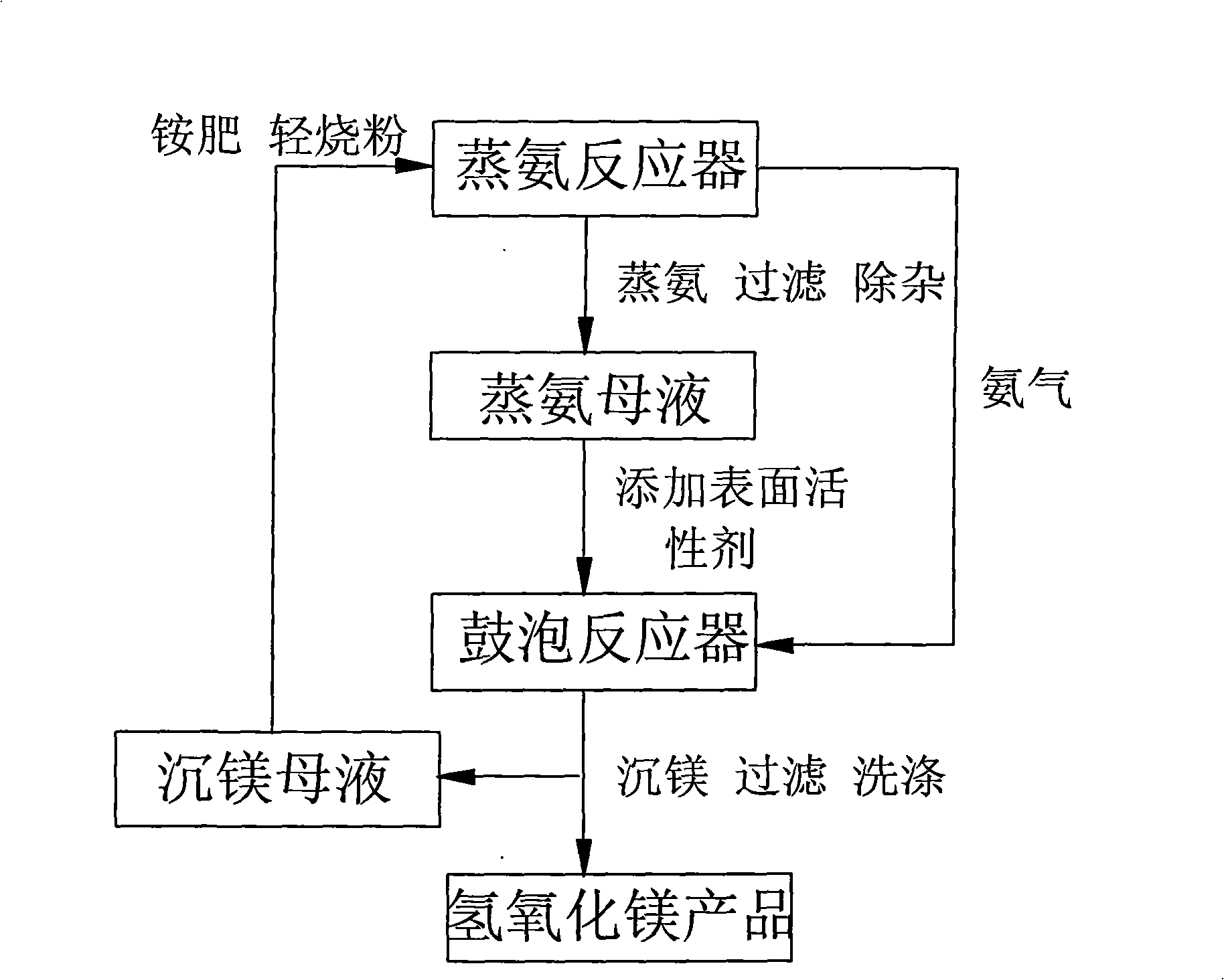

Method for preparing uniform granular magnesium hydrate by one-step reaction with ammonia bubbling method

A technology of magnesium hydroxide and particle shape, applied in magnesium hydroxide and other directions, can solve the problems of poor consistency of magnesium hydroxide product particles, non-uniform product crystal form, harsh production conditions, etc., to save raw material transportation costs, optimize macro and Micro mixing effect, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 7kg of ammonium sulfate to prepare 30L of aqueous solution, adjust it to 19% aqueous solution, add lightly burned powder, adjust the pH value of the solution to 7 as the reaction liquid, enter the ammonia distillation reactor for ammonia distillation reaction, and the ammonia distillation temperature is 105°C. The ammonia gas produced is sent to the bubble reactor, and the precipitate is filtered to remove Fe 3+ 、Al 3+ Impurities, to obtain magnesium sulfate solution. Add the above magnesium sulfate solution into the bubbling reactor, adjust the temperature at 45°C, and directly pass ammonia gas into the reaction liquid in the form of bubbling, the flow rate of ammonia gas is 0.06m 3 / h, the pH at the end of the reaction was 9.5, and a milky white suspension of magnesium hydroxide and ammonium sulfate was obtained. Keep warm for 2 hours and then lower to normal temperature for filtration. The obtained filter cake is washed with water for 3 times and dried at 80°C...

Embodiment 2

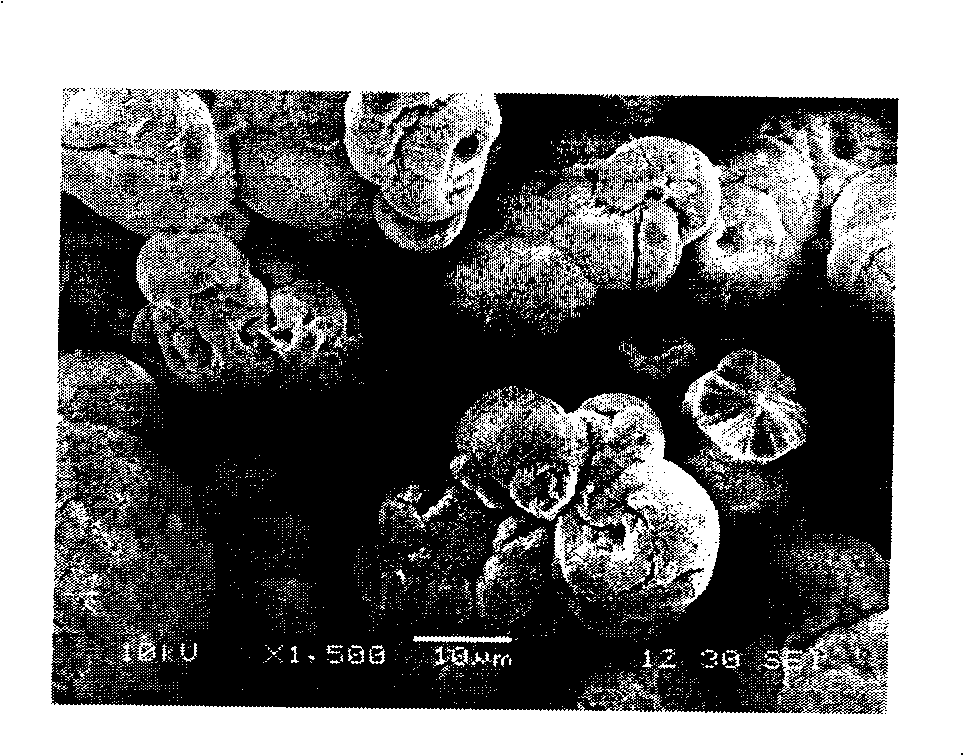

[0033] The process of ammonia distillation and impurity removal is the same as that in Example 1. Surfactant sodium dodecylbenzenesulfonate is added to the magnesium salt clarified filtrate in an amount of 0.3% of the mass of the magnesium salt clarified liquid, and vigorously stirred. Add the above magnesium salt solution into the bubbling reactor, adjust the temperature to 45°C, and directly pass ammonia gas into the magnesium salt solution in the form of bubbling, the flow rate of ammonia gas is 1.5m 3 / h, the pH value at the end of the reaction is 9.6, and the milky white suspension of magnesium hydroxide and ammonium salt is obtained, which is incubated for 3 hours and then lowered to normal temperature for filtration. The obtained filter cake is washed 3 times with clear water, dried at 80 °C for 12 hours, and a uniform particle shape is obtained. Magnesium hydroxide powder, the filtrate is returned to the ammonia distillation reactor, and lightly burned magnesium powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com