Novel anti-rutting agent

An anti-rutting agent, a new type of technology, applied in the field of new anti-rutting agents, can solve the problems of weak anti-rutting ability, achieve low cost, safe and convenient use, and improve low-temperature cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

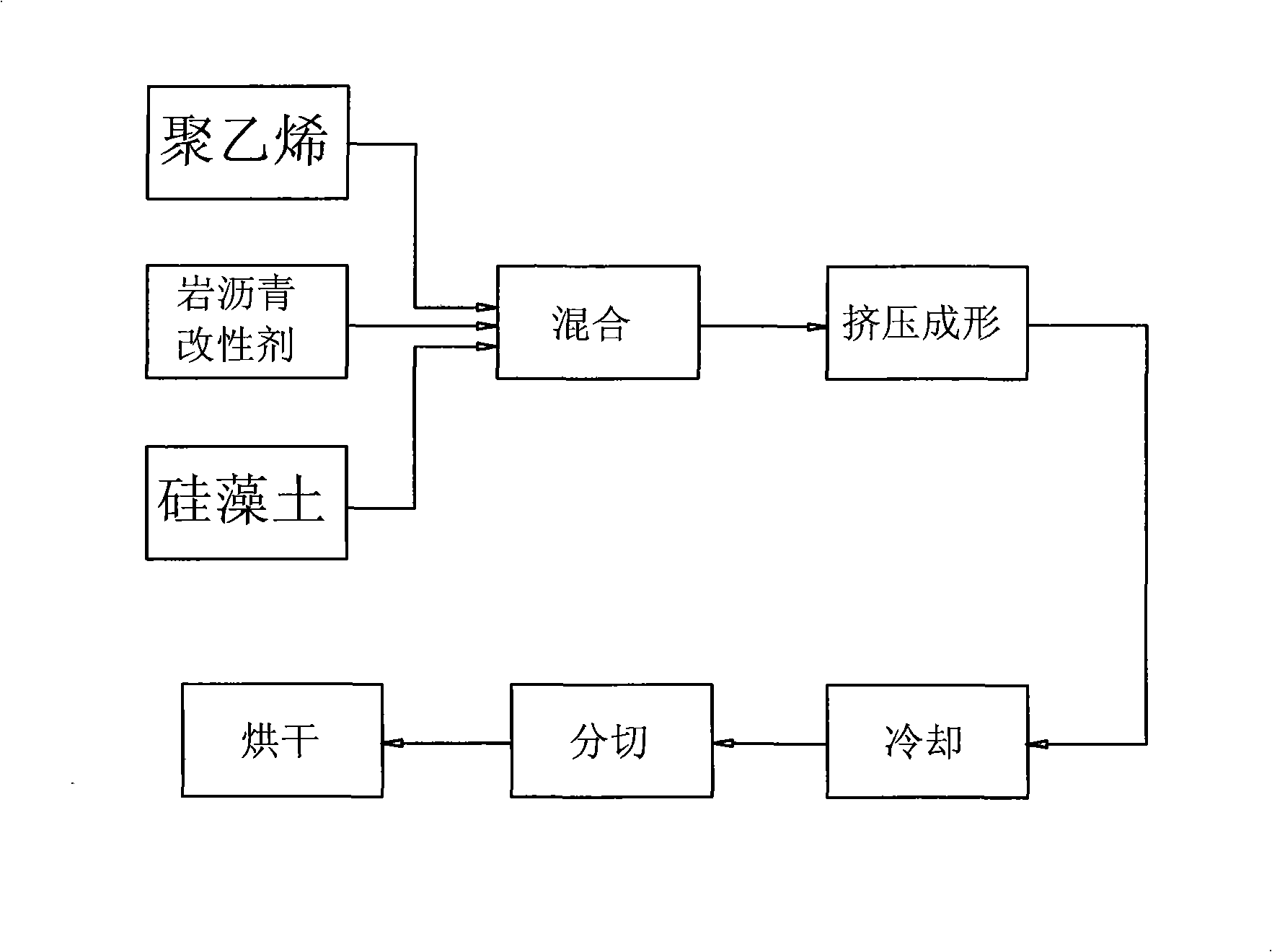

Method used

Image

Examples

Embodiment 1

[0024] First take 3000g of rock asphalt with a particle size of 400 mesh, 4500g of recycled polyethylene (RPE, waste film with a side length or radial dimension of about 10mm) and 2500g of diatomite with a particle size of 400 mesh. Weigh and add quantitatively to the screw extruder for blending and extrusion (the processing extrusion temperature is 160° C.), to form a strip-shaped semi-finished product. Then through water cooling (water temperature is lower than 20°C), wheel cutter slitting and granulation (particle size 3-4mm), and drying in a drying device for one hour (temperature 80°C), the novel anti-bacterial agent of the present invention can be obtained. Finished rutting agent.

Embodiment 2

[0026] First take 2500g of 400-mesh rock asphalt and 3000g of diatomite with similar particle size, and 4500g of low-density polyethylene (LDPE) (particle size is less than 1mm), after mixing (the method is the same as above), and metering into the screw extruder for co-extrusion (processing The extrusion temperature is 150° C.) to form a strip-shaped semi-finished product. Then through water cooling (water temperature is lower than 20°C), wheel cutter slitting and granulation (particle size 3-4mm), and drying in a drying device for one hour (temperature 80°C), the novel anti-bacterial agent of the present invention can be obtained. Finished rutting agent.

Embodiment 3

[0028] Raw material adopts rock pitch 3000g, polyvinyl chloride (PVC) 5000g and diatomite 2000g, and other methods and process parameters are the same as embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com