High-voltage electrostatic dust separator for industrial furnace

A high-voltage electrostatic and dust collector technology, applied in the direction of electrostatic separation, steam flow control, etc., can solve the problems of low dust removal efficiency, large size of dust collector, uneven distribution of smoke and dust, etc., to achieve improved dust collection efficiency, convenient operation and management, and collection effect of dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

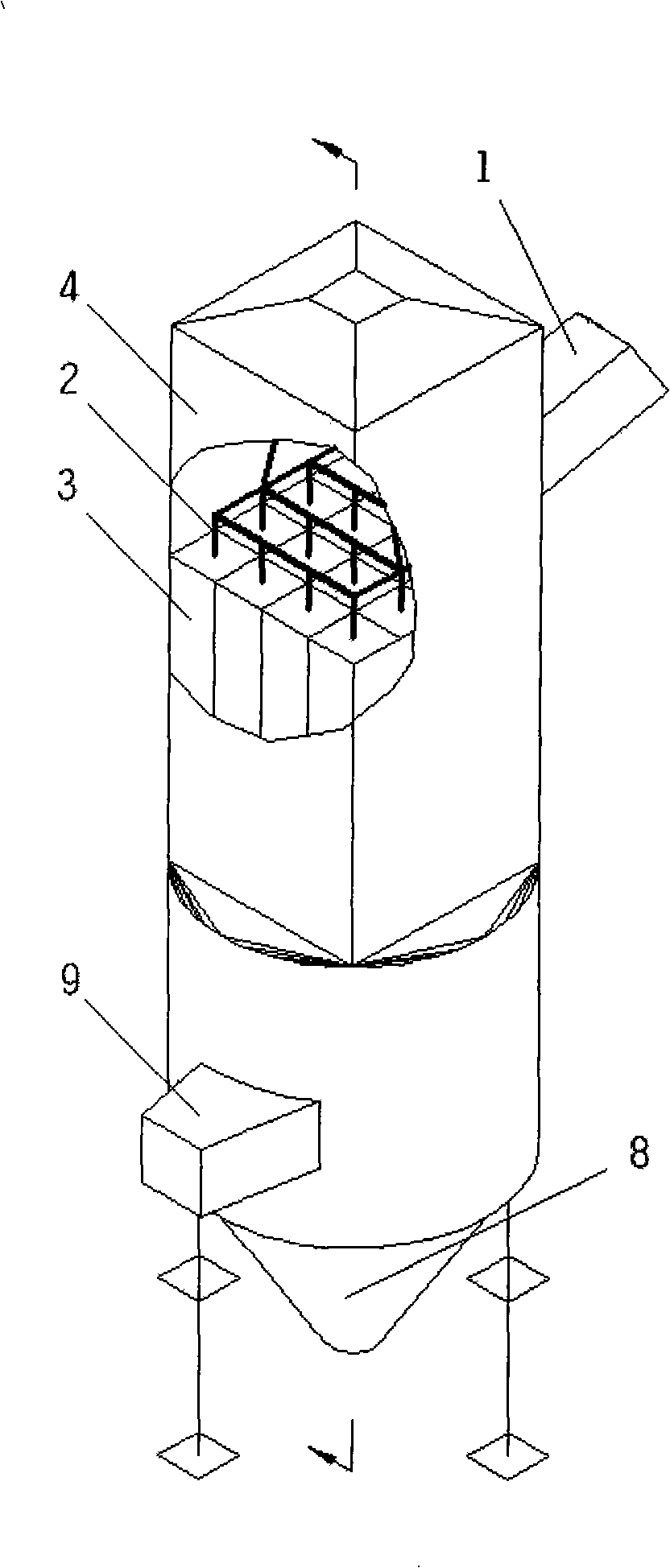

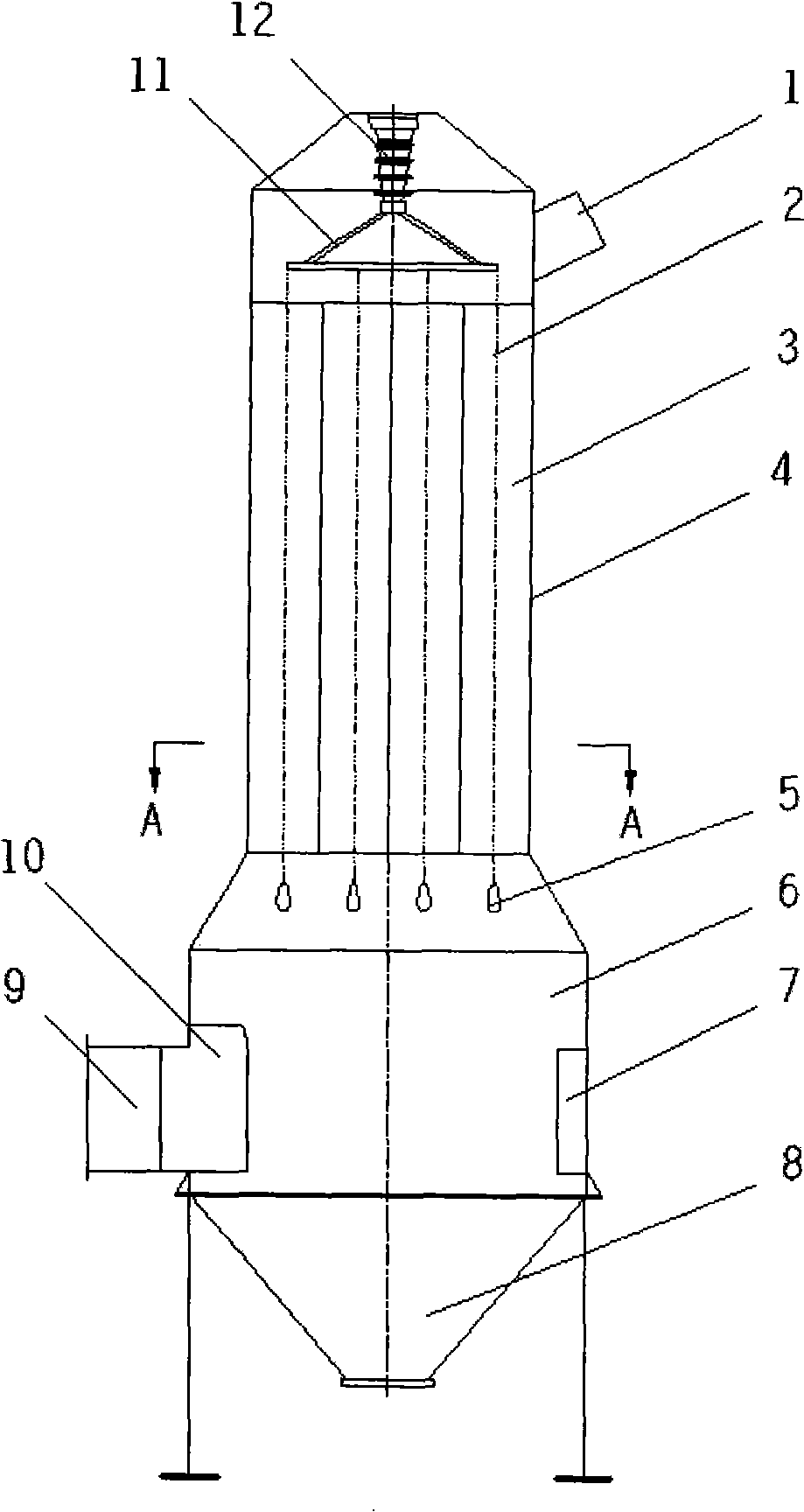

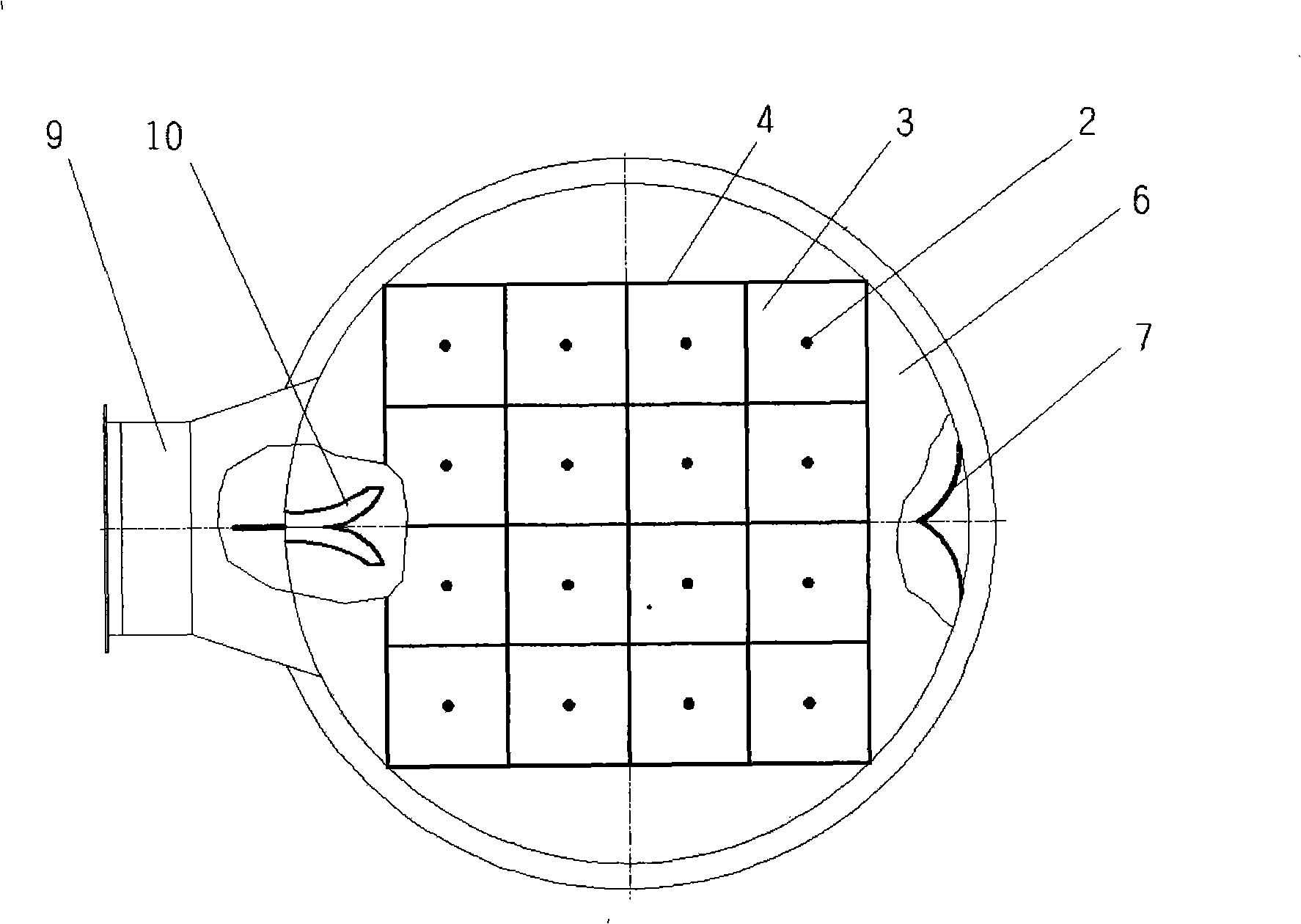

[0017] figure 1 , 2 , 3 is the structural representation of the high-voltage electrostatic precipitator for industrial kiln of the present invention, it is provided with air inlet 9 and air outlet 1, and its dedusting electric field is made of a plurality of standpipe 3 inner walls as dust collecting pole plate, and corona wire 2 It is arranged in the center of the standpipe, the high-voltage insulating porcelain bottle 12, and the hanger 11 of the corona wire group are arranged above the standpipe. One end of the tuyere 9 is connected to the smoke and dust discharge pipe of the industrial kiln, and the other end is connected to the air equalizer 6, and the lower part of the air equalizer 6 is connected to the dust collector hopper 8, and the air inlet 9 connected to the air equalizer 6 is provided with a swirling deflector 10 Extending to the inside of the air equalizer, the other side of the air equalizer 6 corresponds to the extension line of the swirling deflector 10 to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com