Lubricating oil composition

A lubricating oil composition and technology of the composition, applied in the direction of lubricating composition, petroleum industry, base materials, etc., can solve problems such as engine oil corrosion, and achieve the effect of improving oxidation stability and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples.

[0095] Lubricating oil compositions having the compositions shown in Table 1 were prepared, and subjected to the following reciprocating friction test, oxidation degradation test, and lead corrosion test. The results are shown in Table 2. In addition, the types of each component used to prepare the lubricating oil composition are as follows.

[0096] (1) Base oil A: hydrotreated base oil, kinematic viscosity at 40°C is 21mm 2 / s, kinematic viscosity at 100°C is 4.5mm 2 / s, viscosity index is 127, %C A 0.1 or less, the sulfur content is less than 20 mass ppm, and the NOACK evaporation is 13.3 mass %

[0097] (2) Ester friction modifier A: Glyceryl monooleate

[0098] (3) Amide friction modifier B: Oleic acid diethanolamide

[0099] (4) Amine friction modifier C: Kikulu-bu FM910 (manufactured by ADEKA Co., Ltd.)

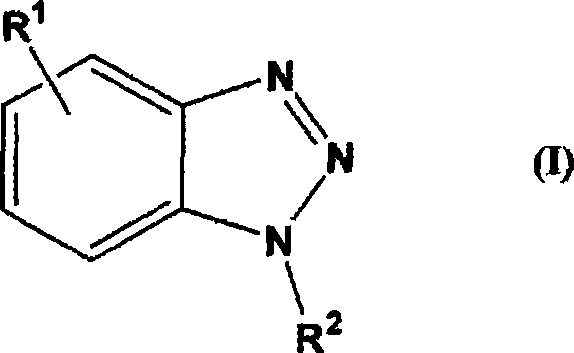

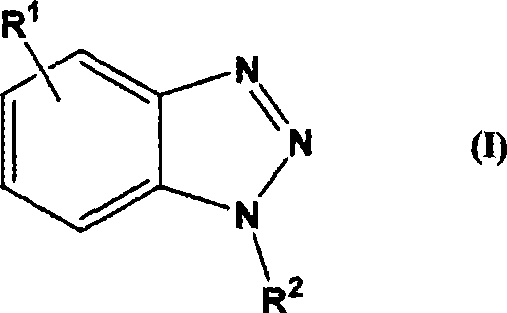

[0100] (5) Benzotriazole compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com