Rubber-fibre ball silencing board

A technology of sound-absorbing panels and steel fibers, which can be applied to noise absorbing devices, buildings, etc., can solve the problems of unfavorable driving safety, noise pollution, high manufacturing cost, etc., and achieve the effect of increasing sound-absorbing effect, good sound-absorbing effect and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

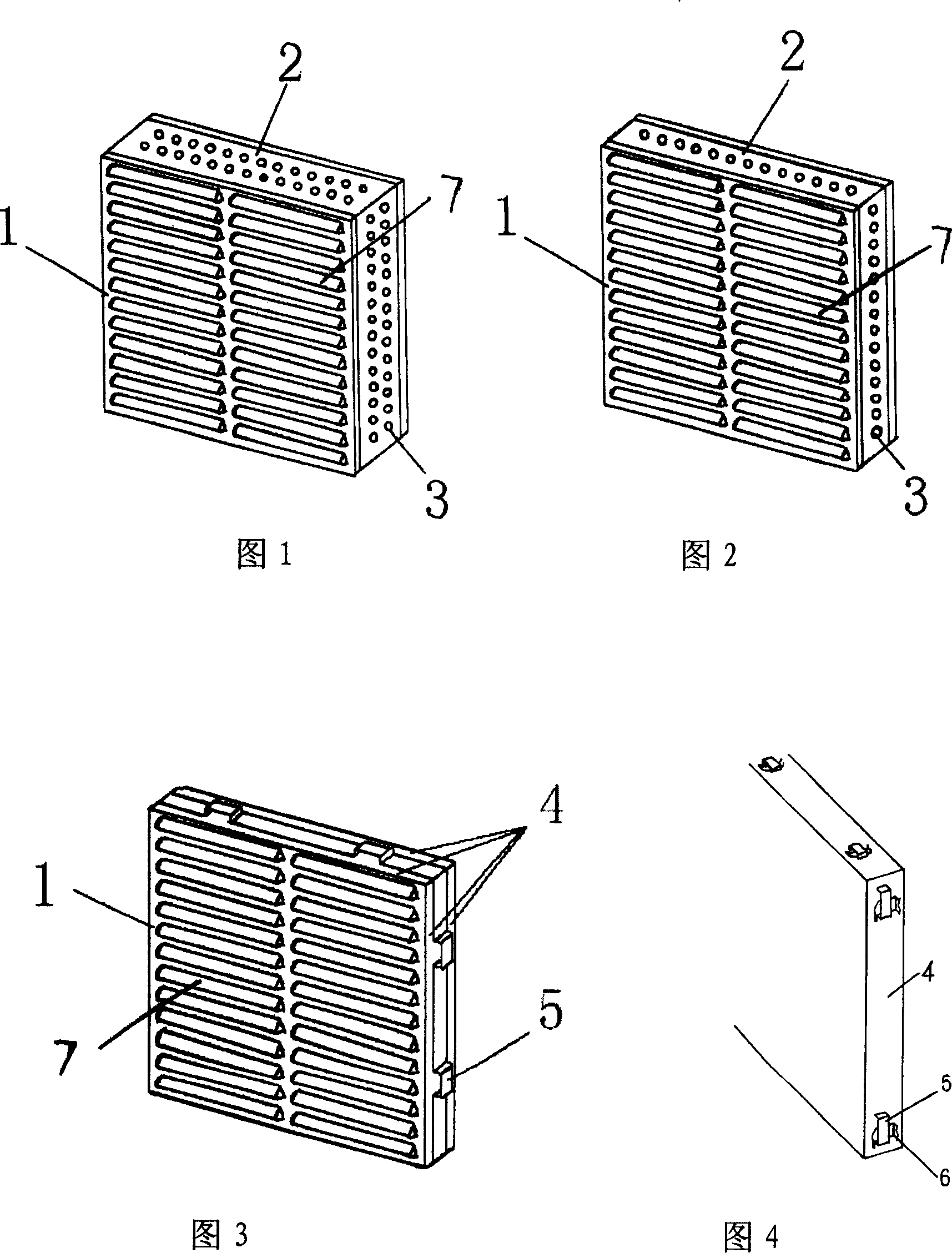

[0020] Embodiment 1: In Fig. 1, the sound-absorbing board has a main board, and spherical steel fiber balls 3 are distributed in the main board. This mainboard has foam rubber 2, and the hole of spherical steel fiber ball is distributed in foam rubber 2, and steel fiber ball 3 is positioned at the hole, and there is reflection bar 7 outside main board; Foam rubber is the foam rubber of surface hardening; Steel fiber The ball 3 is a sphere composed of metal wires irregularly, and is arranged in two layers. The main board is a flat plate; the main plate is a layer; the reflective strip is concave.

Embodiment 2

[0021] Embodiment 2: In Fig. 2, the foam rubber is surface-softened foam rubber, and the outer end face is connected with a surface layer; the steel fiber ball is a sphere composed of metal strips randomly, arranged in one layer. The main board is a flat plate; the main pulley is a layer; the reflection strips are protruding. Others are the same as in Embodiment 1, omitted.

Embodiment 3

[0022] Embodiment 3: In Fig. 3 and Fig. 4, the frames of all boards are two rigid mounting frames 4 that are not directly connected, and there are mounting ears 5, screw holes and mounting hooks 6 on them for quick connection. The mounting ears 5 are located on the right side and the upper side of the body; the mounting hooks 6 are located on the left side and the lower side of the body.

[0023] When in use, fix the backboard on both sides of the road, and connect the sound-absorbing board to the backboard through fixing bolts. There is a space layer between the sound-absorbing plate and the back plate, and the space layer is a reflection filter, which can reduce the noise of a specific frequency band.

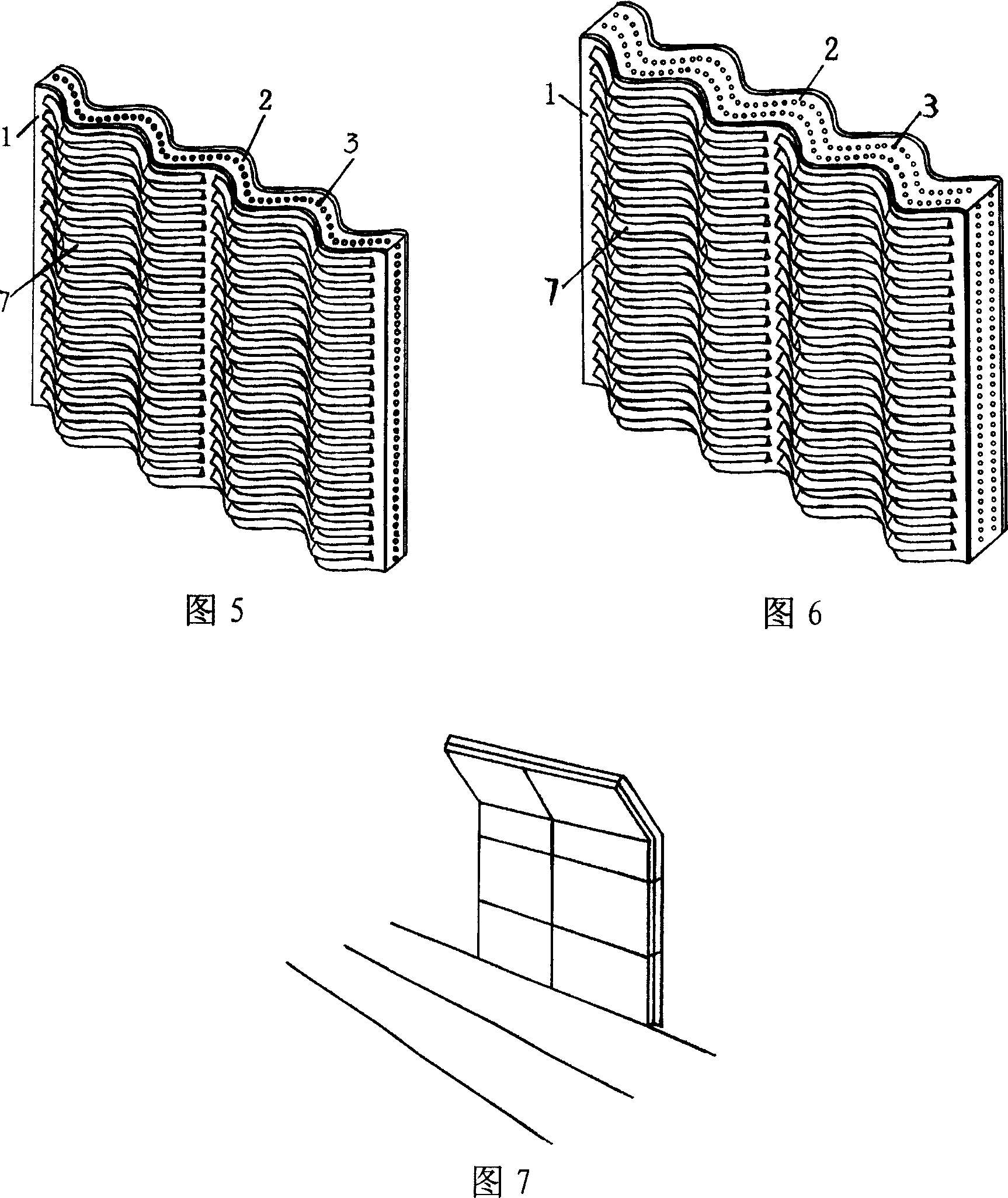

[0024] A layer of sound-absorbing steel fiber is wrapped with two surface layers and directly connected to the backboard, and the main board is a corrugated board. Others are the same as in Embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com