125 motorcycle engine starting gear cold extrusion forming method and dies thereof

A technology for engine start-up and extrusion dies, which is applied in the direction of metal extrusion dies, etc., can solve the problems of not being able to adapt to the processing of specific gear products, and achieve the effects of good product quality consistency, high work efficiency, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

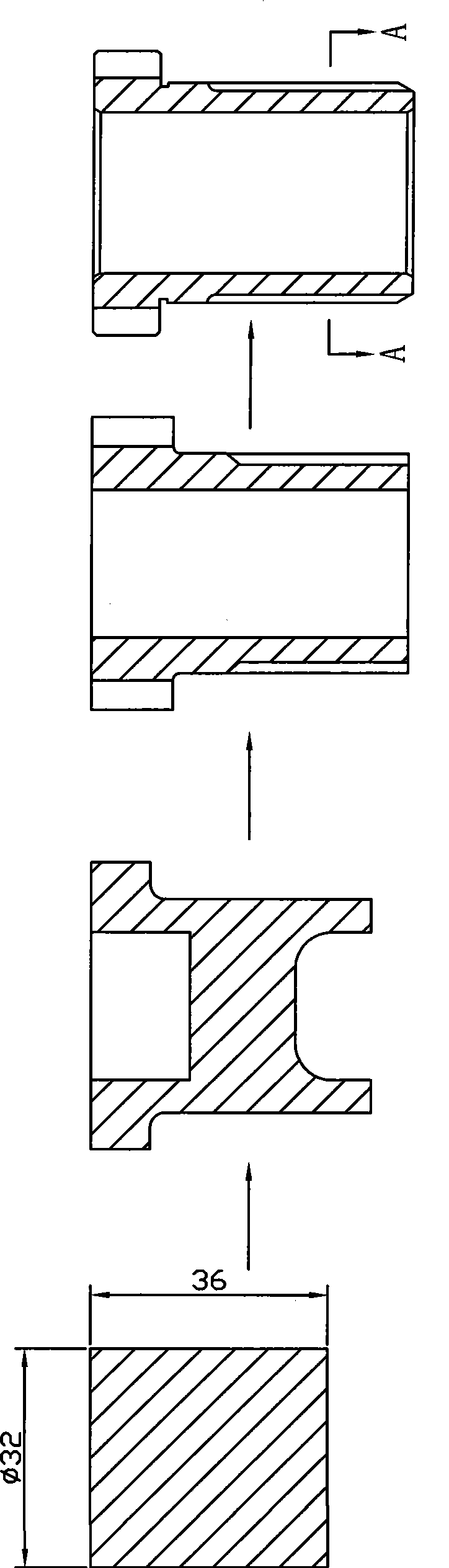

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , a kind of 125 motorcycle engine starting gear cold extrusion molding method, comprises the following steps:

[0037] a), blanking

[0038] Cut a metal bar with a specified diameter to a specified height to form a billet;

[0039] b), cold extrusion starting gear blank

[0040] see figure 1, put the blank on the middle mold cavity of the blank extrusion mold, start the hydraulic piston on the hydraulic press, the pressure head of the blank extrusion mold goes down, and press the blank in step a into the middle mold cavity of the blank extrusion mold In the process, the blank is extruded into the upper tooth blank and the lower keyway blank of the 125 motorcycle engine starting gear in the middle mold cavity, and at the same time, the cylindrical convex head at the lower end of the indenter presses the upper end of the blank out of the upper center blind hole, The lower end of the billet is pressed out of the lower ...

Embodiment 2

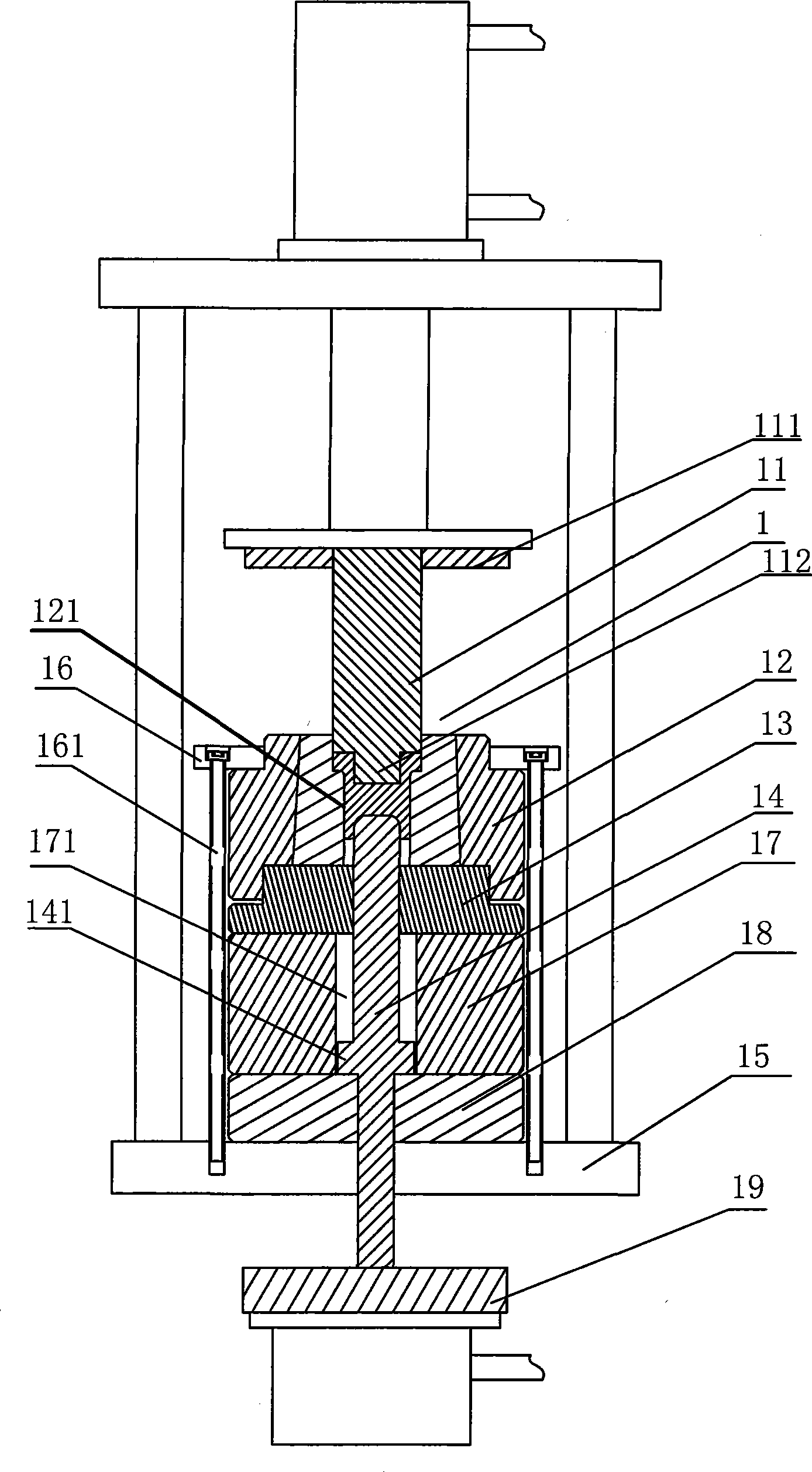

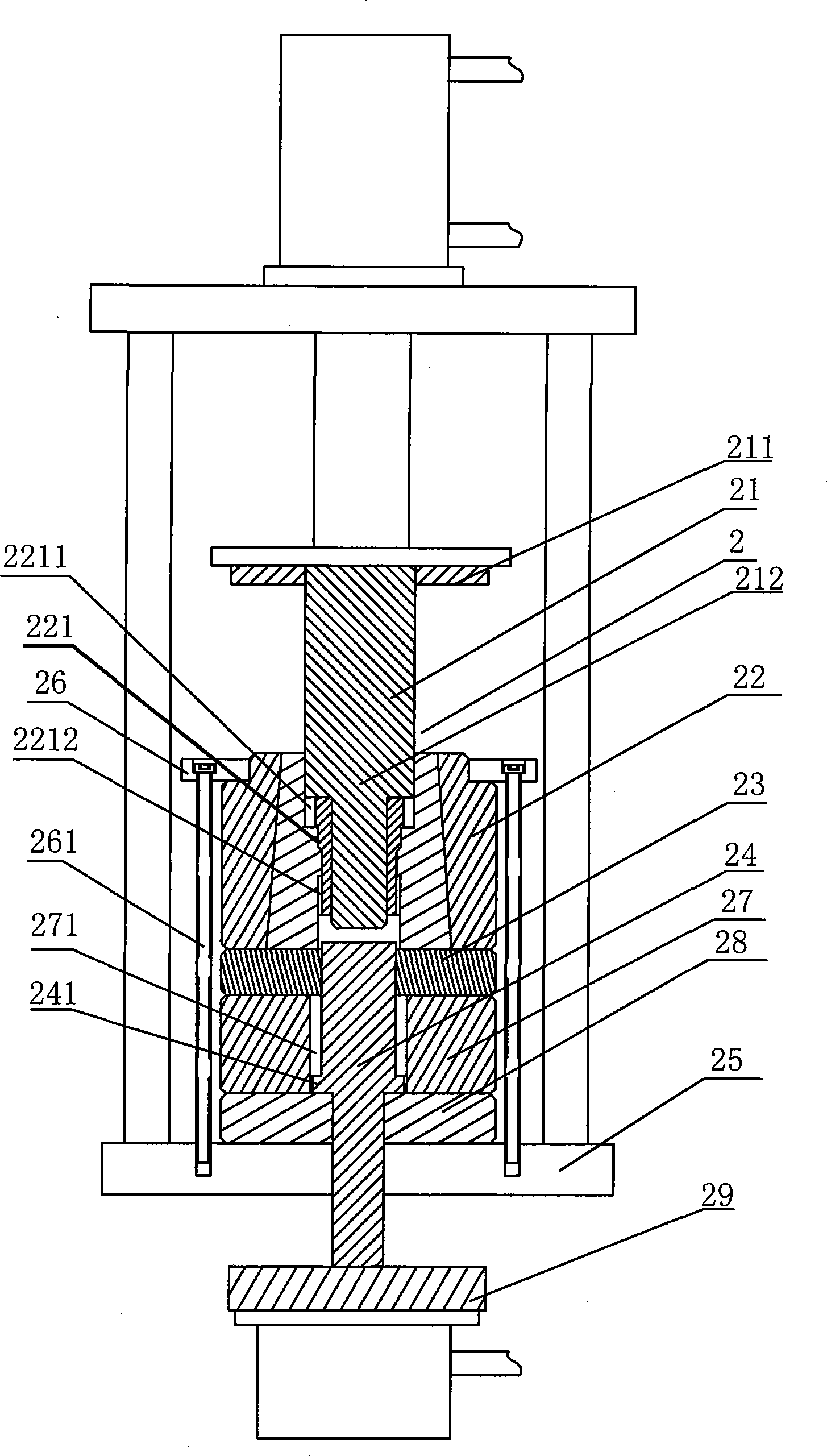

[0047] see figure 1 , figure 2 , a cold extrusion device for realizing the above-mentioned 125 motorcycle engine starting gear cold extrusion molding method, including a hydraulic press with upper and lower oil cylinders and a die, characterized in that: the die includes a blank extrusion die 1 and teeth and keyways The extrusion die 2, the blank extrusion die 1 and the tooth and keyway extrusion die 2 are respectively installed on a hydraulic press with upper and lower oil cylinders;

[0048] see figure 1 , the blank extrusion die 1 mold includes a cylindrical pressure head 11, a middle mold 12, a lower mold 13, and a push plate 14. The flange 111 of the pressure head 11 is fixedly connected with the piston of the upper cylinder of the hydraulic press, and the lower end of the pressure head 11 A cylindrical protruding head 112 is provided, the diameter of the indenter 11 is the same as that of the tooth blank on the upper part of the gear blank, and the diameter of the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com