A method for manufacturing electroplating diamond wire saw

A technology of electroplating diamonds and manufacturing methods, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of low production efficiency and high cost, and achieve the effects of improving production efficiency, increasing current density, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment relates to a manufacturing method of an electroplated diamond wire saw for cutting semiconductor materials (such as silicon crystals), optoelectronic materials, piezoelectric crystals, magnetic materials, and the like.

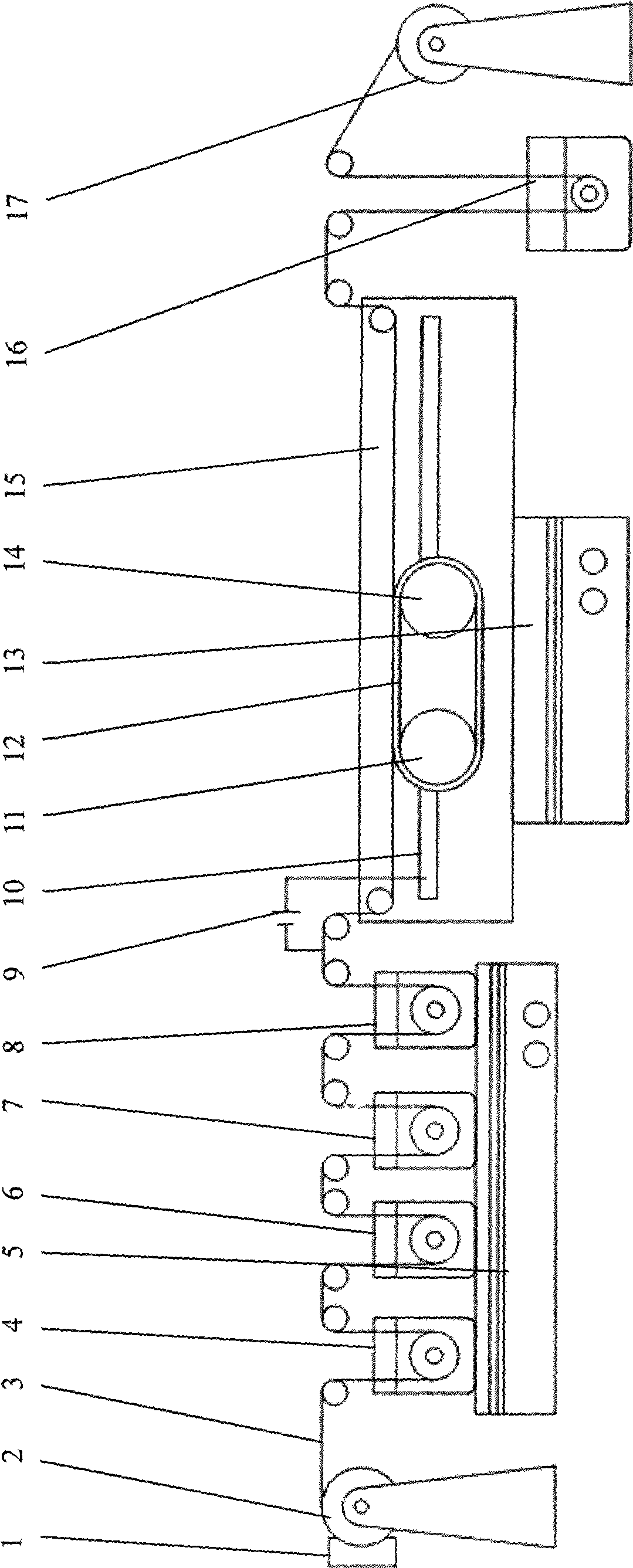

[0024] Refer to attached figure 1 A method for manufacturing an electroplated diamond wire saw, the method comprising the following steps:

[0025] (1) The metal wire 3 is a piano wire with a diameter of φ0.11mm, and the length is 1000m. Wind the metal wire on the pay-off reel 2 before use.

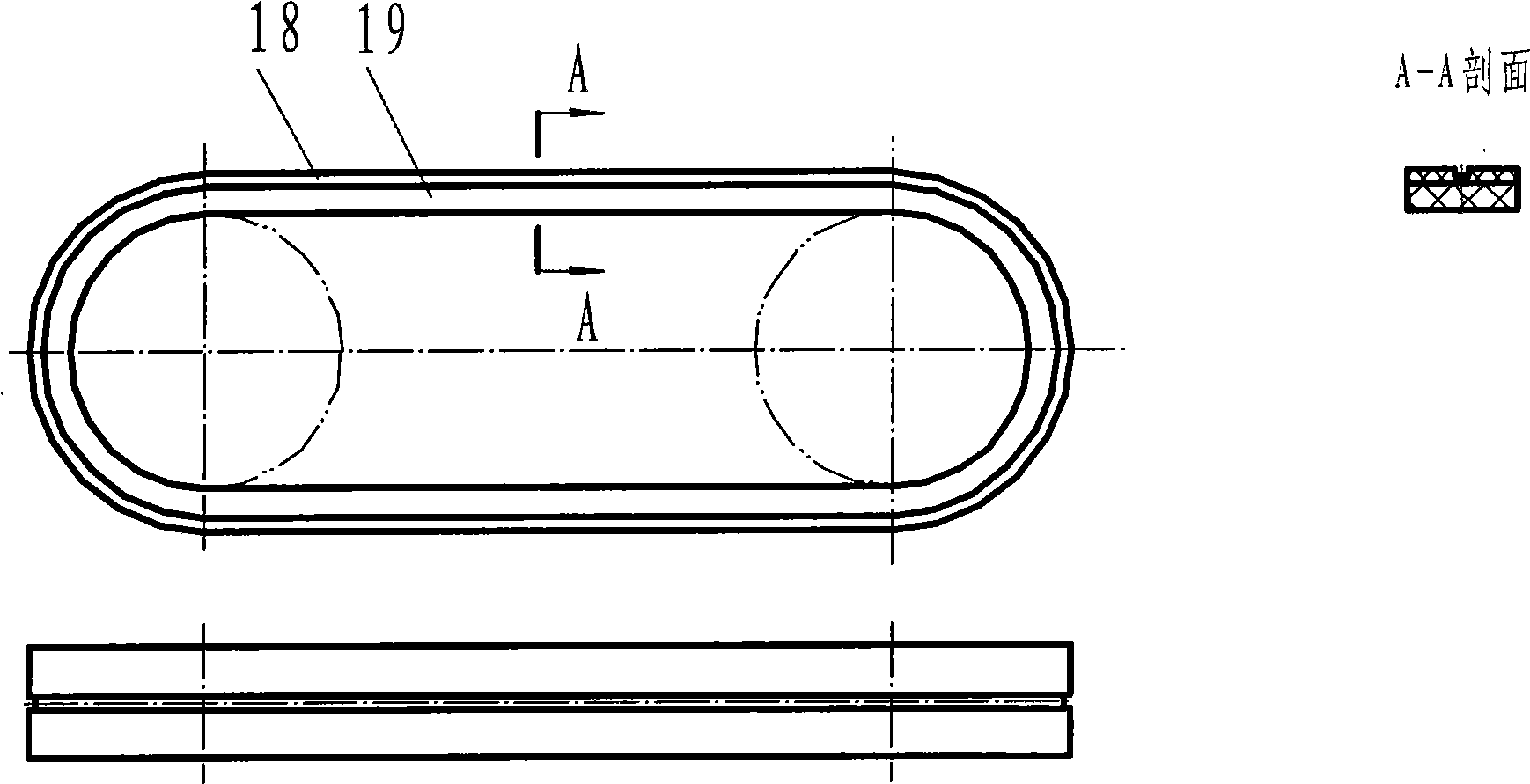

[0026] (2) The other section of the metal wire wound on the pay-off wheel 2 passes through the alkali washing tank 4, the cleaning tank 6, the pickling tank 7, the cleaning tank 8, the electroplating tank 15, and the cleaning tank 16, and is fixed on the take-up wheel 17 superior. When the metal wire 3 passes through the electroplating tank 15, it is placed in the groove of the endless hair band 12. The loader 1 on the pay-off reel 2 makes the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com