Pressure-compensation variable-cross-section special shaped spray head

A technology of pressure compensation and variable cross-section, which is applied in the direction of spraying devices and spraying devices, which can solve the problems of reduced spraying uniformity of sprinklers, unstable operation of water pumps, and decreased spraying uniformity, so as to achieve good spraying uniformity and uniform spraying The effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

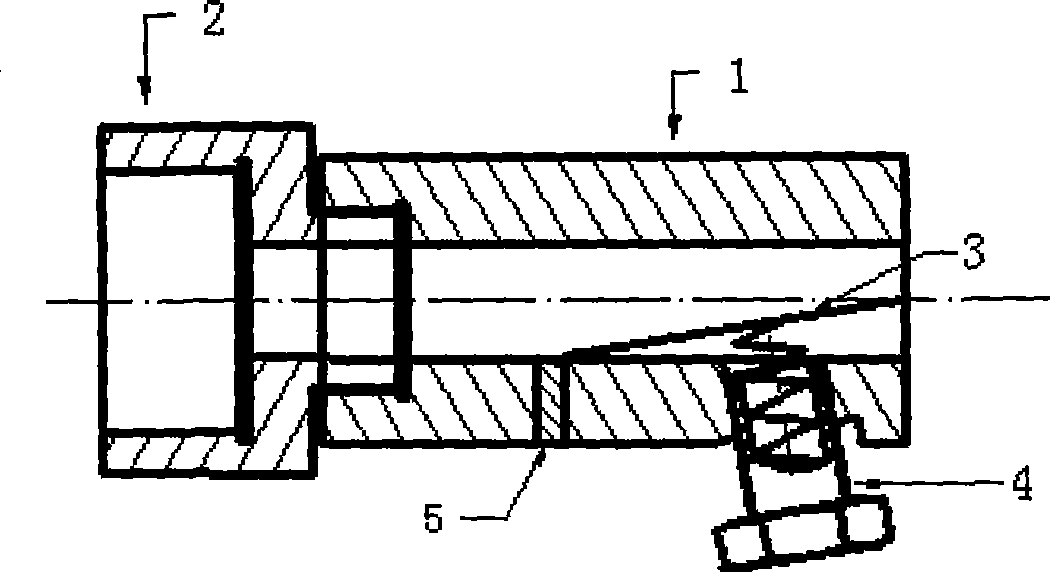

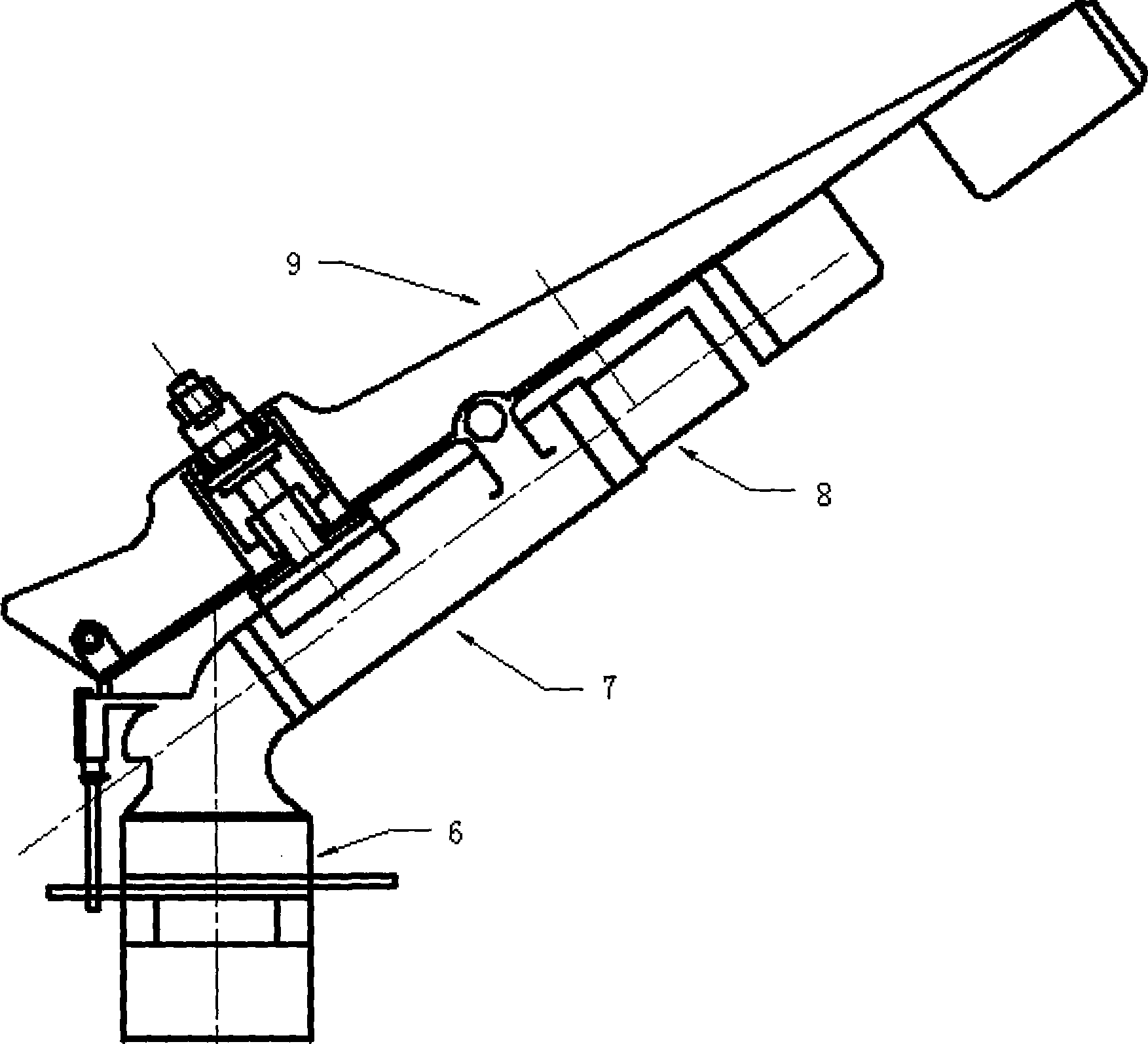

[0011] The pressure-compensated variable-section special-shaped nozzle is composed of four parts: a rotary sealing mechanism 6, a flow channel 7, a pressure compensation mechanism 8, and a rocker mechanism 9. The key part is the pressure compensation mechanism 8. figure 1 The water baffle 3 shown is fixed in the groove on the nozzle wall by the fastener 5 by means of the empennage. A section of iron wire is welded on the water retaining plate 3 to fix the spring 4, and it is fixed in the nozzle flow channel in a slope shape. figure 1 The shown spring 4 is fixed in a hollow bolt, and is installed near the outlet of the nozzle, and the uppermost end of the spring 4 is fixed on the water retaining plate 3, so that the spring 4 is positioned. The resultant force of the water flow force and the elastic force of the spring 4 makes the water retaining plate 3 move up and down, and the spring mechanism can well control the water retaining plate 3 to move and reset.

[0012] The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com