Method of metal sheet press forming and skeletal part for vehicle produced thereby

A stamping forming and metal plate technology, which is applied to frame members for skeleton structure vehicles, known as the stamping field of drawing forming, can solve problems such as low cost and achieve the effects of low cost, improved forming limit and easy application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

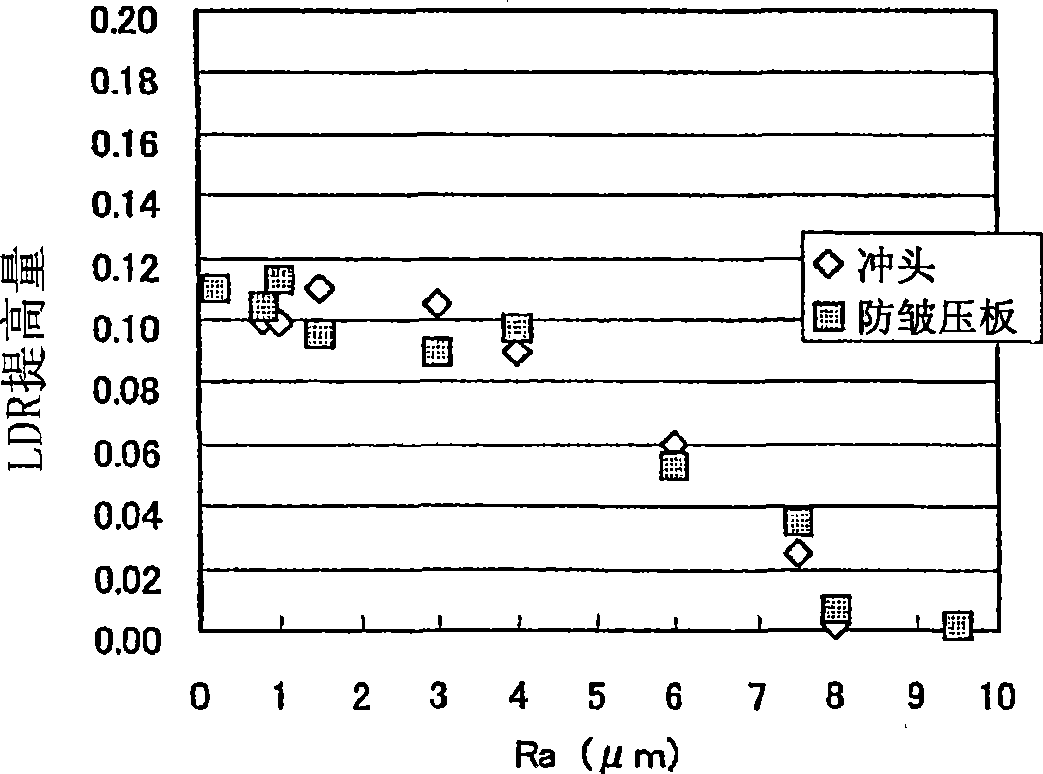

[0091] Forming tests were conducted by varying the surface roughness of punches, dies, and wrinkle-preventing platens and the kinematic viscosity of lubricants. Cylindrical cup forming was carried out using a cold-rolled steel sheet having a tensile strength of 440 MPa of the code B shown in Table 1 as a test material.

[0092] The punch 10 has a diameter φ of 33 mm and a shoulder radius of 3 mm. The shoulder radius of the die 20 is 5 mm. The evaluation of the forming limit in the cylindrical cup drawing forming uses LDR (Limited Drawing Ratio).

[0093] Table 1

[0094] Mechanical properties of the test material

[0095] label YP (MPa) TS(MPa) EL(%) Plate thickness (mm) A 151 280 48 1.2 B 323 470 32 1.2 C 630 1035 10 1.2

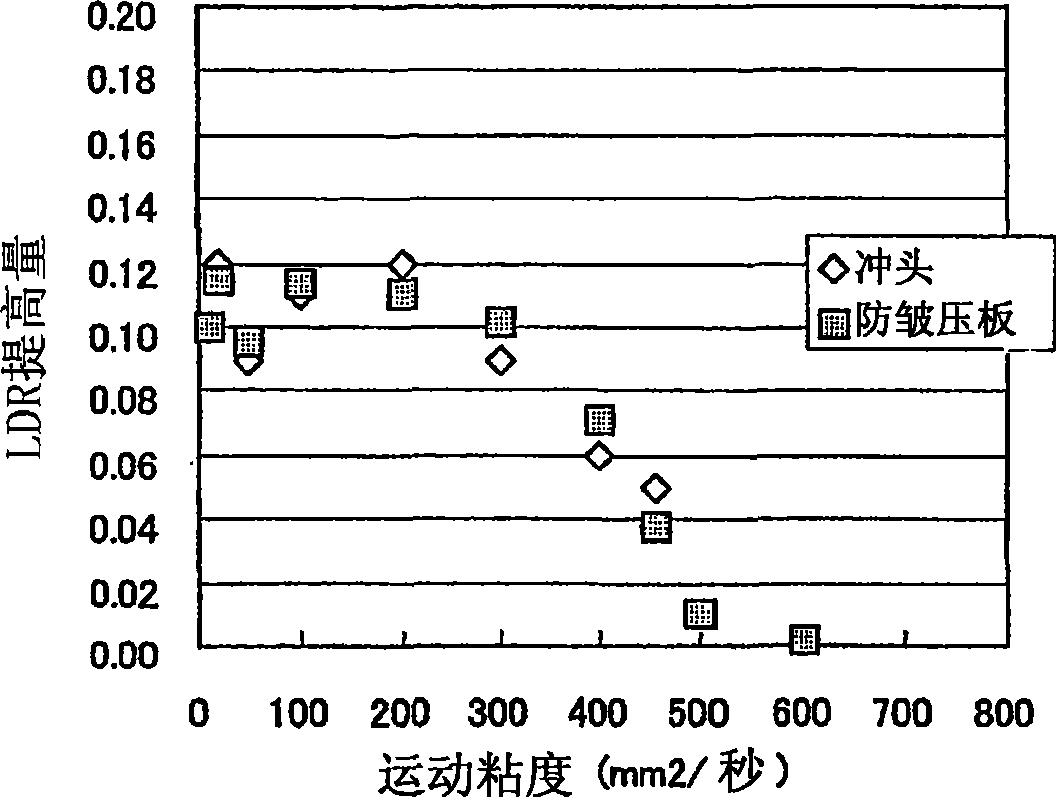

[0096] First, a forming test was carried out using a metal mold having a surface whose arithmetic mean roughness Ra was 1.0 μm, and using several types of lubricants with varying kinematic viscosities. In t...

Embodiment 2

[0100] Press forming was performed using two types of cold-rolled steel sheets B and C shown in Table 1. The test material B is a cold-rolled steel plate with a tensile strength of 440MPa, and the test material C is a cold-rolled steel plate with a tensile strength of 980MPa.

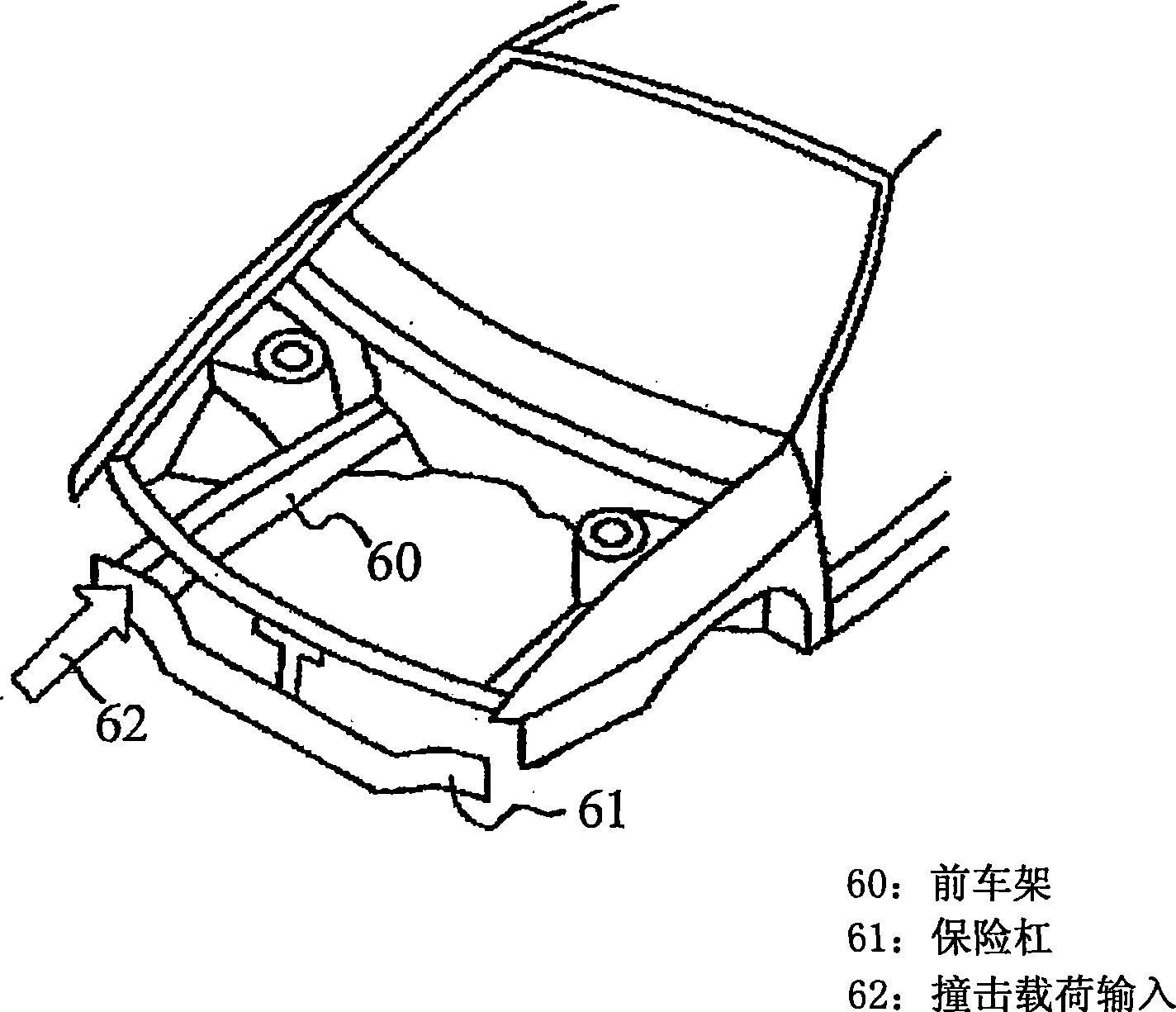

[0101] The object member is image 3 Shown is a front frame 60 as one of the frame members for the vehicle. Such as image 3 As shown, the front frame 60 is a member that functions to absorb energy (indicated as impact load input) 62 when the front of the vehicle collides. Therefore, it should be an important member having excellent energy absorption characteristics. image 3 Among them, 61 is a bumper.

[0102] The backing plate is spot-welded on the back of the drawn stamping product to make a closed-section structural member, and the compression failure test of the member is carried out. The test piece B1 is a member formed by using the test material B by a conventional forming method, and the te...

Embodiment 3

[0107] Three types of cold-rolled steel sheets shown in Table 1 were used to form cylindrical cups.

[0108] The test material A is a cold-rolled steel plate with a tensile strength (TS) of 270MPa, the test material B is a cold-rolled steel plate with a tensile strength (TS) of 440MPa, and the test material C is a cold-rolled steel plate with a tensile strength (TS) of 980MPa .

[0109] The punch 10 has a diameter φ of 33 mm and a shoulder radius of 3 mm. The shoulder radius of the die 20 is 5mm. The evaluation of the forming limit in the cylindrical cup drawing forming uses LDR (Limited Drawing Ratio).

[0110] Use a metal mold with an arithmetic mean roughness Ra of 1.0 μm on the surface, and apply a kinematic viscosity of 20mm 2 / sec anti-rust oil as a lubricant to carry out the cylindrical cup forming test. The three types of forming according to the present invention are conventional conventional forming methods, temporarily separating the punch from the blank during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com