Presser inspection well cover

A technology of inspection well cover and pressure plate, which is applied in the field of inspection well cover, can solve the problems of poor affinity and insufficient thickness of the road surface, etc., and achieve the effects of prolonging the service life, saving repair costs, saving fuel costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Such as figure 1 , 2 , 3, 5, 6, 7, and 8.

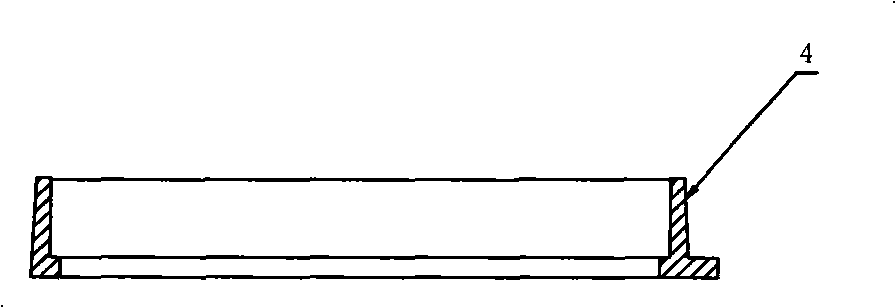

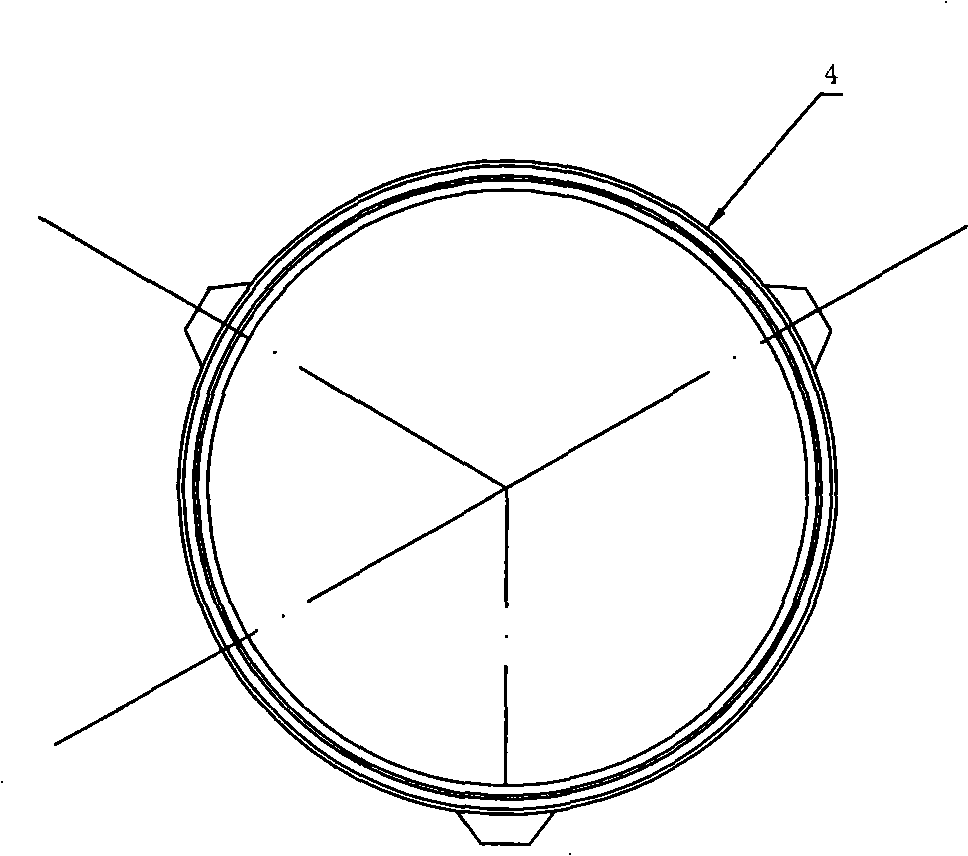

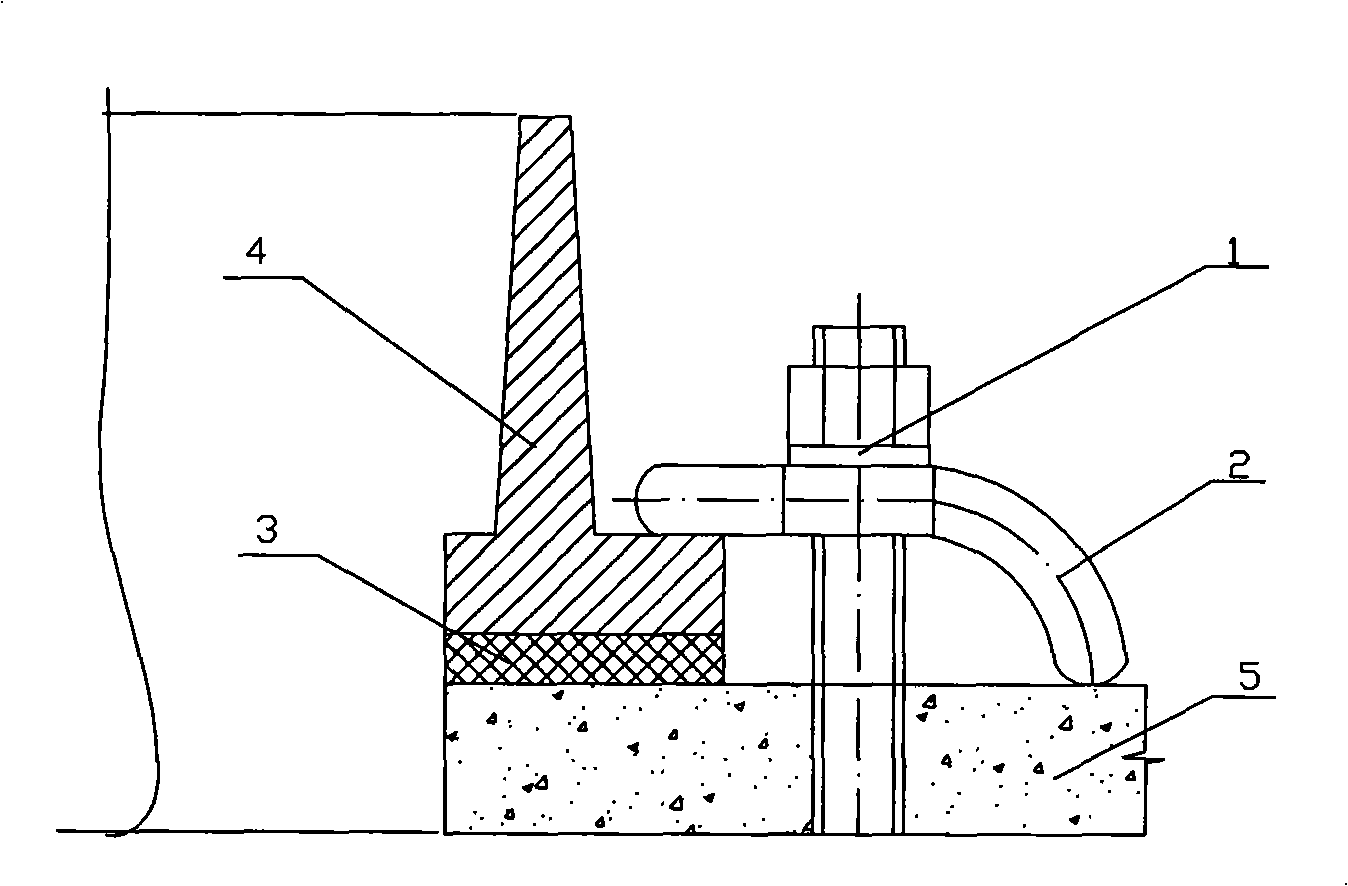

[0048] A kind of pressure plate type flexible manhole cover, comprises bull ear type well seat 4 (such as figure 1 , 2 shown), well cover, anchor bolt assembly 1, elastic pressure plate 2, three-oil two-net plastic gasket 3 and concrete well cap 5 (such as Figure 7 , 8 shown), not shown in the figure, it is better to adopt a cylindrical embedded connection structure between the ear-type well seat 4 and the well cover, the height of the cylindrical surface is 10mm-20mm, and the anchor bolt assembly 1 (composed of a screw rod and a nut The lower end (screw) of the composition) is anchored in the concrete well cap 5 and is located outside the ear-type well seat 4, and the three-oil-two-network plastic gasket 3 is installed between the ear-type well seat 4 and the concrete well cap 5, The elastic pressure plate 2 is set on the anchor bolt assembly 1, one end of which is against the bull ear on the bull ear well seat 4, and t...

Embodiment 2

[0050] Such as figure 1 , 2 , 4, 7, and 8.

[0051] A pressure plate type rigid manhole cover, which is mainly composed of a well cover (not shown in the figure), a bull ear type well seat 4, an anchor bolt assembly 1, a rigid pressure plate 6, and a concrete well cap 5, such as Figure 4 As shown, the lower end of the anchor bolt assembly 1 (mainly composed of a screw and a nut, the specification should be greater than 3×Φ12mm) is anchored to the concrete well cap 5 (such as Figure 7 , shown in 8, the ring height can be 250mm, and the ring width can be 250mm) and is located in the cow ear type well seat 4 (such as figure 1 , shown in 2) on the outside, the cow ear type well seat 4 is directly supported on the concrete well cap 5, and the rigid pressure plate 6 (also refer to Figure 5 , 6The form of making, top view is " 8 " shape structure) is sleeved on the anchor bolt assembly 1, and its one end and the cow ear on the bull ear type well seat 4 offset, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com