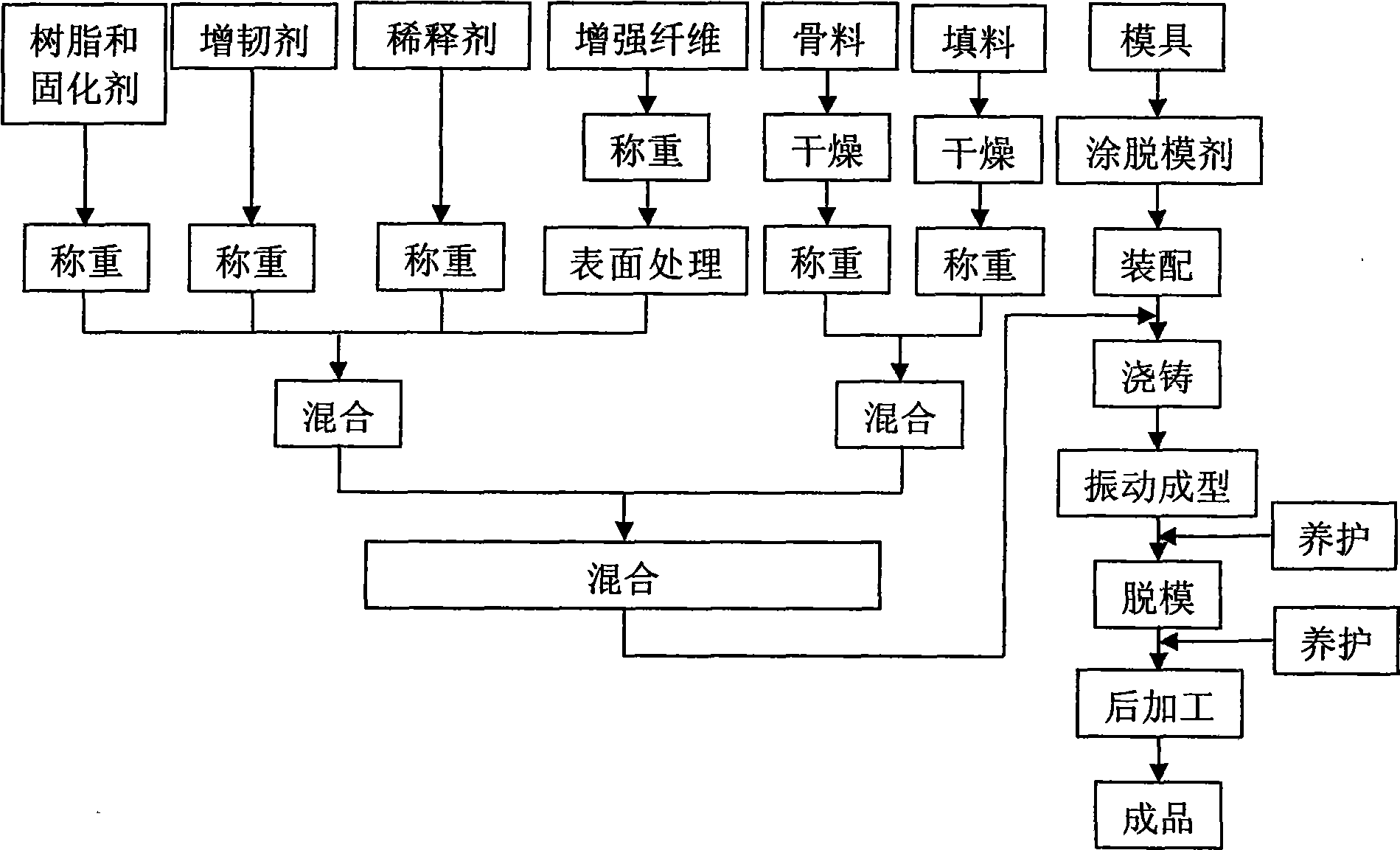

[0024] The preparation method of the glass fiber reinforced polyester mineral composite material includes the following steps (such as figure 2 ):

[0025] a) Sieving granite particles or sand particles into 6 levels according to the particle size range: 0.1mm~0.6mm, 0.6mm~2mm, 2mm~3.5mm, 3.5mm~5mm, 5mm~7mm, 7mm~10mm , Clean and dry the granular aggregates of different particle size grades, and then weigh them according to a certain mass ratio according to the different particle size grades and mix them evenly; b) Weigh the glass fibers and use the silane coupling agent soaking method to surface treat the glass fibers; c) Weigh the liquid synthetic resin, diluent, toughening agent and curing agent and mix them into a uniform resin system, add the surface-treated glass fiber to the uniformly mixed resin system, and stir to make it evenly distributed; d) mix The uniform solid particle aggregate is added to the homogeneous mixture of the resin system and glass fiber, and continues to...

Embodiment 1

[0027] Aggregate: 8000g natural granite particles, of which:

[0028] 0.1mm~0.6mm: 1040g, accounting for 13%

[0029] 0.6mm~2mm: 1360g, accounting for 17%

[0030] 2mm~3.5mm: 1200g, accounting for 15%

[0031] 3.5mm~5mm: 1120g, accounting for 14%

[0032] 5mm~7mm: 1360g, accounting for 17%

[0033] 7mm~10mm: 1920g, accounting for 24%

[0034] Adhesive base 975g, of which:

[0035] Epoxy resin 660g

[0036] Curing agent ethylene diamine 200g

[0037] Thinner acetone 55g

[0038] Toughening agent dibutyl phthalate 60g

[0039] Glass fiber 25g

[0040] The obtained glass fiber reinforced polyester mineral composite material has a compressive strength of 97.68MPa and a damping ratio of 0.231.

Embodiment 2

[0042] Aggregate: 50kg of natural granite particles, of which:

[0043] 0.1mm~0.6mm: 7kg, accounting for 14%

[0044] 0.6mm~2mm: 8kg, accounting for 16%

[0045] 2mm~3.5mm: 7.5kg, accounting for 15%

[0046] 3.5mm~5mm: 7kg, accounting for 14%

[0047] 5mm~7mm: 9kg, accounting for 18%

[0048] 7mm~10mm: 11.5kg, accounting for 23%

[0049] Adhesive base 7.8kg, of which:

[0050] Epoxy resin 5.5kg

[0051] Curing agent ethylenediamine 1.6kg

[0052] Thinner acetone 0.3kg

[0053] Toughening agent dibutyl phthalate 0.4kg

[0054] Glass fiber 0.2kg

[0055] The obtained glass fiber reinforced polyester mineral composite material has a compressive strength of 103.51MPa and a damping ratio of 0.207.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com