High-frequency ultrasonic transducer made of piezoelectric monocrystalline composite material as well as manufacturing method and application thereof

An ultrasonic transducer, piezoelectric single crystal technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, piezoelectric/electrostrictive/magnetic Stretchable devices and other directions can solve problems such as unfavorable high-frequency applications and achieve high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

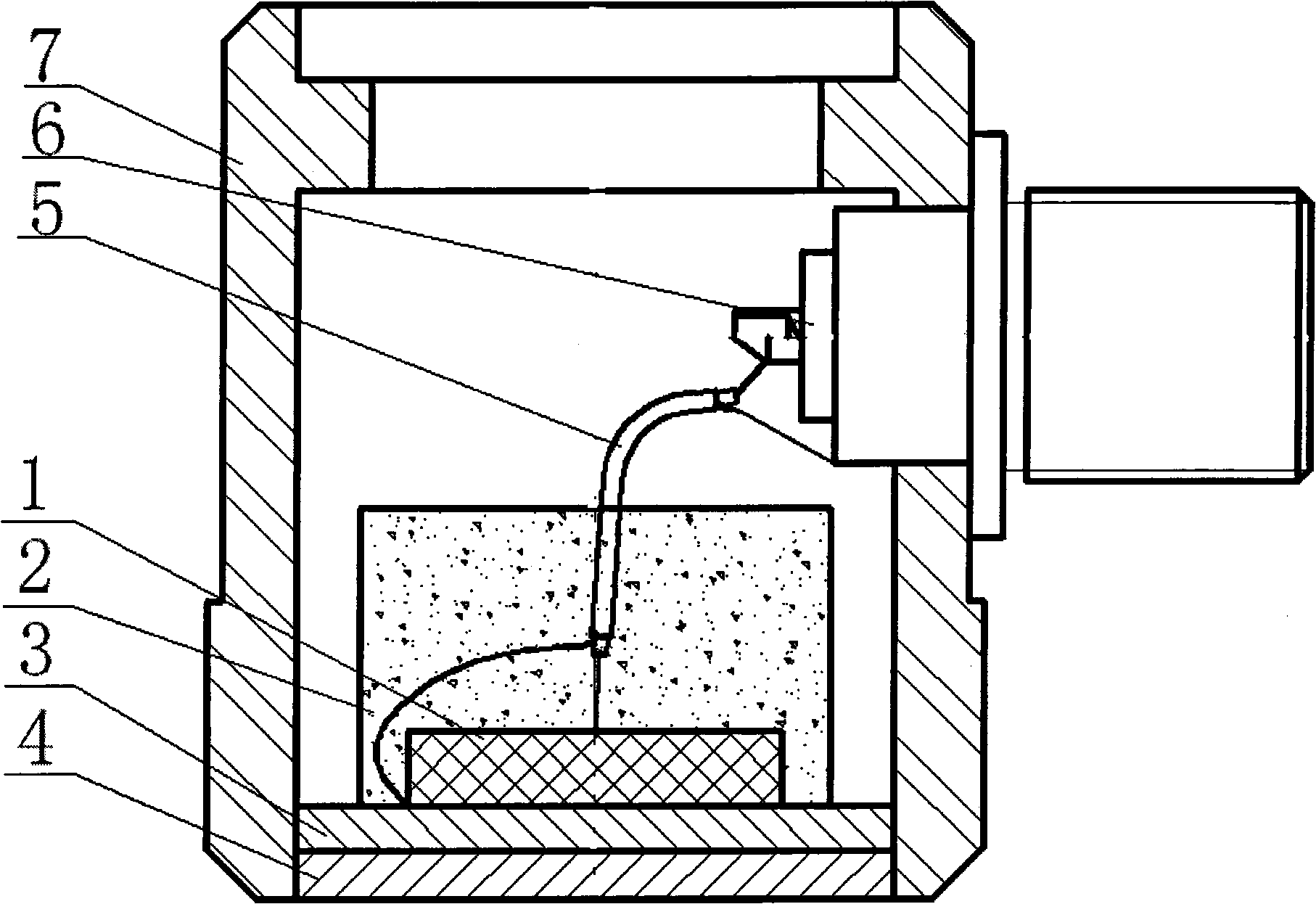

[0047] Such as figure 1 As shown, the piezoelectric single crystal composite material high-frequency ultrasonic transducer of the present invention includes a piezoelectric single crystal composite material wafer 1, a damping back material 2, a first matching layer 3, a second matching layer 4, and a coaxial electrode lead 5. Coaxial connector 6 and metal shell 7;

[0048] Piezoelectric single crystal composite material wafer 1 is lead magnesium niobate-lead titanate piezoelectric single crystal composite material or PZNT; second matching layer 4, first matching layer 3, piezoelectric single crystal composite material wafer 1, damping backing material 2 are bonded together in sequence to form an acoustic stack, and the coaxial electrode leads 5 are drawn from the positive and negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com